Stitching Defect Detection Using Machine Vision Ai

Published on: Dec 31, 2024

Written by: Content team, Intelgic

Stitching Defect Detection Using Machine Vision AI

In industries such as automotive, textiles, footwear, furniture, and apparel, stitching quality plays a critical role in ensuring both functionality and aesthetic appeal. Defects in stitching, such as skipped stitches, loose threads, misaligned patterns, or inconsistent spacing, can lead to compromised product quality and customer dissatisfaction. Detecting these defects manually is labor-intensive, time-consuming, and prone to human error, especially in high-volume production environments.

Machine Vision AI offers a highly efficient and accurate solution for detecting stitching defects. By leveraging high-resolution imaging, advanced lighting, and AI-powered analysis, manufacturers can automate the inspection process, ensuring consistent quality and minimizing production costs.

Common Stitching Defects

Stitching defects vary across industries and materials but generally include:

- Skipped Stitches:

- Missing stitches in the seam caused by malfunctioning needles or improper tension.

- Loose Threads:

- Threads that are not properly cut or secured, leading to potential unraveling.

- Uneven Spacing:

- Inconsistent distances between stitches, compromising the seam's strength or appearance.

- Broken Stitches:

- Fractured threads caused by needle damage, improper tension, or material resistance.

- Misaligned Patterns:

- Stitch lines that deviate from the intended design, often caused by material misalignment.

- Overlaps and Overstitches:

- Excessive or redundant stitching leading to thicker or uneven seams.

