What is Collimated Light and how its important in Machine Vision AI

Published on: Jun 02, 2025

Written by: Content team, Intelgic

What is Collimated Light and how its important in Machine Vision AI

In the world of optics and industrial measurement systems, collimated light serves as a cornerstone for achieving high accuracy and operational efficiency. While the term might sound highly technical or exclusive to optical engineers, its importance is growing across a wide range of industries. From manufacturing to quality control, the unique characteristics of collimated light make it indispensable in applications where precision, clarity, and consistency are non-negotiable. As production environments evolve to demand tighter tolerances and faster inspection speeds, the role of collimated light becomes not only relevant but essential to ensuring reliable and repeatable measurements.

What is Collimated Light?

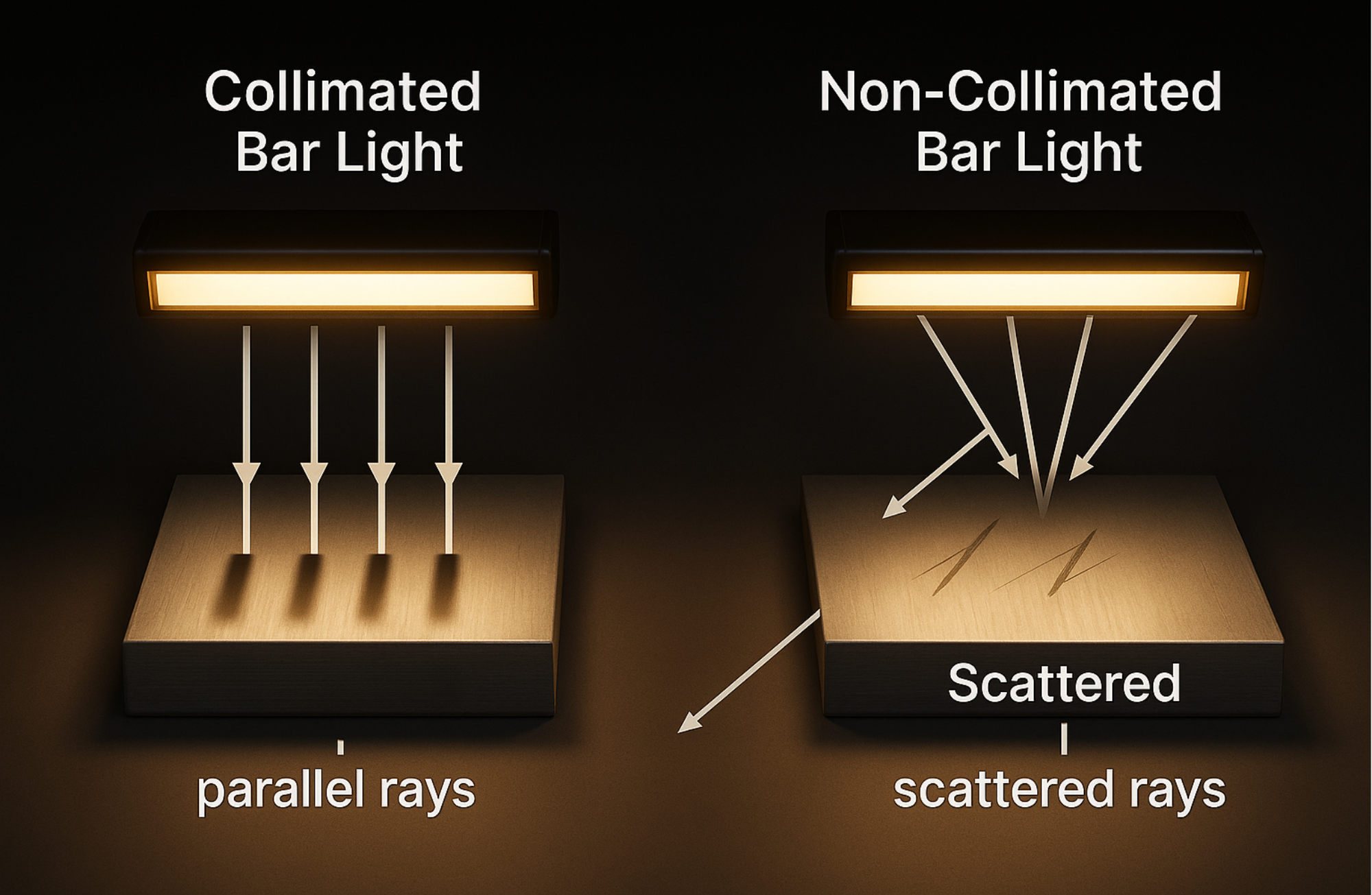

Collimated light refers to a beam of light whose rays travel in parallel, maintaining a consistent direction without diverging or converging significantly over a distance. In simpler terms, it’s a highly focused beam that doesn’t spread out as it moves away from the source. This property contrasts with ordinary light sources like bulbs or LEDs, which emit light that spreads in multiple directions.

Collimation can be achieved using lenses or mirrors to align light rays parallel to each other. The result is a narrow, uniform light beam that remains tight and coherent over long distances.

Why Use Collimated Light?

The primary advantage of collimated light lies in its ability to maintain a straight, narrow path over long distances. This makes it ideal for applications where optical precision and uniform illumination are essential.

Collimated light enhances performance in several key ways:

- Minimal Optical Distortion: Because the light rays remain parallel, collimated illumination significantly reduces scattering and lens-related distortion. This clarity is crucial for high-accuracy measurement, detection, and imaging applications.

- Sharp Shadow Edges: In backlit configurations, collimated light produces crisp silhouettes with well-defined boundaries. This is particularly useful when detecting edges, measuring object dimensions, or identifying small defects in profiles or contours.

- Consistent Intensity and Focus: The uniformity of collimated beams ensures even illumination across the target surface. This helps maintain consistent lighting conditions, which is critical for stable optical measurements and repeatable inspection results.

- High Measurement Precision: The non-diverging nature of the beam improves edge contrast and spatial accuracy, enabling precise dimensional analysis—even in high-speed or automated inspection environments.

Where Should We Use Collimated Light?

Collimated light is most effective in applications where precise edge detection, accurate dimensional analysis, or minimal optical distortion is required. It is especially useful in:

