Why Automated Inspection Systems Are Essential for Assembly Verification

Published on: Jun 16, 2025

Written by: Content team, Intelgic

Introduction: The Manufacturing Quality Dilemma

In today’s highly competitive and fast-paced manufacturing environment, product quality and assembly accuracy are non-negotiable. Customers expect flawless products, regulatory bodies demand traceability, and internal stakeholders aim to reduce cost while maintaining high standards.

Traditional quality control methods — relying heavily on human inspectors — are inconsistent, error-prone, slow, and expensive in the long run. As product complexity increases and manufacturing volumes scale, manual inspection becomes a bottleneck.

This is where automated inspection systems using machine vision and AI come into play. These systems are revolutionizing how industries perform quality checks and assembly verification by delivering faster, more accurate, and fully traceable inspections.

What is an Automated Inspection System?

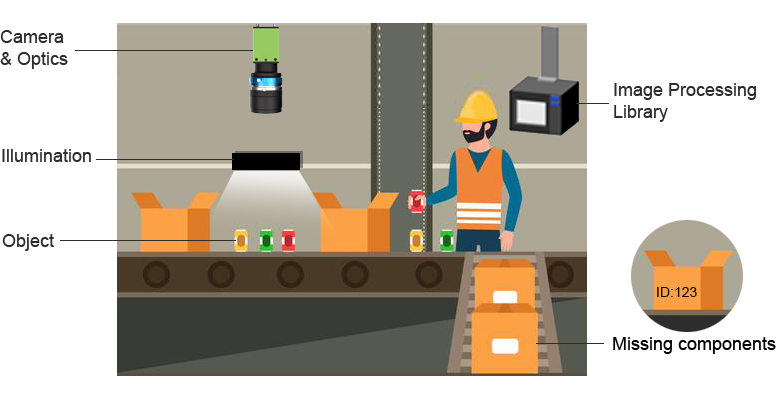

An automated inspection system is a combination of industrial cameras, specialized lighting, AI-powered software, and automated workflows that capture and analyze images of manufactured products or assemblies in real-time for defect detection, missing components and assembly errors. The automated inspection system is essential not only for detecting and capturing defects and rectifying them before shipping to customers, but also to keep track of what customers are receiving. This generate a complete inspection summary for any future reference and warranty validation.

These systems are typically deployed in:

- Quality Control (QC) stations to detect surface and dimensional defects

- Assembly lines to verify correct component placement and process adherence

- End-of-line inspections to ensure final product integrity before packaging

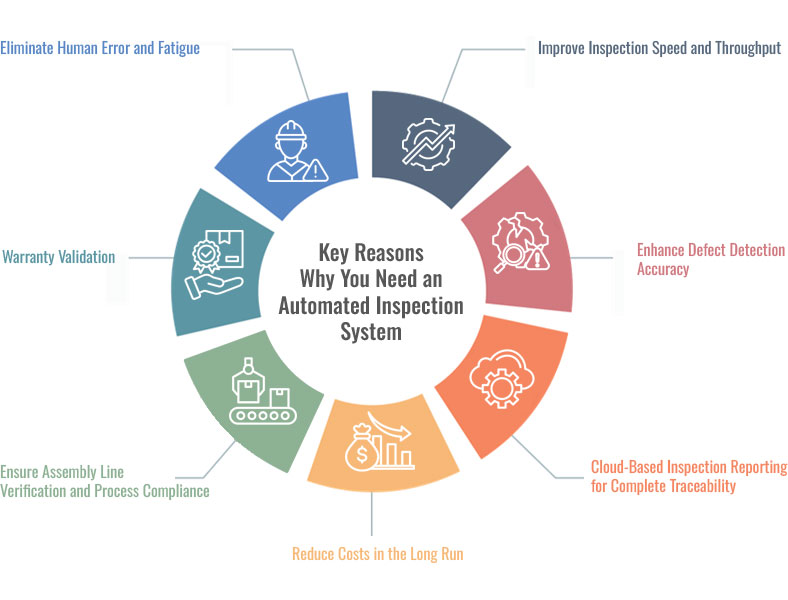

Key Reasons Why You Need an Automated Inspection System

Eliminate Human Error and Fatigue

Human inspectors can miss defects due to fatigue, distraction, or subjective judgment, especially during repetitive tasks. An AI-powered machine vision system:

- Works 24/7 without fatigue

- Maintains consistency across shifts and operators

- Uses objective criteria to detect even the smallest defects

This ensures that every product is inspected with the same high standard, reducing false passes and minimizing customer complaints.

Improve Inspection Speed and Throughput

Manual inspections are time-consuming and can slow down production. Automated systems:

- Inspect components in milliseconds

- Keep up with high-speed conveyor belts

- Enable 100% inspection rather than sampling

This leads to faster cycle times, better productivity, and shorter time-to-market without compromising quality.

Warranty Validation

In case of customer complaint and warranty claim, manufacturers can validate the complaint and what product was shipped to the customer.

- It keeps the video/image reports in the cloud

- Inspection Summary in the cloud.

- Full 360 degree view of the quality of the product in the production and assembly line.

