AI-Powered Visual Inspection for Automotive Sheet Metal Parts

Published on: Oct 09, 2025

Written by: Content team, Intelgic

AI-Powered Inspection for Welded and Coated Sheet Metal Parts

Intelgic’s machine vision system automates defect detection on complex-shaped sheet metal parts — even on fast-moving hanging conveyors. Reduce returns, catch defects early, and deliver zero-defect components to your customers.

In the automotive industry, sheet metal components are everywhere — from body panels and brackets to seat frames, structural reinforcements, engine bay components, and more. These parts are manufactured through processes like welding, bending, punching, and powder coating, often forming complex 3D geometries with tight tolerances.

To meet global quality standards and customer expectations, it’s crucial to inspect every part thoroughly before it moves to final assembly or shipping. However, manual inspection of these parts — especially while moving on a hanging conveyor — is error-prone, inconsistent, and labor-intensive.

The Challenge: Visual Defects in Sheet Metal Parts

The complexity of sheet metal part inspection arises from:

- Irregular shapes and orientations

- Varying finishes (bare metal, painted, powder-coated)

- Shiny or matte surfaces

- High throughput lines (hanging conveyors, overhead chains)

- Limited lighting and accessibility in real-world factories

Common defects include:

|

Defects |

Description |

|

Burrs and Sharp Edges |

Leftover material from punching or trimming |

|

Cracks and Fractures |

Caused by stress in bending, welding, or forming |

|

Welding Defects |

Porosity, incomplete welds, over-welding, splatter |

|

Surface Dents or Warping |

Handling or forming issues |

|

Paint or Powder Coating Defects |

Uneven coating, drip marks, dust particles, missed spots |

|

Holes or Cutout Errors |

Incorrect laser cutting or missing features |

|

Foreign Particles |

Dust, hair, debris stuck before coating |

These issues often escape manual detection and lead to costly customer complaints, rejections, or warranty claims.

Intelgic’s Solution: AI + Vision for Sheet Metal Part Inspection

Intelgic offers a machine vision AI-based inspection system designed specifically for complex-shaped sheet metal parts moving on hanging conveyors or jig-based transfer systems.

Our system ensures 100% in-line, real-time inspection without interrupting the production flow.

Key Capabilities

- Multi-camera setup for 360° coverage

- Specialized lighting to handle metallic, matte, or coated surfaces

- AI-based defect detection — trained on part geometry and defect types

- Robotic vision or motorized camera rigs for dynamic tracking

- Real-time alerts and reporting dashboard

- Integration with PLC/MES/ERP systems

AI That Understands Complex Parts

Our Live Vision AI software is engineered to:

- Automatically segment the part based on geometry

- Detect small cracks, burrs, holes, and splatter even in hard-to-see areas

- Validate presence of all weld joints and holes as per CAD/design

- Inspect paint or coating consistency and flag visual anomalies

- Operate reliably on moving conveyors or static stations

The system adapts to different part variants using “inspection recipes” and supports region-specific defect thresholds.

Integration with Hanging Conveyor Lines

Sheet metal parts often move through overhead conveyors during:

- Welding stations

- Surface treatment and cleaning

- Powder coating or painting

- Drying and curing zones

- Final quality inspection

Intelgic’s system is designed to inspect parts in motion, using trigger sensors or encoder-based tracking to capture synchronized images as the part moves. The cameras can be mounted on:

- Static positions around the conveyor path

- Sliding tracks or robotic actuators for angle adjustment

- Smart camera tunnels for full coverage in limited space

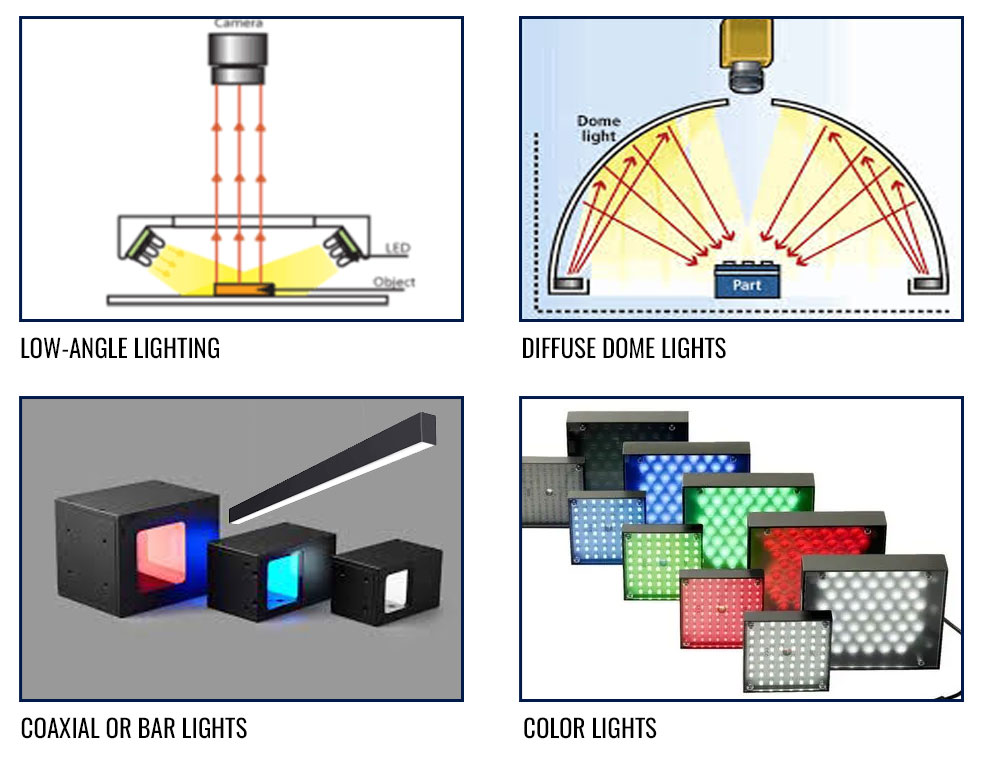

Lighting Optimization for Metallic and Coated Surfaces

Lighting plays a critical role in defect visibility. Intelgic uses:

- Low-angle lighting to reveal burrs and cracks

- Diffuse dome lights to minimize glare on coated surfaces

- Coaxial or bar lights for weld seam enhancement

- Color lights to detect discoloration or foreign particles

Lighting is dynamically controlled by the system based on the part surface and defect type.

Business Impact

By deploying Intelgic’s solution, automotive manufacturers achieve:

- Reduced customer complaints and costly returns

- Consistent quality inspection across shifts and lines

- Faster detection and resolution of process issues

- Lower warranty and rework costs

- Traceable inspection records for audits and compliance

- Better customer satisfaction and brand trust

Use Cases & Industries

- Automotive Tier 1 & Tier 2 suppliers

- OEM manufacturing units

- Sheet metal and fabrication vendors

- Powder coating service providers

- EV chassis and frame component supplier

Optional Modules

- Digital Quality Certificate (DQC) generation per part

- Analytics Dashboard (shift-wise defect trends, part-wise failure rates)

- Cloud dashboard or On-premise deployment

- Automated segregation of bad parts using robotic arms or diverters