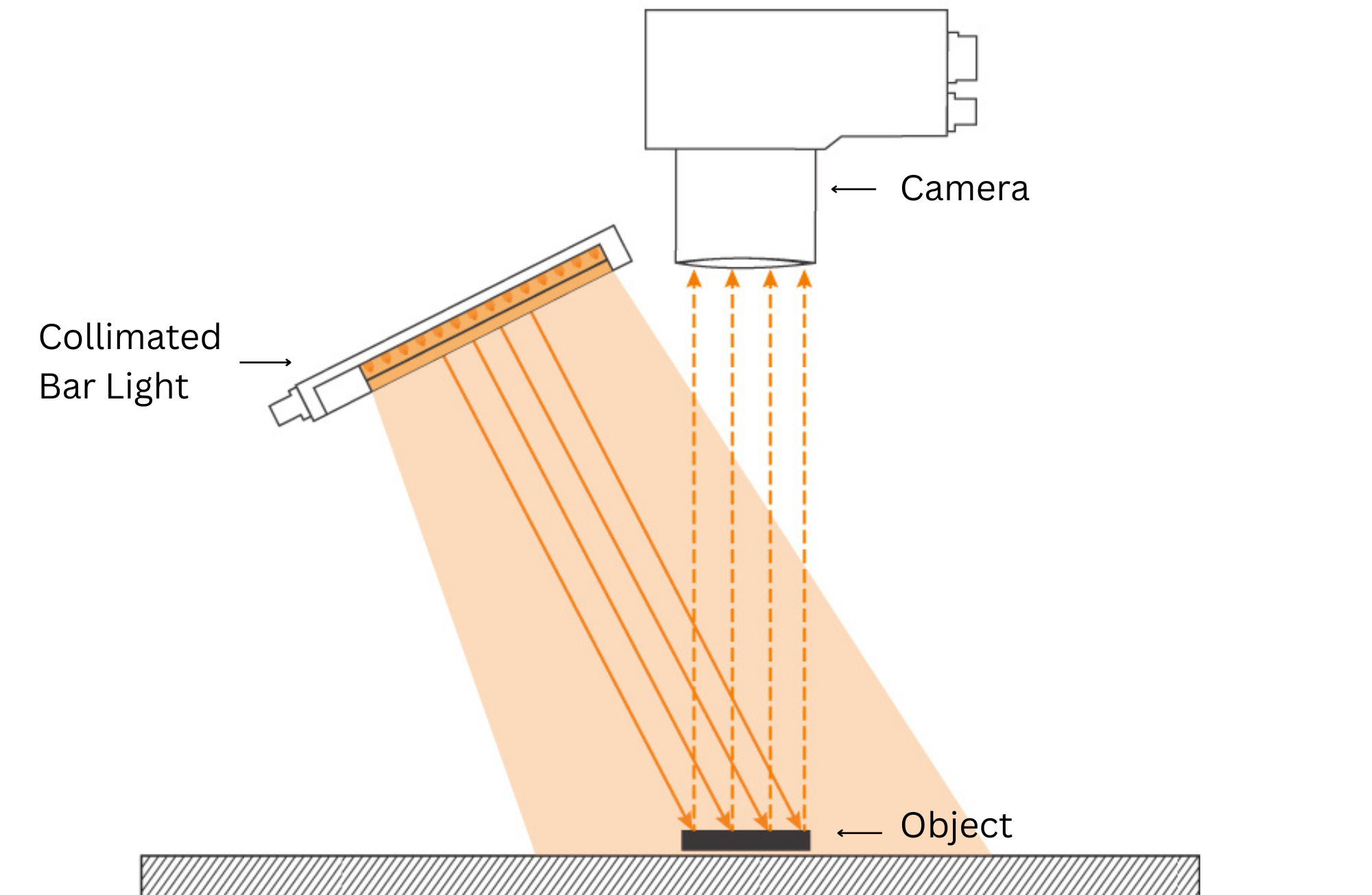

- Machine Vision Systems: For inspecting object contours, checking presence/absence of features, or detecting surface defects.

- Line Scan Imaging: Wide-format collimated lights are ideal for inspecting long-length and wide sheets. Their uniform, directional illumination ensures consistent backlighting across moving materials, enabling accurate edge detection and dimensional measurement in real-time line scan imaging systems.

- Laser Profiling and Triangulation: To measure heights, profiles, or thicknesses using structured light.

- Metrology and Coordinate Measuring Machines (CMMs): Where any beam spread could introduce error in measuring tight tolerances.

- PCB and Flat Panel Inspection: For verifying alignment, cuts, slots, or warping in electronic and glass components.

- Transparent or Reflective Surface Inspection: Where glare and internal reflection must be minimized for accurate analysis.

Industrial Use Case: Accurate Dimensional Measurement

In industries such as metal fabrication and woodworking, the accurate measurement of cut-to-length metal sheets and long, wide wooden panels is critical for maintaining product quality, reducing material waste, and ensuring compatibility with downstream processes.

Collimated light plays an essential role in these applications by delivering a uniform, parallel beam of illumination that creates sharp, high-contrast edges. When positioned in a backlighting configuration, collimated light allows vision systems or optical sensors to clearly distinguish the boundaries of large, flat materials—even at high conveyor speeds.

For metal sheets, this ensures precise detection of width, length, and squareness, which is vital for applications requiring tight dimensional tolerances. In the case of wooden panels, particularly those used in flooring, furniture, or construction, collimated lighting helps identify edge deviations, warping, or dimensional inconsistencies that might affect fit or finish.

By providing non-contact, high-accuracy edge detection, collimated light enables real-time quality control across a range of materials and industries. Whether dealing with reflective metal surfaces or textured wooden panels, this lighting approach supports consistent, reliable measurement—even across wide and long-format materials.

Collimated light is a cornerstone of modern optical measurement systems, especially in industries where dimensional accuracy and precision are critical. Its unique properties—parallel beam paths, minimal divergence, and uniform intensity—make it essential for a wide range of applications, from edge detection to inline inspection in high-speed production environments.

At Intelgic, we leverage this advanced lighting technology to develop automated, vision-based solutions that deliver precise, real-time measurement and quality control. Our expertise in integrating collimated lighting into industrial inspection systems ensures that manufacturers can achieve greater accuracy, consistency, and operational efficiency across a variety of materials and use cases.

As manufacturing continues to evolve toward higher automation and tighter tolerances, Intelgic’s solutions using collimated light will remain at the forefront—enabling smarter, faster, and more reliable production processes.