Small Part Recognition Using Dimension and Size – Powered by Intelgic Vision AI

Published on: Oct 03, 2025

Written by: Content team, Intelgic

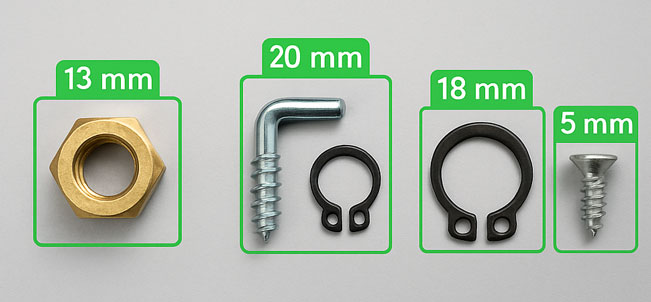

In modern manufacturing, accurate part recognition and classification play a crucial role in ensuring product quality, traceability, and assembly line efficiency. Small components—such as pins, screws, nuts, washers, and micro-mechanical parts—may look similar to the human eye, but even the slightest variation in diameter, dimension, or visual features can have a significant impact on product performance. Manual recognition is slow and error-prone, while traditional inspection methods often lack flexibility for complex and high-volume operations.

Intelgic’s Vision AI–Based Small Part Recognition System

Intelgic provides an advanced machine vision and AI-based solution to automatically recognize and classify small parts based on size, dimension, and measurement specifications. Using high-resolution cameras, specialized optics, and AI-driven software, the system accurately detects the subtle differences between similar-looking parts in real time.

Key capabilities include

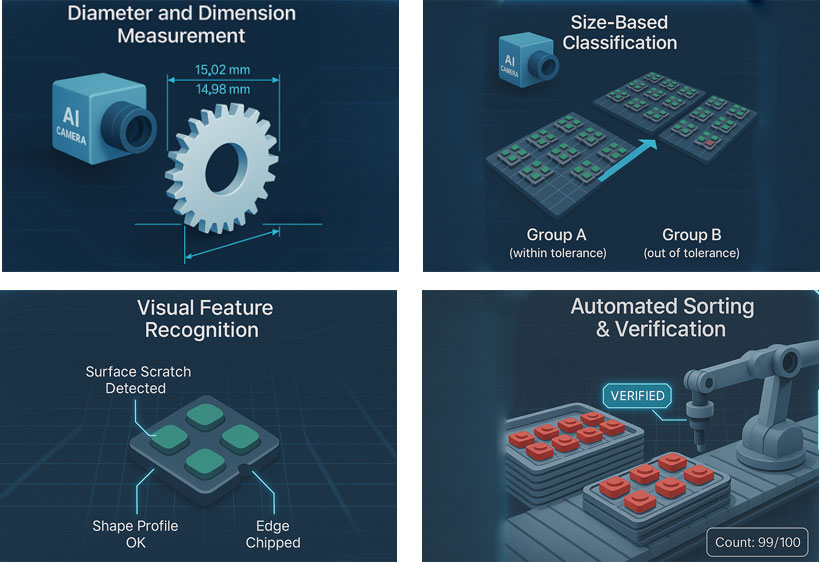

Diameter & Dimension Measurement

The system measures outer diameter, inner diameter, length, width, and thickness with micron-level accuracy.

Size-Based Classification

Even when parts are visually similar, they can be separated and classified into groups based on pre-defined measurement tolerances.

Visual Feature Recognition

Beyond size, the system also inspects surface characteristics, edges, and shape profiles to ensure precise identification.

Automated Sorting & Verification

Recognized parts can be automatically sorted, counted, and verified against design specifications, ensuring error-free assembly and packaging.

Benefits for Manufacturers

Error Reduction – Eliminates manual mistakes in part recognition and assembly.

Consistency & Speed – Delivers high-speed, repeatable results across thousands of parts.

Micron-Level Precision – Detects even the smallest dimensional variation that may impact functionality.

Scalability – Easily adaptable to new part designs or product lines without heavy re-engineering.

Integration with Automation – Works seamlessly with robotic handling systems, conveyors, and PLCs.

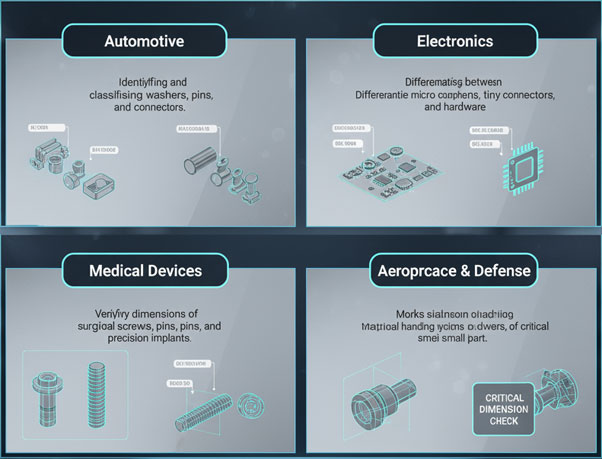

Applications Across Industries

Intelgic’s small part recognition solution is widely applicable across industries such as:

Automotive – Identifying and classifying fasteners, washers, pins, and connectors.

Electronics – Differentiating between micro components, tiny connectors, and hardware.

Medical Devices – Verifying dimensions of surgical screws, pins, and precision implants.

Aerospace & Defense – Ensuring dimensional accuracy of critical small parts.

A Complete Turnkey Solution

Intelgic delivers the entire ecosystem—from imaging hardware (industrial cameras, precision lenses, specialized lighting) to motion control systems and its proprietary Live Vision AI software. This turnkey approach ensures manufacturers get a fully integrated solution for high-accuracy part recognition and classification.