Steel Oil Drum Inspection with Machine Vision AOI for Precise Quality Control in Chakpachuria

Published on: May 21, 2025

Written by: Content team, Intelgic

Steel Oil Drum Inspection with Machine Vision AOI for Precise Quality Control

Steel oil drums serve as essential containers across diverse industries, including petrochemicals, lubricants, and food processing. Maintaining their structural integrity and surface quality is paramount to ensuring safety, regulatory compliance, and customer satisfaction. Conventional inspection methods, predominantly based on manual visual examination, are often prone to inconsistency and inefficiency. In contrast, Automated Optical Inspection (AOI) leveraging advanced Machine Vision technology offers a state-of-the-art solution, delivering precise, rapid, and highly repeatable defect detection for steel oil drums.

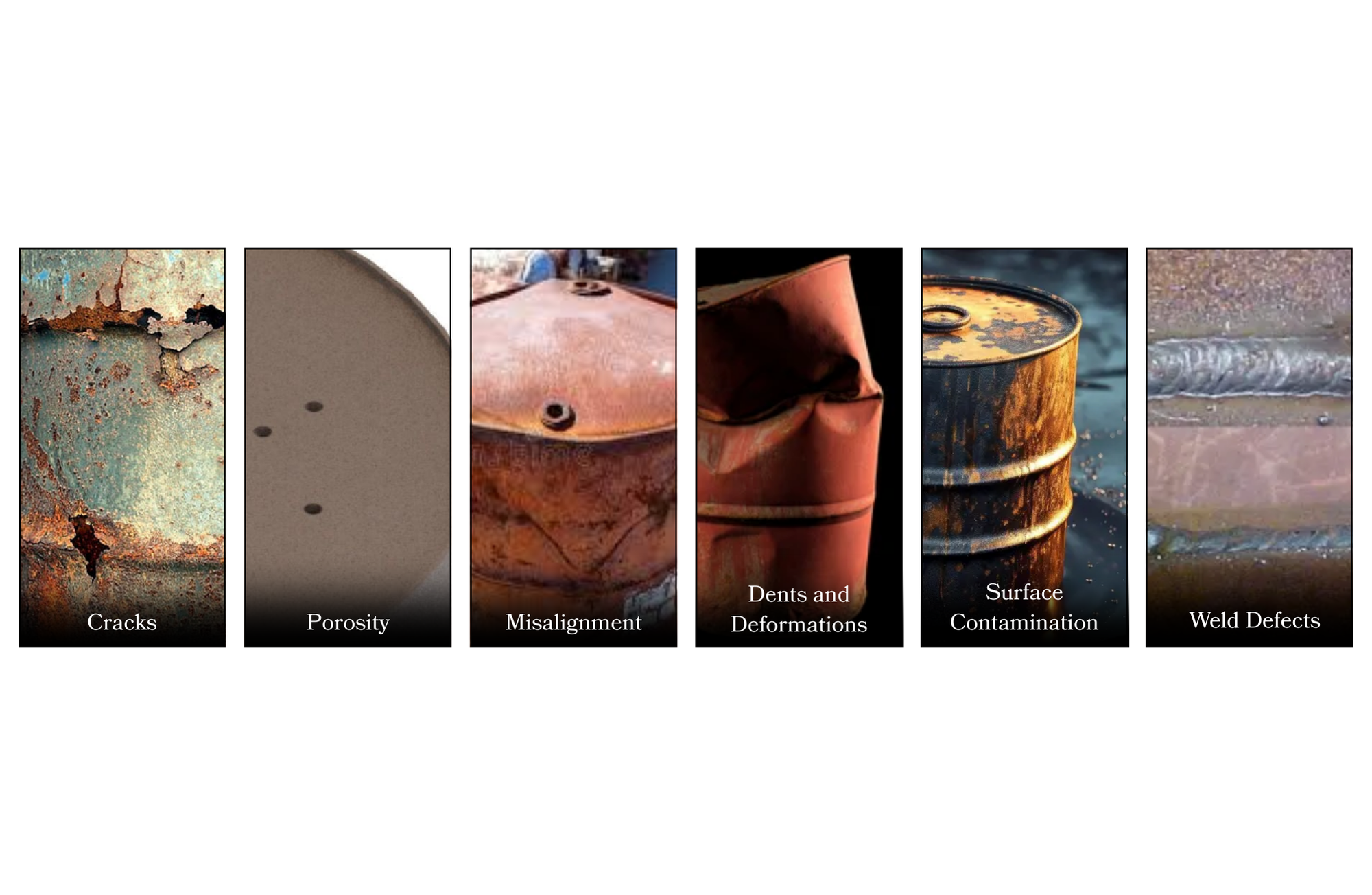

Common Defects in Steel Oil Drums

Steel oil drums can exhibit a variety of defects, which may compromise their performance and safety:

- Cracks: Micro-cracks or surface cracks can lead to leaks or structural failure.

- Porosity: Tiny holes or pores in the steel that can weaken the drum’s integrity.

- Misalignment: Incorrect alignment of drum components such as lids and seams, leading to sealing problems.

