Roofing Material Inspection in Manufacturing Using Machine Vision AI

Published on: May 28, 2025

Written by: Content team, Intelgic

Roofing Material Inspection in Manufacturing Using Machine Vision AI

In the fast-paced world of manufacturing, achieving impeccable quality for roofing materials is critical. Each metal sheet, shingle, tile, or membrane must flawlessly meet strict standards to guarantee strength, longevity, and performance once installed. However, tiny imperfections—often invisible to the human eye—can silently compromise the product’s reliability. Traditional manual inspections can’t keep up: they are slow, inconsistent, and limited in detecting these microscopic defects.

That’s where Machine Vision AI steps in as a powerful game-changer. By fusing ultra-high-resolution imaging with advanced artificial intelligence, manufacturers can instantly and accurately identify even the smallest flaws on the production line. This breakthrough technology not only ensures unmatched quality control but also reduces waste and dramatically speeds up manufacturing workflows—bringing precision and efficiency to a whole new level.

Common Defects in Roofing Material Manufacturing

During manufacturing, roofing materials may develop various types of defects, including:

-

Micro-cracks: Tiny fissures caused by stresses during forming or cooling processes.

-

Pits and pores: Small surface cavities often resulting from material impurities or irregularities in the manufacturing process.

-

Scratches and abrasions: Surface damages that may occur during handling, finishing, or transportation.

-

Delamination or blistering: Separation within layered materials indicating bonding or adhesion issues.

-

Corrosion initiation spots: Early signs of oxidation that can compromise material integrity over time.

-

Embedded foreign particles: Contaminants introduced during processing that affect surface quality.

Detecting these flaws early on the production line is essential to prevent defective products from reaching customers and to optimize manufacturing processes.

Manufacturing Inspection Challenges

Inspecting roofing materials on a manufacturing line involves several significant challenges:

-

High production speeds: Fast-moving manufacturing lines often make it challenging for traditional inspection systems to detect tiny micron-level defects, as the rapid pace can cause subtle flaws to be overlooked or missed entirely.

-

Varied defect types: A wide range of potential defects demands highly sensitive detection capabilities capable of identifying even the smallest and most subtle flaws.

-

Reflective, uneven, and color-coated surfaces: Roofing materials, especially color-coated ones, often have shiny or textured finishes that cause glare and shadows, making it difficult to capture clear and accurate images.

-

Environmental contaminants: Dust, oil residues, and other surface contaminants can obscure defects and complicate the inspection process.

-

Need for consistency: Quality control must be objective and uniform, eliminating the variability and subjectivity inherent in human inspections.

How Machine Vision AI Overcomes Roofing Materials Inspection Challenges

Machine Vision AI systems are uniquely designed to tackle the complex challenges faced during roofing material inspection in manufacturing environments. By integrating cutting-edge components and technologies, these systems deliver unparalleled accuracy, speed, and reliability.

High-Resolution Imaging for Micron-Level Precision

To accurately detect microscopic defects in roofing materials, Machine Vision AI systems employ advanced imaging technologies customized for different material types and inspection needs:

-

Line Scan Imaging:

-

Ideal for continuous, high-speed inspection of long, uniform roofing materials such as metal sheets, membranes, and large rolls of synthetic roofing films.

-

Captures images line by line, producing seamless, high-resolution scans of entire lengths to detect tiny defects like micro-cracks, pits, or scratches along the material’s surface.

-

-

Area Scan Imaging:

-

Best suited for inspecting discrete, irregularly shaped roofing materials such as shingles, tiles, or smaller coated panels.

-

Captures full-frame images of specific sections, allowing detailed examination of complex surfaces and textured finishes to identify minute flaws.

-

Advanced Lighting Techniques to Manage Surface Reflectivity

Inspecting roofing materials can be challenging due to their shiny, reflective, or textured surfaces that often cause glare, reflections, and shadows. To ensure clear visibility of defects under these conditions, advanced lighting techniques are employed to optimize image quality and reveal hidden imperfections:

-

Diffuse Lighting:

Softly scatters light evenly across the material surface, reducing harsh reflections and glare, ideal for smooth and glossy roofing materials.

-

Coaxial Lighting:

Directs light precisely along the camera’s line of sight, enhancing subtle surface features and making small defects more visible, especially effective for detecting fine scratches and micro-cracks.

-

Structured Lighting:

Projects specific light patterns onto textured or uneven surfaces, highlighting contours and surface irregularities to expose defects that might be missed with uniform lighting.

AI-Powered Software for Real-Time Defect Detection

In modern roofing material manufacturing, the integration of AI-powered software within machine vision systems has revolutionized quality control. By leveraging artificial intelligence and deep learning, these systems perform real-time inspection and analysis of surface defects with exceptional speed and precision—ensuring that even the most minute flaws are detected early in the production process. The result is a highly reliable, scalable, and autonomous inspection solution that enhances both quality and productivity.

