Why the Golden Template is Essential for Effective Anomaly Detection

Published on: Nov 19, 2024

Written by: Soumen das

Why the Golden Template is Essential for Effective Anomaly Detection

Anomaly detection is a key process in many industries, enabling organizations to identify unusual patterns that may indicate errors, defects, or potential failures. One effective approach within this domain is the concept of a "Golden Template." This template serves as a standard against which real-time data is compared to detect anomalies, such as defects or deviations. By establishing a precise benchmark, the Golden Template helps in maintaining quality, ensuring consistency, and enabling efficient detection of issues, making it essential for industries focused on accuracy and reliability.

What is a Golden Template?

A Golden Template is a high-precision reference model or dataset representing the "ideal" or "normal" state of a product. Often created from multiple high-quality samples or thorough statistical analyses, the Golden Template serves as the benchmark to which future samples are compared in order to identify any deviations or anomalies. Essentially, it acts as the standard of perfection, and any variation from this template can signal a potential anomaly.

The Golden Template approach is widely used in industries that require high accuracy and quality control, such as manufacturing, automotive, electronics, and pharmaceuticals. By having a standard or “perfect” reference, companies can efficiently detect inconsistencies that may lead to defects, quality issues, or system failures.

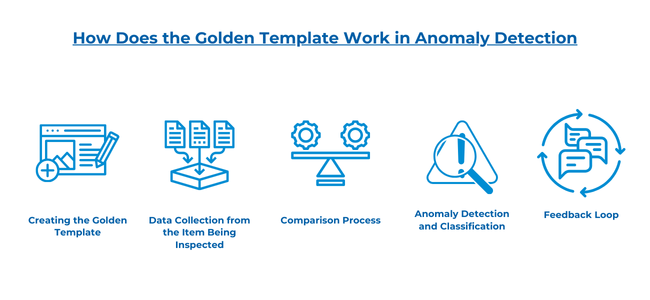

How Does the Golden Template Work in Anomaly Detection?

The Golden Template functions as a baseline for anomaly detection by capturing the characteristics of a defect-free, high-quality sample or system. Anomaly detection based on this template typically involves the following steps:

- Creating the Golden Template: The template is built by collecting data from a large set of ideal samples. This could include dimensions, shapes, weight, color, or other features, depending on the object or process being monitored. Advanced technologies such as 3D scanning, machine learning, and statistical analysis are often used to build a comprehensive template.

- Data Collection from the Item Being Inspected: The system then captures real-time data from the item being inspected, often through sensors, cameras, or other monitoring devices. This data is compared against the Golden Template in real time.

- Comparison Process: The system measures the differences between the Golden Template and the item in question. These differences may include minor variances due to natural variability, but significant deviations signal potential anomalies.

- Anomaly Detection and Classification: If a deviation exceeds predefined thresholds, it is flagged as an anomaly. In sophisticated systems, anomalies can be classified by type or severity to inform the necessary corrective action.

- Feedback Loop: In some applications, the anomaly detection system includes a feedback loop that allows it to improve the Golden Template over time, especially in systems that undergo slight natural variation.