- Dents and Deformations: Physical damage impacting shape and strength.

- Surface Contamination: Presence of dirt, oil stains, or rust affecting quality.

- Weld Defects: Incomplete or weak welds compromising durability.

Inspection Challenges and Risks

- Detection of Subtle Defects: Minor cracks, porosity, misalignment, and potential leakage points are challenging to identify with the naked eye or conventional imaging techniques.

- High Inspection Speed Requirements: Production lines often operate at rapid speeds, requiring real-time, non-intrusive inspection capable of detecting defects including leaks without interrupting workflow.

- Environmental Factors: Variations in lighting conditions, dust accumulation, and reflective metallic surfaces can obscure defects such as cracks, porosity, and leakage, complicating accurate detection.

- Consistency and Accuracy: Human inspectors are susceptible to fatigue and subjective judgment, which can lead to inconsistent detection of critical defects including micro-leaks.

- Data Handling and Traceability: The system must efficiently process and securely store large volumes of inspection data, including detailed records of detected defects and leakage incidents, to ensure comprehensive quality traceability.

How Machine Vision AOI Overcomes Inspection Challenges

Machine Vision AOI systems designed specifically for steel oil drum inspection leverage advanced hardware and AI-powered software to mitigate these challenges effectively:

High-Resolution Machine Vision Camera

- Utilizes a high-resolution area scan camera with a pixel size of around 3.5 micrometers, capable of capturing minute defects such as micro-cracks and porosity.

- The camera uses a GigE interface for fast, reliable data transmission, minimizing inspection latency and ensuring seamless integration into high-speed production lines.

Specialized Lighting System

A customized, adjustable lighting setup is employed to enhance the visibility of subtle defects such as cracks, porosity, misalignment, and leakage. The system integrates multiple illumination techniques:

- Coaxial Lighting: Delivers shadow-free, uniform light ideal for detecting surface flaws like cracks and corrosion on reflective steel surfaces.

- Structured Lighting: Projects grids or lines to detect deformations, dents, and misalignments by highlighting surface irregularities.

- Backlighting: Used to inspect edges, seams, and potential leakage points by creating high-contrast silhouettes of openings or misalignments.

Customized Mounting Options for Drum Inspection

The system offers two tailored configurations to suit different inspection needs:

- Robotic Arm Integration: A customized robotic arm provides 360-degree coverage of the steel oil drum, enabling comprehensive inspection from all angles. This automated movement ensures no surface area is missed, making it ideal for high-precision and dynamic inspection environments.

- Adjustable Mounting Stands: For stationary setups, adjustable stands allow precise positioning of the camera and lighting systems. They ensure the correct working distance and optimal lighting angles for capturing detailed images on curved, reflective drum surfaces.

AI-Powered Software

At the heart of the system is an advanced AI model trained on diverse steel oil drum images to detect defects such as cracks, porosity, misalignment, and leakage. It classifies each drum as “OK” or “Not OK” with high accuracy.

The model continuously improves through retraining with new data, reducing false positives and enhancing defect recognition—even for subtle or previously unseen issues.

Its flexible architecture supports easy integration of new defect types, making the solution fully scalable and future-proof as quality standards evolve.

Benefits of Machine Vision AOI for Steel Oil Drum Inspection

- Enhanced Defect Detection: Detects micro-level defects with high precision, improving overall product quality.

- Increased Throughput: Enables rapid, automated inspection inline with production speeds.

- Reduced Human Error: Offers objective and consistent quality assessment.

- Cost Savings: Minimizes scrap, rework, and warranty claims by early defect detection.

- Data-Driven Quality Control: Facilitates better traceability and continuous process improvement.

Intelgic: Pioneering Excellence in Machine Vision Inspection

Intelgic sets itself apart through its deep expertise and end-to-end approach to machine vision for steel oil drum inspection:

- End-to-End Customization: Every component—from lighting systems to fixture engineering—is tailored to match the client’s specific drum types and production workflows.

- Advanced AI Integration: Proprietary AI models trained on large, diverse datasets ensure accurate defect detection with minimal false positives.

- Industrial-Grade Reliability: High-resolution GigE cameras and durable enclosures deliver consistent performance in demanding industrial environments.

- User-Centric Design: Intuitive interfaces and plug-and-play integration simplify operation, reducing setup time and training needs.

- Scalability and Ongoing Support: Intelgic’s modular architecture and continuous AI updates ensure the system evolves with changing inspection requirements.

The inspection of steel oil drums is essential for ensuring safety and quality across various industries. Traditional manual inspection methods can no longer keep up with the rigorous standards and fast pace of modern manufacturing. Machine Vision AOI systems—integrating high-resolution imaging, specialized lighting, and AI-driven analysis—offer an efficient, reliable, and scalable solution to detect subtle defects like cracks, porosity, and misalignment.

With its comprehensive, customized approach and advanced technology, Intelgic delivers superior machine vision solutions that revolutionize steel oil drum inspection—enhancing productivity, minimizing risk, and elevating product quality.

Contact Intelgic Today to discover how our innovative solutions can safeguard your production and ensure impeccable quality.