Key capabilities include:

-

Real-Time Image Analysis

AI algorithms process high-resolution images on-the-fly, detecting, localizing, and measuring a wide range of defects such as micro-cracks, blisters, delamination, and surface inconsistencies.

-

Deep Learning for Defect Classification

Trained on large datasets, deep learning models accurately classify defect types and patterns, distinguishing between acceptable variances and true quality issues.

-

Adaptive Learning & Model Optimization

The AI system continuously improves its performance through data-driven learning, adapting to new defect patterns and variations in material surfaces to reduce false positives and missed detections.

-

Scalability and Integration

Designed for seamless integration into existing manufacturing workflows, the software scales easily to accommodate different roofing materials and production volumes.

Workflow of Roofing Material Inspection in Manufacturing

-

Material Presentation

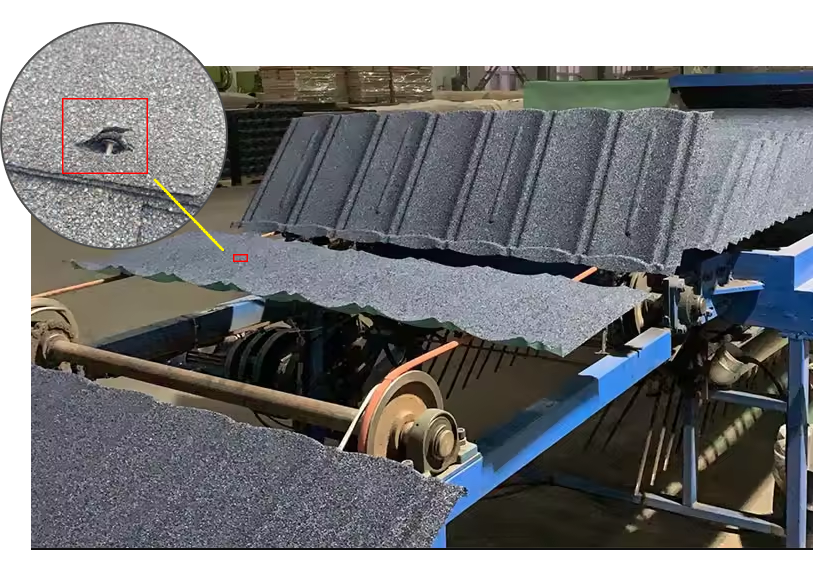

Roofing materials—such as metal sheets, color-coated coils, membranes, or shingles—are conveyed through the production line beneath the inspection station in a continuous and synchronized manner.

-

Image Acquisition

High-resolution line scan or area scan cameras, paired with precision-controlled lighting systems, capture detailed images of the material surface as it moves through the inspection zone.

-

Image Preprocessing

Captured images are immediately processed using AI-enhanced algorithms that normalize lighting, suppress noise, and enhance surface features to highlight potential defect regions.