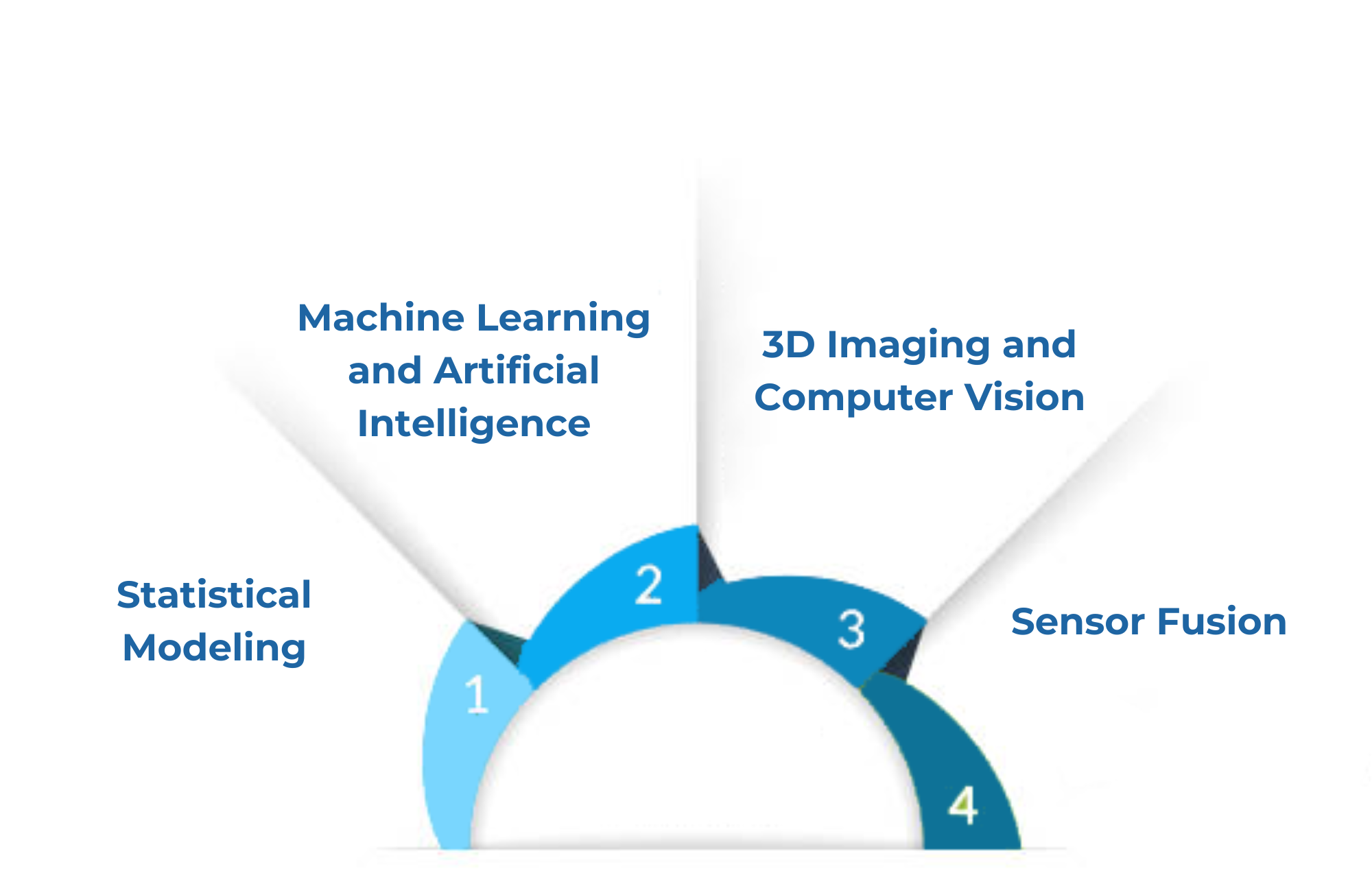

Techniques for Building a Golden Template

Creating an effective Golden Template requires robust data collection and modeling techniques. Some commonly used methods include:

- Statistical Modeling: Statistical techniques help in establishing acceptable limits for variability, setting thresholds for what constitutes an anomaly. This modeling often includes calculating averages, standard deviations, and distribution ranges from multiple samples.

- Machine Learning and Artificial Intelligence: Machine learning algorithms can be trained on large datasets of "normal" samples to identify subtle variations and learn complex patterns. Once trained, these models create a highly detailed Golden Template that can recognize anomalies in new data.

- 3D Imaging and Computer Vision: In industries like manufacturing, 3D imaging and computer vision techniques are used to capture high-resolution models of objects. These methods allow the system to detect physical anomalies such as cracks, distortions, or other surface imperfections by comparing the item with the Golden Template.

- Sensor Fusion: In complex systems, data from multiple sensors (e.g., temperature, pressure, vibration) can be combined to create a comprehensive Golden Template, which captures the ideal operational state across multiple dimensions.

Applications of the Golden Template in Anomaly Detection

The Golden Template is a versatile concept that finds applications in a wide range of industries:

1. Manufacturing Quality Control

In manufacturing, the Golden Template approach is used to detect defects in products as they move along the production line. For example, in the electronics industry, components such as circuit boards must adhere to strict quality standards. A Golden Template model can detect slight deviations in soldering, component placement, or circuit pathways, ensuring defective parts are identified and removed from the production line.

2. Automotive Industry

The automotive industry relies on high standards of safety and performance, and anomaly detection based on Golden Templates is essential. For instance, during the assembly of an engine or transmission system, real-time comparisons with a Golden Template can detect misalignments, missing parts, or other assembly errors. Similarly, the Golden Template can also be used for surface inspection, identifying scratches or dents on car bodies.