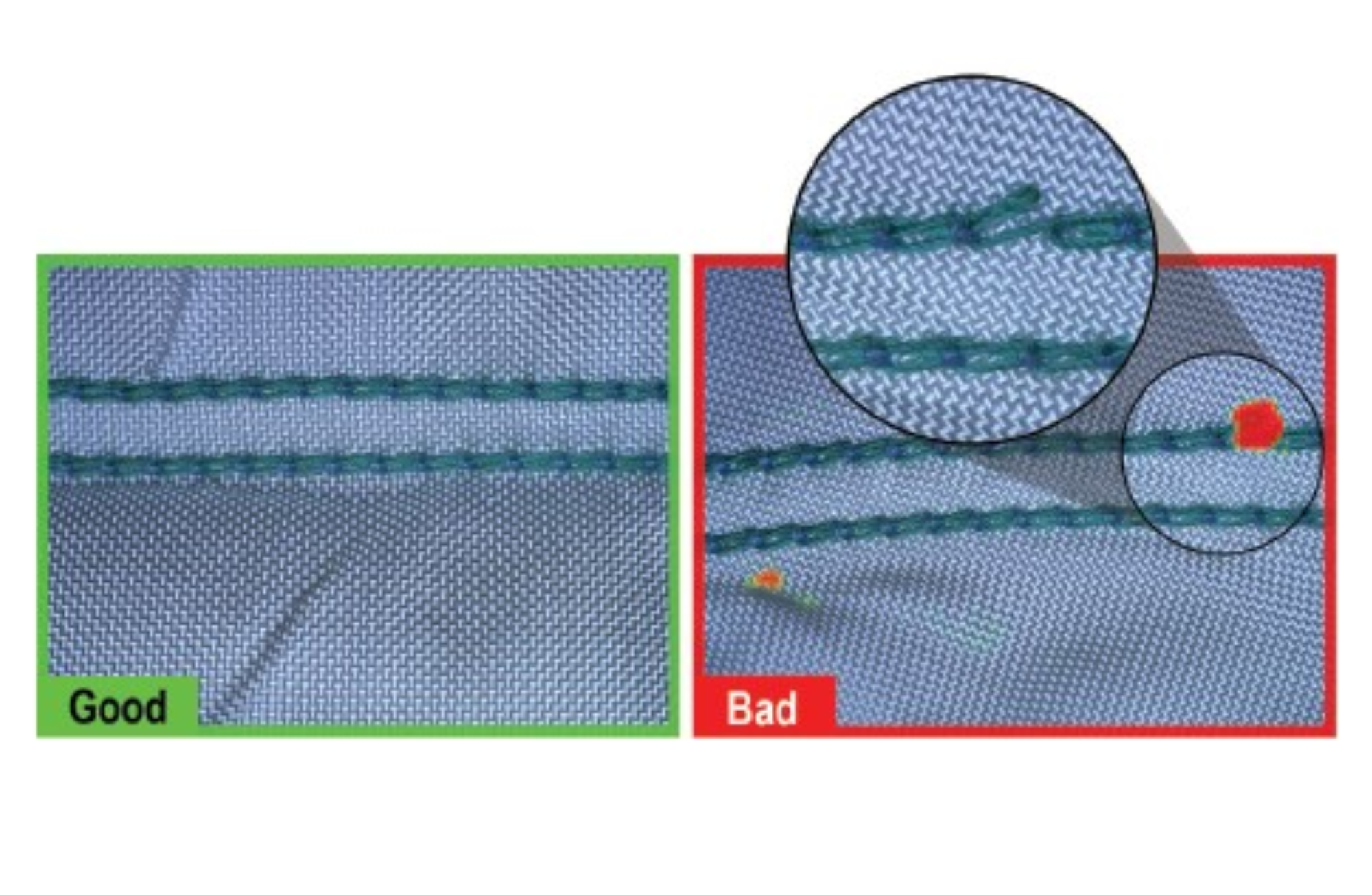

- Contamination or Stains:

- Foreign particles, oil stains, or discoloration affecting the stitching area.

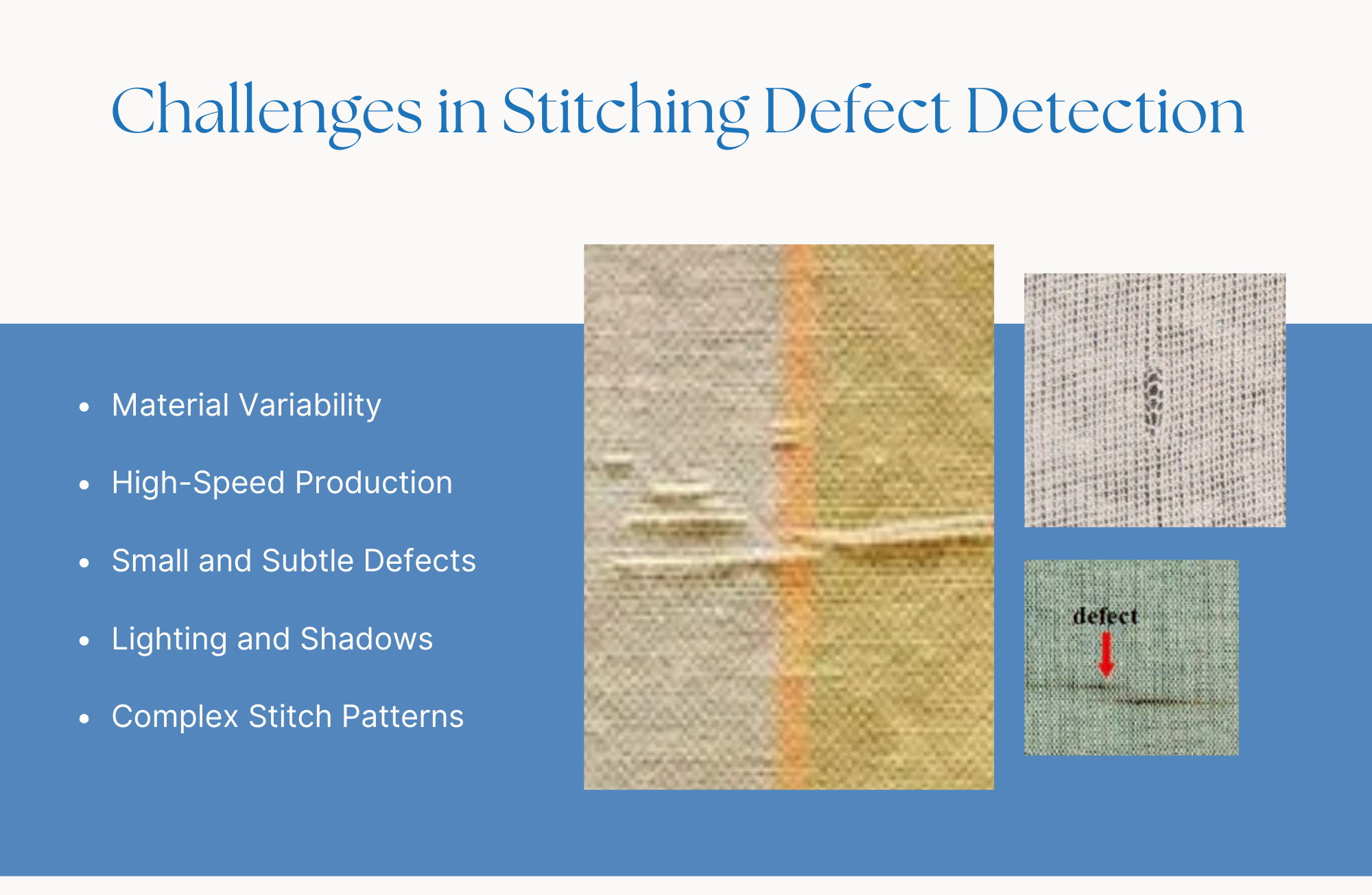

Challenges in Stitching Defect Detection

- Material Variability:

- Different textures, colors, and patterns in materials can make defect detection complex.