-

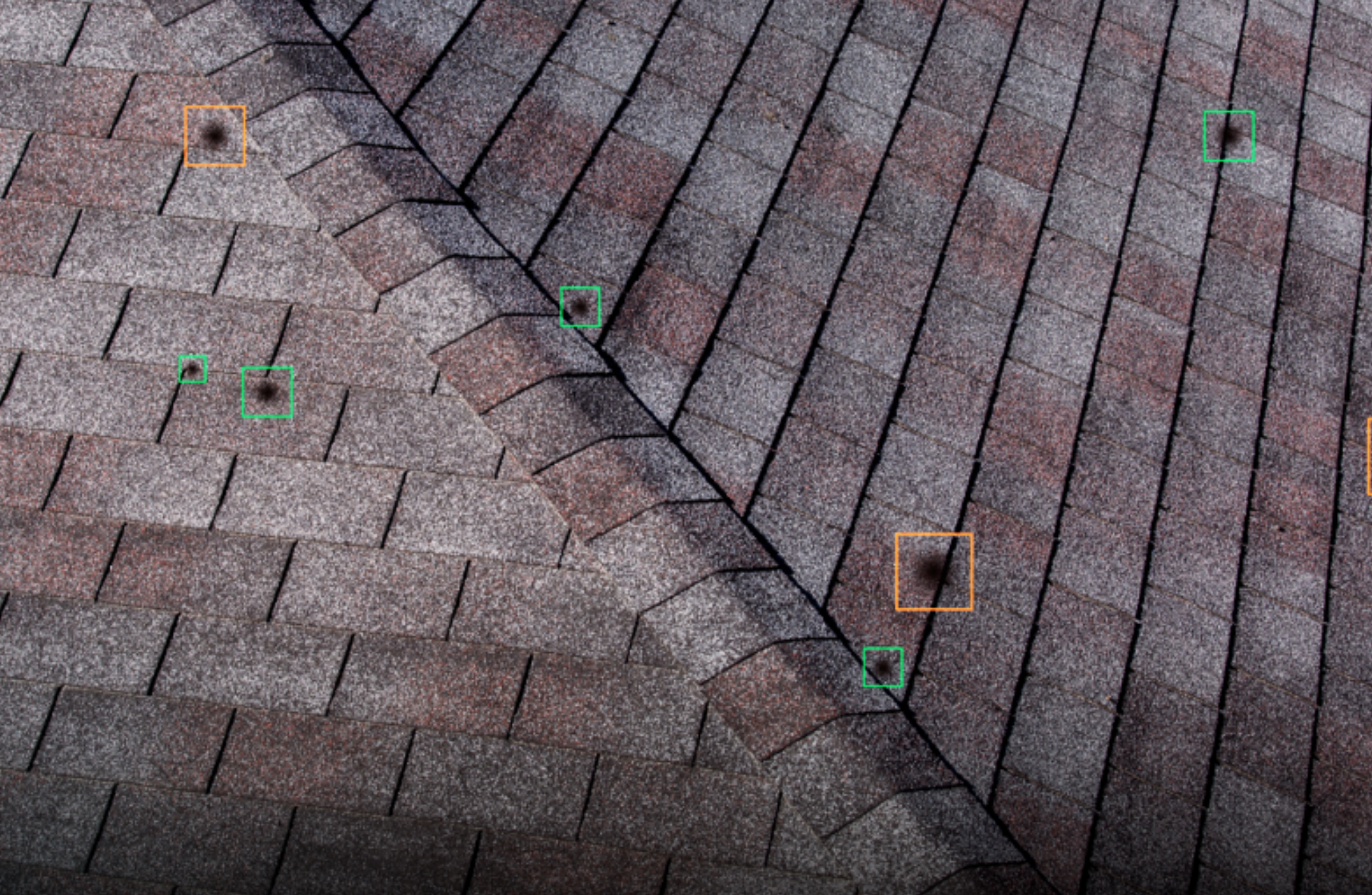

Defect Detection and Classification

In real time, AI models analyze the processed images to detect anomalies, classify defect types (e.g., micro-cracks, pits, scratches, delamination), and perform dimensional measurements with micron-level accuracy.

-

Data Reporting and System Integration

Inspection results, including defect type, size, and location, are transmitted to the central manufacturing execution system (MES) or quality management system (QMS) for real-time decision-making and traceability.

-

Automated Action

Based on predefined quality thresholds, the system flags defective materials for rejection, rework, or diversion, ensuring that only conforming products continue down the production line.

Advantages of Machine Vision AI in Manufacturing Inspection

The implementation of Machine Vision AI in roofing material manufacturing offers significant advantages that redefine the standards of quality control while paving the way for next-generation inspection capabilities:

Key Advantages

-

Micron-Level Accuracy

Detects surface defects that are often invisible to the human eye, ensuring the highest standards of material quality.

-

High-Speed, Non-Stop Inspection

Performs real-time analysis that keeps pace with fast-moving production lines without causing bottlenecks or delays.

-

Consistent and Objective Quality Control

Eliminates subjectivity and variability inherent in manual inspection, delivering repeatable and reliable results.

-

Early Defect Detection

Identifies issues at the source, minimizing rework, reducing material waste, and preventing defective products from progressing further in the production cycle.

-

Seamless Digital Traceability

Records and logs inspection data in real-time, enabling compliance with industry standards and supporting continuous process optimization.

Emerging Trends and Innovations:

-

Integration with robotic handling for automated defect removal or rework.

-

Use of multispectral imaging to detect subsurface or chemical defects.

-

Predictive analytics powered by AI to anticipate manufacturing faults and optimize process parameters.

-

Increased automation through end-to-end AI-driven quality control systems.

Driving Quality Excellence: Intelgic’s AI-Powered Roofing Material Inspection Solutions

Intelgic’s Live Vision software delivers a powerful and fully integrated solution for inspecting roofing materials in high-speed manufacturing environments. Purpose-built to address the complex challenges of surface inspection, the platform seamlessly blends high-resolution imaging, advanced lighting technologies, and AI-powered analytics to detect even the most minute surface defects—ensuring inspection accuracy down to the micron level.

Designed to operate in real time without disrupting production flow, Live Vision enables manufacturers to maintain rigorous quality control standards while significantly improving operational efficiency. Whether inspecting metal sheets, color-coated coils, asphalt shingles, or membrane rolls, the system adapts to a wide variety of roofing substrates and finishes with unmatched precision.

With Intelgic’s domain expertise and technological innovation, roofing material manufacturers benefit from:

-

Enhanced product quality, by consistently identifying and eliminating defective units before they progress through the line.

-

Reduced material waste, thanks to early-stage defect detection that minimizes rework and scrap.

-

Increased throughput, as the system supports high-speed inspection in sync with modern production rates.

-

Data-driven decision-making, through detailed defect analytics, traceability, and system integration capabilities.

By setting new benchmarks in speed, accuracy, and automation, Intelgic is transforming roofing material inspection from a reactive task into a strategic advantage—empowering manufacturers to lead in quality, efficiency, and customer satisfaction.