Sunglass Inspection- Ensuring Optical Quality and Aesthetic Perfection

Published on: Sep 29, 2025

Written by: Content team, Intelgic

Sunglasses are not just fashion accessories—they are precision optical products designed to protect the eyes from harmful UV radiation, glare, and intense light. Consumers expect both flawless visual performance and aesthetic perfection in every pair. For manufacturers, this means rigorous inspection at multiple stages of production to detect any visual, structural, or cosmetic defects. Traditional manual inspection, relying on human eyes, is time-consuming and prone to subjectivity. Today, machine vision and AI-based sunglass inspection systems are setting new standards for speed, consistency, and accuracy.

Key Challenges in Sunglass Inspection

Unlike flat or uniform optical components, sunglasses present unique inspection challenges:

- Curved and tinted lenses – variable reflectivity and optical distortion make defect detection difficult.

- Polarized and coated surfaces – scratches, peeling, or uneven coating require specialized illumination angles.

- Frames of diverse shapes and colors – inspection must adapt to different geometries and textures.

- Aesthetic and branding elements – logos, engravings, and design features must be verified without misinterpretation.

- Dual components (lens + frame) – both must be inspected together for alignment, fit, and symmetry.

Types of Defects in Sunglasses

Inspection systems need to detect both functional defects (that affect performance) and cosmetic defects (that impact consumer acceptance):

Lens Defects

- Scratches, cracks, and abrasions

- Air bubbles or inclusions in lens material

- Uneven or peeling anti-reflective/polarized coatings

- Incorrect tint, shading, or gradient uniformity

- Warping or optical distortion

Frame Defects

- Surface scratches, dents, or discoloration

- Molding defects such as burrs or flash

- Misalignment of arms/temples

- Loose hinges or improper assembly

- Logo misplacement or poor engraving/printing

Automated Sunglass Inspection with Machine Vision & AI

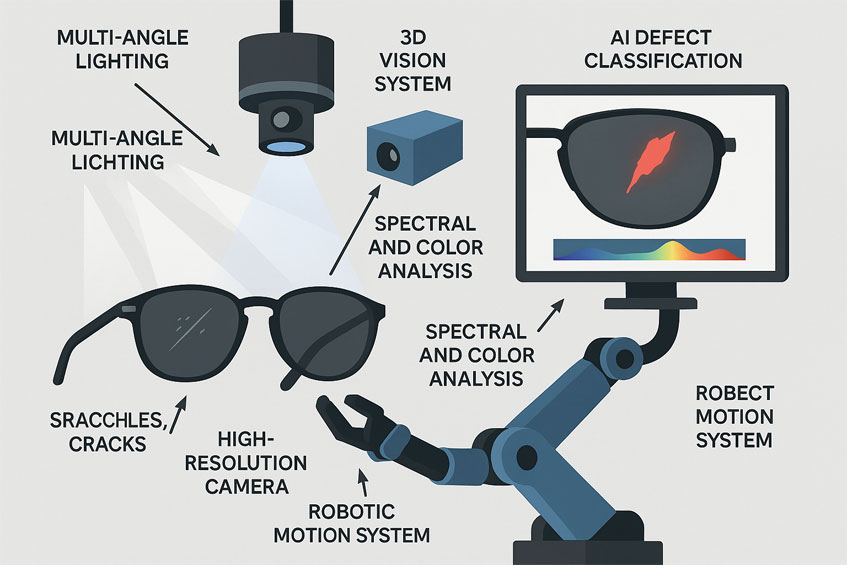

Modern sunglass inspection uses high-resolution imaging and AI software to detect even the tiniest flaws. Key technologies include:

- Multi-angle lighting – dark-field, coaxial, and polarized illumination reveal scratches, coating defects, and distortions.

- 3D vision systems – verify frame geometry, curvature, and hinge alignment.

- Spectral and color analysis – ensure accurate tint, gradient, and polarization levels.

- Robotic motion systems – adjust camera and light positions to cover curved surfaces consistently.

- AI defect classification – differentiates true defects from reflections, dust, or acceptable natural variations.

Benefits of Automated Sunglass Inspection

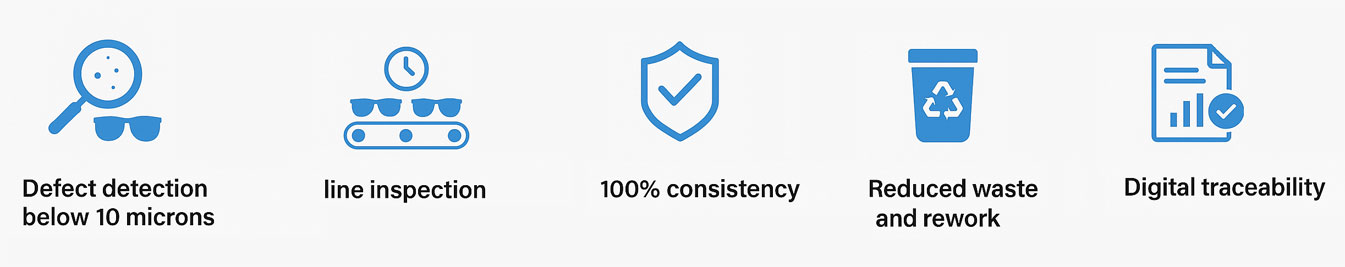

- Defect detection below 10 microns – ensuring invisible scratches don’t compromise performance.

- Inline inspection – quality checks without slowing down manufacturing speed.

- 100% consistency – eliminating subjectivity of human inspection.

- Reduced waste and rework – early defect detection prevents defective products from reaching packaging.

- Digital traceability – each batch or model can be linked to inspection reports and defect statistics.

Intelgic’s Sunglass Inspection System

Intelgic offers a complete turnkey sunglass inspection solution combining advanced optics, robotic imaging, and AI-powered defect detection software.

Our system includes:

- Specialized lighting modules to detect micro scratches, coating issues, and uneven tints.

- High-resolution area scan cameras with telecentric optics for distortion-free imaging.

- Robotic motion system for lens curvature coverage and frame alignment inspection.

- Live Vision AI software for real-time defect detection, classification, and reporting.

- Digital Quality Certificate (DQC) for each inspected batch, enabling full compliance and traceability.

By integrating seamlessly into manufacturing lines, Intelgic enables sunglass manufacturers to achieve zero-defect quality while maintaining high throughput and consumer confidence.

In today’s competitive eyewear market, quality is inseparable from brand reputation. Automated sunglass inspection systems provide manufacturers with the tools to ensure every pair of sunglasses meets the highest standards of optical performance, durability, and aesthetics. With Intelgic’s AI-driven inspection technology, manufacturers can scale production while delivering flawless eyewear that consumers trust.