3. Aerospace Engineering

In aerospace, where quality and precision are paramount, anomaly detection is critical. Golden Templates are used to inspect complex components like turbine blades, where even a minor imperfection could have serious consequences. High-precision imaging and data analysis ensure that parts conform to strict standards, detecting any deviation that may compromise performance or safety.

4. Healthcare and Medical Devices

For medical devices, the Golden Template can be used to ensure the quality of equipment, implants, and consumables such as syringes or tubing. Any deviation from the template can indicate manufacturing defects, which could impact patient safety. In healthcare, anomaly detection based on Golden Templates can also be applied in diagnostic imaging to identify deviations that may signal abnormal or pathological conditions.

5. Food and Beverage Industry

Quality control in food and beverage production often involves comparing samples against a Golden Template to ensure products meet safety and quality standards. For example, the color, shape, and size of fruits, vegetables, or processed foods can be compared to a standard template to detect items that do not meet required specifications, ensuring consistency and safety in the final product.

6. Electronics and Semiconductor Manufacturing

In semiconductor fabrication, the Golden Template is used to detect microscopic defects in wafers or chips. Using advanced imaging and machine learning, manufacturers can ensure the layout and structure of semiconductor components match the ideal template, detecting defects early in the process to prevent costly failures.

Benefits of Using a Golden Template in Anomaly Detection

The Golden Template approach to anomaly detection offers several benefits:

- High Precision: By comparing items to an ideal template, the system can detect minute deviations that might go unnoticed through traditional inspection methods.

- Automated and Real-Time Detection: Golden Template-based systems allow for continuous monitoring and immediate detection of anomalies, reducing the need for manual inspection and speeding up the production process.

- Improved Product Quality: Since anomalies are detected early in the process, defective products are removed from the production line before reaching consumers, resulting in higher-quality output.

- Cost Savings: Early detection reduces the costs associated with waste, rework, and product recalls, while automated anomaly detection systems reduce labor costs.

- Consistency and Reliability: Golden Template anomaly detection systems maintain consistency by adhering to a standardized quality model, ensuring uniform quality across products.

Challenges in Implementing Golden Template-Based Anomaly Detection

Despite its advantages, implementing a Golden Template for anomaly detection comes with challenges:

- Template Variability: Slight, acceptable variations may occur in any process or product. Defining the acceptable range of deviation without compromising quality or rejecting acceptable products is challenging.

- Data Collection and Template Accuracy: Building an accurate Golden Template requires high-quality data from defect-free samples. Any errors in data collection or template creation can lead to false positives or missed anomalies.

- Adaptability to Changes: For processes or products that evolve over time, the Golden Template may need to be periodically updated. Keeping the template relevant can be time-consuming and resource-intensive.

- False Positives and Negatives: Too narrow of a tolerance range may lead to false positives, while a range that’s too broad can miss critical defects. Balancing sensitivity is crucial to accurate anomaly detection.

- High Initial Costs: Implementing a Golden Template approach often requires investment in advanced technologies like machine learning, computer vision, or 3D imaging. For smaller companies, these costs may be prohibitive.

Future Trends in Golden Template Anomaly Detection

The future of Golden Template-based anomaly detection will likely involve advancements in AI and machine learning, enhancing the accuracy, adaptability, and scalability of the approach. Emerging trends include:

- Adaptive Templates: Future systems could create adaptive Golden Templates that evolve in response to production changes or new quality requirements, reducing the need for frequent manual updates.

- Integration with IoT and Edge Computing: Integrating the Golden Template approach with IoT and edge computing will enable real-time data processing and anomaly detection closer to the production line, reducing latency and improving efficiency.

- Self-Learning Systems: AI-driven anomaly detection systems may become capable of self-learning, allowing them to refine the Golden Template over time without human intervention, based on observed variations.

- Enhanced Visualization and Analytics: Advanced analytics and visualization tools will offer better insights into anomalies, making it easier for operators to understand and address issues in real time.

The Golden Template is a powerful tool in anomaly detection, providing a high-precision reference model for quality control across numerous industries. By comparing real-time data against an ideal standard, companies can ensure consistency, improve quality, and reduce waste. However, successful implementation requires careful planning, data accuracy, and a well-calibrated tolerance for acceptable deviations. As technology advances, the Golden Template approach will continue to evolve, delivering even greater benefits to industries reliant on high standards of quality and reliability.