Why Line Scan Cameras Are Essential for Moving Line Inspection

Published on: Feb 14, 2025

Written by: Content team, Intelgic

Why Line Scan Cameras Are Essential for Moving Line Inspection

In the realm of industrial automation and quality assurance, precise and high-speed inspection of moving production lines is critical. Traditional area scan cameras, while effective in static applications, often fall short when it comes to capturing images of fast-moving objects with high precision. This is where line scan cameras emerge as an indispensable technology. Their unique scanning methodology and advanced image processing capabilities make them ideal for applications requiring continuous, high-resolution imaging of products in motion.

Necessity of Line Scan Camera for Moving Line Inspection

Manufacturing environments, particularly those involving high-speed conveyor belts, rely heavily on automated machine vision systems to detect defects, ensure product consistency, and optimize quality control. A line scan camera is specifically designed for such scenarios due to its ability to capture a continuous image of objects passing through its field of view. Unlike area scan cameras, which capture entire frames at once, line scan cameras acquire images line by line, seamlessly stitching them together to create a detailed composite image of the moving object. This capability offers significant advantages:

- High-Speed Imaging: Line scan cameras can achieve exceptionally high line rates, often exceeding hundreds of kilohertz, enabling them to inspect products moving at extremely fast speeds without motion blur.

- Superior Image Quality: The continuous nature of image acquisition allows for uniform illumination and exposure control, eliminating inconsistencies associated with area scan cameras.

- Extended Field of View: Line scan cameras facilitate the inspection of wide or continuous materials, such as rolls of paper, textiles, metal sheets, and glass.

- Efficient Processing: These cameras generate less redundant data compared to area scan cameras, enabling faster processing and reduced storage requirements.

- Seamless Defect Detection: Line scan imaging is particularly beneficial for identifying small defects, scratches, or inconsistencies in high-resolution formats.

How a Line Scan Camera Works in a Fast-Moving Line

The core principle of a line scan camera is to capture a single line of pixels at a time as the object moves past the camera sensor. These individual lines are then combined in sequence to form a complete two-dimensional image. This unique imaging approach makes line scan technology particularly well-suited for inspecting continuous or high-speed production lines.

