Why choosing right Lighting is important for Image Processing

Published on: Feb 19, 2025

Written by: Content team, Intelgic

Why choosing right Lighting is important for Image Processing

Lighting is a fundamental element in image processing applications, particularly in defect detection, measurement, and counting solutions. Proper lighting enhances image contrast, minimizes noise, and ensures accurate feature extraction, leading to precise and reliable results. Selecting the right lighting setup is crucial for achieving high-quality inspection and automation. This article explores the importance of lighting, various lighting techniques, the impact of different colors of lighting, and how Intelgic utilizes its expertise to provide optimized lighting solutions.

Importance of Lighting in Image Processing

Lighting significantly impacts the quality of captured images, influencing defect detection, object measurement, and counting accuracy. Inadequate lighting can obscure defects, introduce unwanted reflections, or lead to false positives and negatives. A well-designed lighting setup ensures that key features are clearly visible, allowing machine vision systems to function with high efficiency.

Choosing the Right Lighting

Selecting the appropriate lighting involves several critical factors, including:

- Object Material and Surface Characteristics: Reflective, matte, or transparent surfaces require distinct lighting approaches.

- Defect Type and Size: Micro-defects may require high-intensity illumination, while larger defects are best detected under diffused lighting.

- Environmental Conditions: Factors such as ambient light interference and varying working distances must be considered.

- Camera and Lens Compatibility: Lighting should align with camera specifications and field of view.

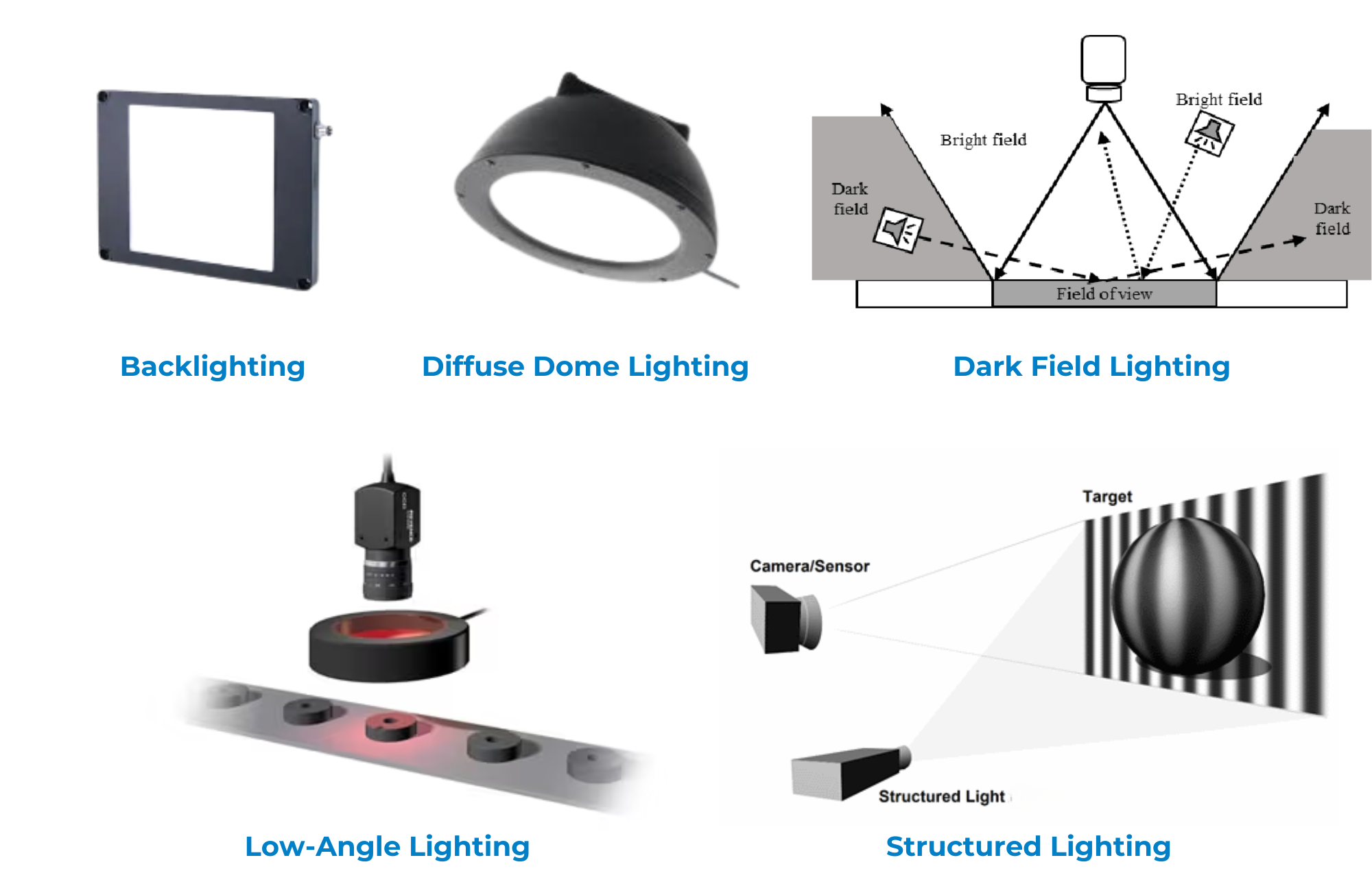

Different Angles of Lighting for Defect Detection, Measurement, and Counting

Various lighting angles are employed to highlight specific features and defects in image processing applications:

- Backlighting: Ideal for silhouette detection, dimensional measurement, and edge identification.

- Diffuse Dome Lighting: Reduces reflections and enhances contrast on glossy surfaces.

- Dark Field Lighting: Highlights surface scratches, cracks, and small defects by emphasizing scattered light.

- Low-Angle Lighting: Effective for detecting surface textures and fine defects.

- Structured Lighting: Uses patterned light to extract 3D surface data for precise measurement.

Role of Different Colors of Lighting

The color of the lighting source plays a crucial role in enhancing contrast, improving defect visibility, and ensuring accurate measurement and counting. Different colors interact uniquely with materials and surfaces, allowing for better defect identification:

- White Light: A general-purpose lighting option used for standard inspection across various applications, providing balanced contrast and clarity.

- Red Light: Minimizes chromatic aberrations in lenses and enhances contrast in certain materials, making it ideal for surface inspection and OCR applications.

- Blue Light: Shorter wavelength increases resolution and enhances the visibility of fine structures, commonly used for detecting small scratches and edges.

- Green Light: Frequently utilized for PCB inspection and measurement applications due to its ability to balance contrast and detail without excessive reflection.

- Infrared (IR) Light: Effective for detecting sub-surface defects, especially in materials with varying transparency. It is widely used in applications where visible light might cause glare or reflections.

- Ultraviolet (UV) Light: Detects fluorescence-based defects invisible under standard lighting, making it useful for surface contamination detection, security markings, and hidden crack identification.

Effective lighting is essential for achieving precision in image processing for defect detection, measurement, and counting. The right illumination enhances contrast, reduces noise, and improves accuracy, ensuring consistent and reliable inspection results across various industries. With extensive expertise in industrial machine vision solutions, Intelgic delivers tailored lighting setups to optimize automation and quality assurance. Contact Intelgic today to explore advanced lighting solutions to enhance your inspection accuracy and efficiency.