Spectacle Lens Inspection for Visual Defect Detection

Published on: Sep 29, 2025

Written by: Content team, Intelgic

Detect Defects in glasses and lenses

Spectacle lenses are precision optical products where even the smallest defect can compromise visual clarity, patient comfort, and long-term performance. Manufacturers of ophthalmic and spectacle lenses must ensure that every lens meets strict quality standards before reaching consumers. Manual inspection using microscopes or the naked eye is no longer sufficient due to increasing production volumes and the demand for near-zero defect quality. Automated lens inspection systems powered by machine vision and AI are now transforming how visual defects are detected in spectacle lens manufacturing.

Challenges in Spectacle Lens Inspection

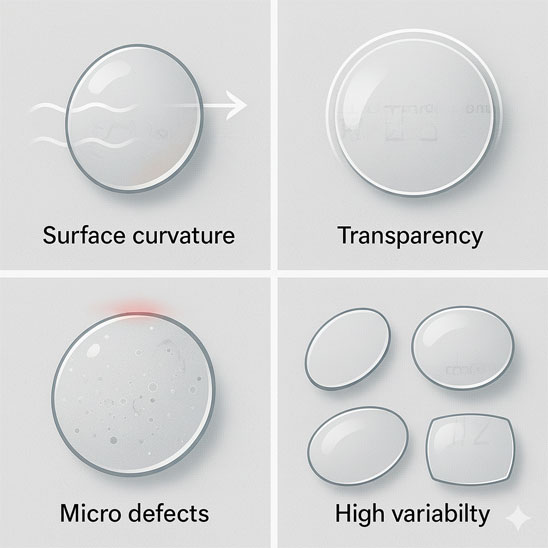

Unlike flat glass, spectacle lenses are transparent, curved, and highly reflective surfaces. This presents unique inspection challenges:

-

Surface curvature – causes irregular light reflection and distortion, requiring dynamic lighting control.

-

Transparency – defects such as scratches or inclusions are often invisible under normal illumination.

-

Micro defects – tiny scratches, bubbles, and coating inconsistencies may be smaller than 10 microns but can affect optical clarity.

-

High variability – lenses differ in size, thickness, refractive index, and coatings, making a one-size-fits-all solution ineffective.

Types of Defects in Spectacle Lenses

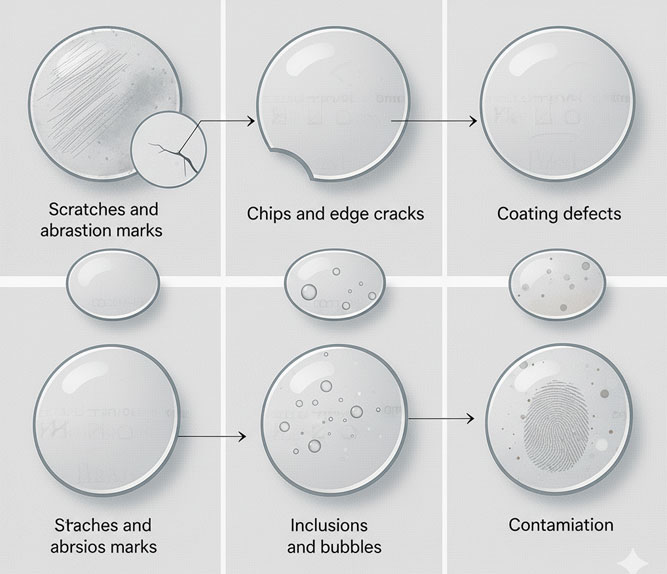

Some of the most common visual defects include:

-

Scratches and abrasion marks – caused during grinding, polishing, or handling.

-

Chips and edge cracks – arising from cutting and edging processes.

-

Inclusions and bubbles – formed during lens casting or molding.

-

Coating defects – anti-reflective, hydrophobic, or scratch-resistant coatings may have uneven layers, peeling, or spots.

-

Contamination – dust particles, fingerprints, or chemical residues that reduce clarity.

Automated Machine Vision for Lens Inspection

Modern automated inspection systems combine high-resolution cameras, telecentric or zoom lenses, and specialized lighting geometries to capture detailed images of the lens surface. These images are processed by AI-driven defect detection software, which identifies and classifies defects in real-time.

Key technologies used include:

- Telecentric imaging for distortion-free edge and surface inspection.

- Dark-field and coaxial lighting to highlight surface scratches and micro cracks.

- Multi-angle illumination for detecting coating uniformity.

- AI-based defect detection that distinguishes true defects from reflections or dust.

Benefits of Automated Lens Inspection

- High accuracy – detection of micro-defects below 10 microns.

- Consistency – eliminates human subjectivity in inspection.

- Speed – inline inspection at production speed without slowing down throughput.

- Traceability – inspection results linked to batch and lens ID for quality records.

- Cost savings – reduced rework, returns, and warranty claims.

Intelgic’s Spectacle Lens Inspection Solution

Intelgic provides end-to-end automated lens inspection systems tailored for spectacle lens manufacturers. Our solution includes:

- Robotic motion system to adjust cameras and lights according to lens curvature.

- Specialized optics for high-resolution imaging of transparent and coated surfaces.

- Adaptive lighting control to detect defects under varying refractive conditions.

- Live Vision AI software that automatically detects, classifies, and reports defects.

- Digital Quality Certificates (DQC) generated for every inspected lens, ensuring compliance and traceability.

Intelgic’s turnkey systems integrate seamlessly into existing manufacturing lines, helping manufacturers deliver flawless optical quality at scale.

With rising consumer expectations and stringent quality standards, automated spectacle lens inspection has become essential in the ophthalmic industry. By leveraging advanced optics, robotic systems, and AI-based defect detection, manufacturers can ensure every lens that reaches the market offers perfect clarity and durability. Companies like Intelgic are at the forefront of this transformation, enabling lens makers to achieve zero-defect manufacturing while maintaining productivity and efficiency.