Enhance Defect Detection Accuracy

Modern machine vision systems use high-resolution imaging, pixel-level analysis, and AI models trained on thousands of defect patterns. These systems can:

- Detect surface defects (scratches, cracks, contamination)

- Measure dimensions with sub-millimeter precision

- Identify defects invisible to the human eye

AI software continues to learn and improve with more data, ensuring that defect detection becomes smarter over time.

Ensure Assembly Line Verification and Process Compliance

One of the most overlooked causes of product failure is assembly errors — missing screws, incorrect wiring, improperly placed subcomponents, etc.

An automated system can:

- Monitor key assembly stages

- Verify presence, position, and orientation of parts

- Compare real-world assembly with digital templates or SOPs

- Trigger alerts for skipped steps or incorrect assembly patterns

This ensures process compliance and drastically reduces the risk of sending customers improperly assembled or incomplete products.

Cloud-Based Inspection Reporting for Complete Traceability

A major advantage of Intelgic’s automated inspection system is centralized cloud reporting — giving manufacturers unmatched visibility and control.

- For every product inspected, the system generates a summary report that includes:

- Defect classification and coordinates

- Annotated images and inspection data

- Pass/fail results linked to product serial or batch numbers

- Defect classification and coordinates

- These reports are stored in a secure cloud system, accessible anytime for audit, analysis, or validation.

Additionally, the system tracks assembly verification results in real-time. It logs:

- Component presence or absence

- Assembly completion checkpoints

- Operator errors or skipped steps

- Batch-wise assembly health reports

Result: Full Product Traceability

When a customer raises a complaint or warranty issue, manufacturers can immediately:

- Retrieve the product’s quality inspection summary

- Check assembly verification logs

- Verify that the product left the factory fully assembled and defect-free

This allows businesses to confidently respond to customer concerns, prove delivery quality, and identify areas for internal improvement if needed.

Reduce Costs in the Long Run

While automation requires upfront investment, the return on investment (ROI) is significant:

- Lower labor costs due to reduced reliance on human inspectors

- Reduced rework and scrap

- Fewer warranty claims and customer returns

- Enhanced brand reputation due to higher quality output

Many companies recoup their investment in automated inspection within 6–18 months depending on volume and complexity.

Enable Scalable and Flexible Quality Management

Automated systems are easy to scale as production grows or product designs change:

- Recipes and defect parameters can be updated through software

- AI models can be retrained with new product data

- Systems can be reconfigured for new product lines or inspection criteria

This makes them future-proof and ideal for dynamic manufacturing environments.

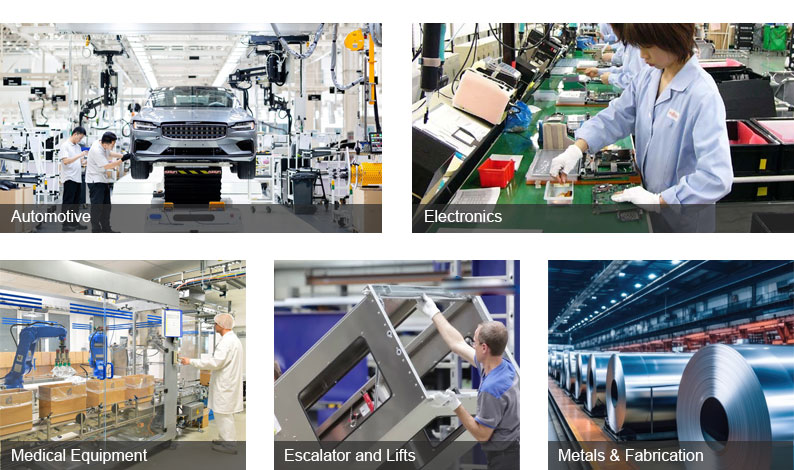

Industries

Almost every Industry needs an automated inspection system in their assembly process. The automated inspection not only checks for errors, it also saves the inspection summary within the software for future reference check to validate the warranty claim.

- Automotive: Verifying seat structures, customer facing parts, dashboards, components inside the bonnets, body parts, electronics, and powertrain components

- Electronics: Inspecting solder joints, PCB alignment, and chip placement, defects in the PCBs, counting of components within the PCB

- Medical Equipment: Visual defects and missing components within any machine or medical equipment. Verifying precise assembly and critical dimensions

- Escalator and Lifts: Missing components, improper installations with the controller, wrong part installation, visual defects.

- Metals & Fabrication: Surface defect detection on machined and rolled materials

Intelgic’s Advantage in Automated Inspection

Intelgic offers an all-in-one inspection platform with:

- Industrial-grade cameras and optics

- Advanced lighting techniques (ring, bar, dome, coaxial)

- Telecentric lenses for high-precision imaging

- AI inspection software with real-time detection, cloud reporting, and defect classification

- Assembly verification modules for SOP compliance monitoring

Whether it’s a standalone QC system or integrated inline inspection across your assembly floor, Intelgic enables full lifecycle quality assurance.

Conclusion: From Manual to Machine – The Future of Quality Control

In a world where quality equals reputation, automated inspection systems offer more than just defect detection — they provide confidence, accountability, and traceability.

With AI-powered vision systems, manufacturers gain the power to:

- Validate every product

- Prevent assembly defects

- Respond to customer complaints with evidence

- Improve processes continuously through data

Automation is not just about replacing humans — it’s about empowering manufacturers with insights, speed, and precision that manual methods simply cannot deliver.