- High-Speed Production:

- In fast-paced manufacturing, stitching defects must be detected in real-time to avoid delays.

- Small and Subtle Defects:

- Fine stitches or minor inconsistencies are difficult to spot visually.

- Lighting and Shadows:

- Poor or uneven lighting can obscure defects or create artifacts that mimic defects.

- Complex Stitch Patterns:

- Decorative or intricate stitching designs add complexity to defect detection.

How Machine Vision AI Detects Stitching Defects

Machine Vision AI integrates advanced imaging systems, lighting solutions, and AI algorithms to analyze stitching quality with precision and efficiency.

1. High-Resolution Imaging

- Camera Selection:

- High-resolution cameras capture fine details of stitches, enabling the detection of small defects.

- Multi-Camera Systems:

- Multiple cameras positioned at different angles ensure comprehensive coverage of complex seams.

2. Advanced Lighting Solutions

Proper lighting is crucial for highlighting stitching defects without introducing glare or shadows.

- Diffuse Lighting:

- Provides even illumination, reducing shadows and reflections for consistent imaging.

- Directional Lighting:

- Enhances visibility of surface irregularities such as loose threads or broken stitches.

- Backlighting:

- Highlights contour defects like uneven spacing or overlaps.

3. AI-Powered Image Analysis

AI algorithms analyze captured images to detect, classify, and report stitching defects.

- Pattern Recognition:

- AI identifies normal stitching patterns and flags deviations such as skipped or misaligned stitches.

- Edge Detection:

- Analyzes stitch edges to detect breaks, overlaps, or irregular spacing.

- Color and Texture Analysis:

- Differentiates between stitching threads and background materials for precise defect identification.

- Real-Time Processing:

- Detects defects instantly, enabling immediate corrective actions in high-speed production lines.

4. Defect Classification

AI systems classify defects based on severity, type, and location, providing actionable insights for quality control.

- Severity Grading:

- Classifies defects as critical, major, or minor, prioritizing repairs accordingly.

- Location Mapping:

- Pinpoints the exact location of defects for targeted rework or adjustment.

5. Data Logging and Reporting

Inspection results are logged and analyzed for process optimization.

- Trend Analysis:

- Identifies recurring defects to address root causes.

- Production Metrics:

- Tracks stitching quality performance over time for continuous improvement.