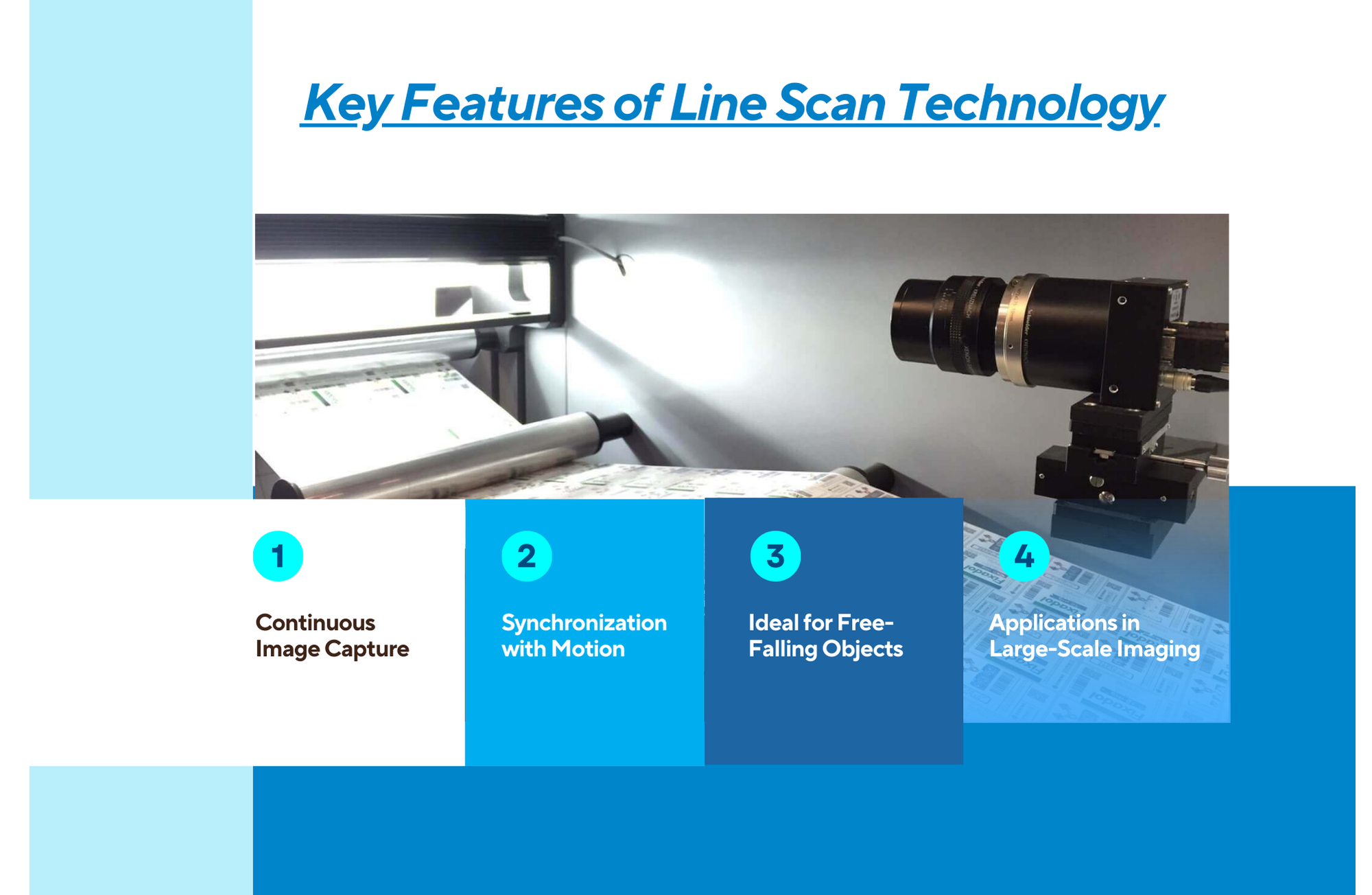

Key Features of Line Scan Technology:

- Continuous Image Capture: Since only a single row of pixels is acquired at any given instant, there are no interruptions or frame gaps, ensuring a continuous, distortion-free image.

- Synchronization with Motion: The camera is synchronized with the speed of the moving line using an encoder, ensuring precise image reconstruction and accurate defect detection.

- Ideal for Free-Falling Objects: Line scan cameras excel in scenarios where products are falling freely, such as molten glass and steel, as well as for postal sorting applications.

- Applications in Large-Scale Imaging: This technology is widely used in railway track inspection, road monitoring, satellite imaging, and surface topography scanning, where large, high-resolution images are required.

One of the defining advantages of line scan cameras over area scan cameras is the ability to compensate for short exposure times through advanced illumination techniques and Time Delay and Integration (TDI). TDI significantly increases the amount of light (photons) collected by the sensor, thereby enhancing image quality even at extremely high speeds. Furthermore, while area scan cameras rely on the system’s CPU for gain and offset correction, line scan cameras handle these corrections internally, reducing processing load and enhancing efficiency.

How to Select the Right Line Scan Camera for Your Application

Selecting the appropriate line scan camera for a specific application requires careful consideration of several key factors. These include:

- Resolution Requirements: The resolution of the camera should align with the smallest defect size that needs to be detected. Higher resolution sensors capture finer details but require more processing power.

- Line Rate: The line rate should match the speed of the moving line to ensure high-quality image reconstruction without distortion.

- Pixel Size and Sensor Sensitivity: Choosing the right pixel size impacts light sensitivity and image clarity, particularly in low-light environments.

- Interface and Connectivity: Different applications may require specific communication interfaces such as Camera Link, GigE Vision, or CoaXPress for high-speed data transfer.

- Illumination Compatibility: Proper lighting is crucial for line scan imaging. Factors such as LED versus halogen lighting, strobe synchronization, and light intensity must be considered.

- Environmental Conditions: Industrial settings may expose cameras to dust, vibrations, and temperature fluctuations, necessitating ruggedized designs.

By carefully evaluating these criteria, industries can optimize their inspection systems for maximum efficiency and accuracy.

Applications of Line Scan Cameras Across Industries

The versatility of line scan cameras allows them to be deployed across a broad range of industries where high-speed, high-resolution imaging is required:

- Manufacturing & Quality Control: Inspection of printed circuit boards, solar cells, silicon wafers, and flat panel displays to detect microscopic defects.

- Textile & Paper Industry: Monitoring of continuous rolls for imperfections such as tears, discoloration, or print misalignment.

- Automotive & Aerospace: Surface inspection of metals, composites, and vehicle components for structural integrity.

- Food & Beverage: High-speed sorting and quality analysis of fruits, vegetables, and packaged goods.

- Medical Diagnostics: Imaging of biological samples, histological slides, and pharmaceutical packaging integrity.

- Logistics & Postal Sorting: Tracking and sorting of barcoded items in distribution centers.

- Railway & Roadway Monitoring: Continuous imaging of railway tracks and road surfaces to detect wear and anomalies.

- Scientific & Satellite Imaging: High-resolution scanning of Earth’s surface for topographical mapping and remote sensing applications.

As industries demand faster, more accurate, and highly efficient inspection solutions, line scan cameras stand out as a superior imaging technology. Their ability to capture continuous, distortion-free images at high speeds makes them indispensable in modern manufacturing and quality control environments.

Intelgic’s cutting-edge vision technology and expertise in line scan camera solutions ensure unmatched precision, reliability, and efficiency for industrial inspection. Our innovative imaging solutions empower businesses with superior defect detection and process optimization.

For more information about how Intelgic can enhance your inspection processes, reach out to Intelgic today. Our team of experts is ready to assist you in finding the perfect vision solution tailored to your needs.