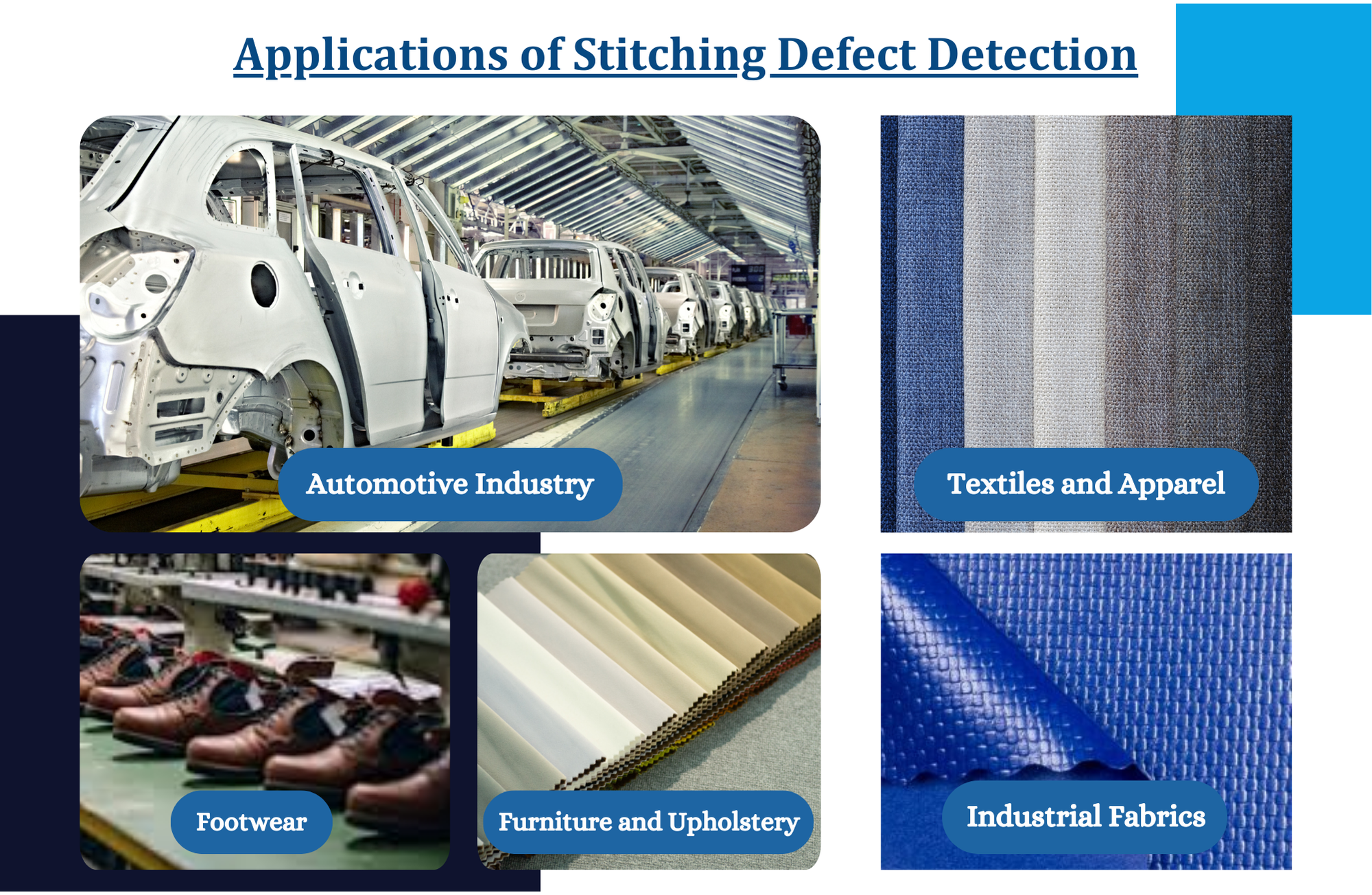

Applications of Stitching Defect Detection

1. Automotive Industry

- Inspecting stitching on car seats, steering wheels, and interior panels for uniformity and durability.

2. Textiles and Apparel

- Detecting defects in garments, home textiles, and decorative stitching to ensure quality and aesthetics.

3. Footwear

- Inspecting stitching on shoes, boots, and leather products to ensure structural integrity and visual appeal.

4. Furniture and Upholstery

- Ensuring high-quality stitching in sofas, chairs, and cushions for strength and appearance.

5. Industrial Fabrics

- Monitoring stitching in conveyor belts, safety harnesses, and tarpaulins for reliability and safety compliance.

Advantages of Machine Vision AI for Stitching Inspection

- High Accuracy:

- Detects even the smallest defects, ensuring consistent quality.

- Real-Time Analysis:

- Provides immediate feedback, minimizing downtime and reducing waste.

- Scalability:

- Adapts to different materials, stitch types, and production speeds.

- Cost Efficiency:

- Reduces labor costs by automating repetitive inspection tasks.

- Objective and Consistent:

- Eliminates variability in manual inspections, ensuring reliable results.

Implementing Machine Vision AI for Stitching Inspection

1. System Design

- Analyze production requirements to select suitable cameras, lighting, and AI algorithms.

2. Calibration and Training

- Calibrate the system for the specific material, stitch type, and defect criteria.

- Train AI models using diverse datasets to improve detection accuracy.

3. Integration with Production Line

- Integrate the vision system with existing machinery for seamless operation.

- Use sensors to trigger imaging at precise intervals based on stitching progress.

4. Continuous Optimization

- Monitor system performance and update AI models as production requirements evolve.

Intelgic’s Expertise in Stitching Defect Detection

At Intelgic, we specialize in designing and deploying AI-powered Machine Vision systems for stitching defect detection. Our solutions combine advanced imaging technologies, custom AI algorithms, and robust hardware to deliver precise and reliable quality control.

Why Choose Intelgic?

- Tailored Solutions:

- Systems designed to meet the specific needs of your stitching process and material types.

- Advanced AI Algorithms:

- Trained to handle complex stitch patterns and diverse defect types.

- Real-Time Feedback:

- Enables immediate corrective actions, reducing downtime and waste.

- Comprehensive Support:

- From consultation to implementation and maintenance, we ensure seamless integration and operation.

Stitching defect detection is a critical component of quality control in industries where stitching plays a vital role in product functionality and aesthetics. Machine Vision AI offers a powerful solution for automating this process, ensuring consistent quality, reducing costs, and enhancing operational efficiency.

Intelgic’s cutting-edge solutions provide unparalleled accuracy and reliability, empowering manufacturers to meet the highest quality standards. Contact Intelgic today to learn how our systems can revolutionize your stitching inspection processes.