Revolutionizing Automobile Parts Counting with AI and Advanced Imaging Technology

Published on: Jan 30, 2025

Written by: Content team, Intelgic

Revolutionizing Automobile Parts Counting with AI and Advanced Imaging Technology

The automobile industry is a fast-paced sector where precision, efficiency, and accuracy are crucial. One of the most significant challenges faced by manufacturers is the accurate counting of automobile parts, which plays a vital role in inventory management, quality assurance, and production efficiency. Traditional methods of counting parts manually are prone to errors, labor-intensive, and inefficient. However, with the advent of Artificial Intelligence (AI) and advanced imaging technologies, automated counting systems have revolutionized the industry. This article explores the challenges of manual counting, the cutting-edge technologies employed in AI-driven counting, the workflow of automated systems, and how Intelgic is pioneering innovation in automobile parts counting.

Challenges in Traditional Automobile Parts Counting

Traditional methods of automobile parts counting, which rely on manual labor or basic automated systems, are fraught with numerous challenges. These limitations often lead to inefficiencies, errors, and increased costs. Below are the key challenges faced in traditional automobile parts counting:

Human Error:

- Manual counting is prone to mistakes due to fatigue, distraction, or repetitive tasks.

- Even experienced workers can miscount, especially when dealing with large volumes of small or similar-looking parts.

Time-Consuming Process:

- Manual counting is slow and labor-intensive, leading to bottlenecks in production lines.

- The time required to count parts manually can delay inventory management and production schedules.

Inability to Handle Complex Parts:

- Irregularly shaped, overlapping, or densely packed parts are difficult to count accurately using traditional methods.

- Reflective or shiny surfaces can further complicate the counting process.

Lack of Real-Time Data:

- Traditional systems often lack real-time data processing capabilities, leading to delays in identifying discrepancies.

- Batch processing or manual data entry can result in outdated or inaccurate inventory records.

High Labor Costs:

- Manual counting requires a significant workforce, increasing operational costs.

- Training and retaining skilled workers for repetitive tasks can be challenging and expensive.

Limited Scalability:

- Manual or basic automated systems struggle to scale with increasing production demands.

- Handling large volumes of parts efficiently becomes a significant challenge.

Inconsistent Accuracy:

- Accuracy levels vary depending on the skill and attention of the worker or the limitations of the counting system.

- Inconsistent counting results can lead to inventory discrepancies.

The Technological Leap: Cameras, Lighting, and AI Software

The integration of advanced cameras, sophisticated lighting systems, and AI software has ushered in a new era of automobile parts counting. These technologies work in concert to overcome the limitations of traditional methods, offering unparalleled accuracy, speed, and flexibility.

Cameras for Automobile Parts Counting:

High-Resolution Machine Vision Cameras:

- Capture detailed images of parts, even when they are small or intricately designed.

- Essential for identifying and differentiating parts with complex geometries or textures.

Line Scan Cameras:

- Enable real-time counting of fast-moving parts on production lines.

- Reduce motion blur, ensuring clear and precise image capture.

Multi-Spectral and Hyperspectral Cameras:

- Capable of capturing images beyond the visible spectrum, such as infrared or ultraviolet.

- Useful for identifying parts with unique material properties or surface finishes.

3D Cameras:

- Provide depth perception, allowing the system to count parts in three dimensions.

- Particularly effective for counting irregularly shaped or overlapping parts.

Lighting Systems

Lighting plays a pivotal role in ensuring the accuracy of parts counting. Proper illumination enhances the contrast between parts and their background, making it easier for cameras to capture clear images.

LED Strobe Lighting:

- Synchronized with camera shutters to freeze motion, eliminating blur during high-speed counting.

- Ideal for capturing clear images of fast-moving parts on conveyor belts.

Diffused Lighting:

- Provides uniform illumination, reducing shadows and reflections.

- Particularly effective for counting shiny or reflective parts, such as metal components.

Backlighting:

- Illuminates parts from behind, creating high-contrast silhouettes.

- Useful for counting parts with complex shapes or transparent materials.

Structured Lighting:

- Projects patterns (e.g., grids or lines) onto parts to enhance surface details.

- Helps in identifying and counting parts with intricate designs or textures.

AI Software for Real-Time Counting:

The true game-changer in Automobile parts counting is Intelgic’s Live Vision software, which leverages machine learning algorithms to analyze images and count parts with remarkable accuracy. This software can be trained to recognize and differentiate between various parts, even when they are irregularly shaped or densely packed. This capability is particularly valuable in the automotive industry, where parts can vary widely in size, shape, and color.

One of the key advantages is its ability to process data in real time. This means that parts can be counted as they move along a production line, without the need for manual intervention or batch processing. Real-time counting not only speeds up the process but also allows for immediate detection of discrepancies, enabling prompt corrective action.

Workflow of AI-Driven Automobile Parts Counting

The workflow of an AI-driven parts counting system typically involves several key steps:

- Image Acquisition: High-resolution machine vision cameras capture images of the parts as they move along the production line. The cameras are synchronized with lighting systems to ensure optimal image quality.

- Image Preprocessing: The captured images are preprocessed to enhance their quality. This may involve adjusting brightness and contrast, reducing noise, and correcting for distortions.

- Object Detection and Recognition: AI algorithms analyze the preprocessed images to detect and recognize individual parts. The algorithms are trained to differentiate between different types of parts and to ignore background noise or irrelevant objects.

- Counting and Data Logging: Once the parts are detected and recognized, the AI software counts them and logs the data. The counting process is highly accurate, with the ability to handle complex scenarios such as overlapping parts or parts with irregular shapes.

- Real-Time Monitoring and Reporting: The counted data is transmitted in real time to a central monitoring system, where it can be visualized and analyzed. Any discrepancies or anomalies are flagged for immediate attention.

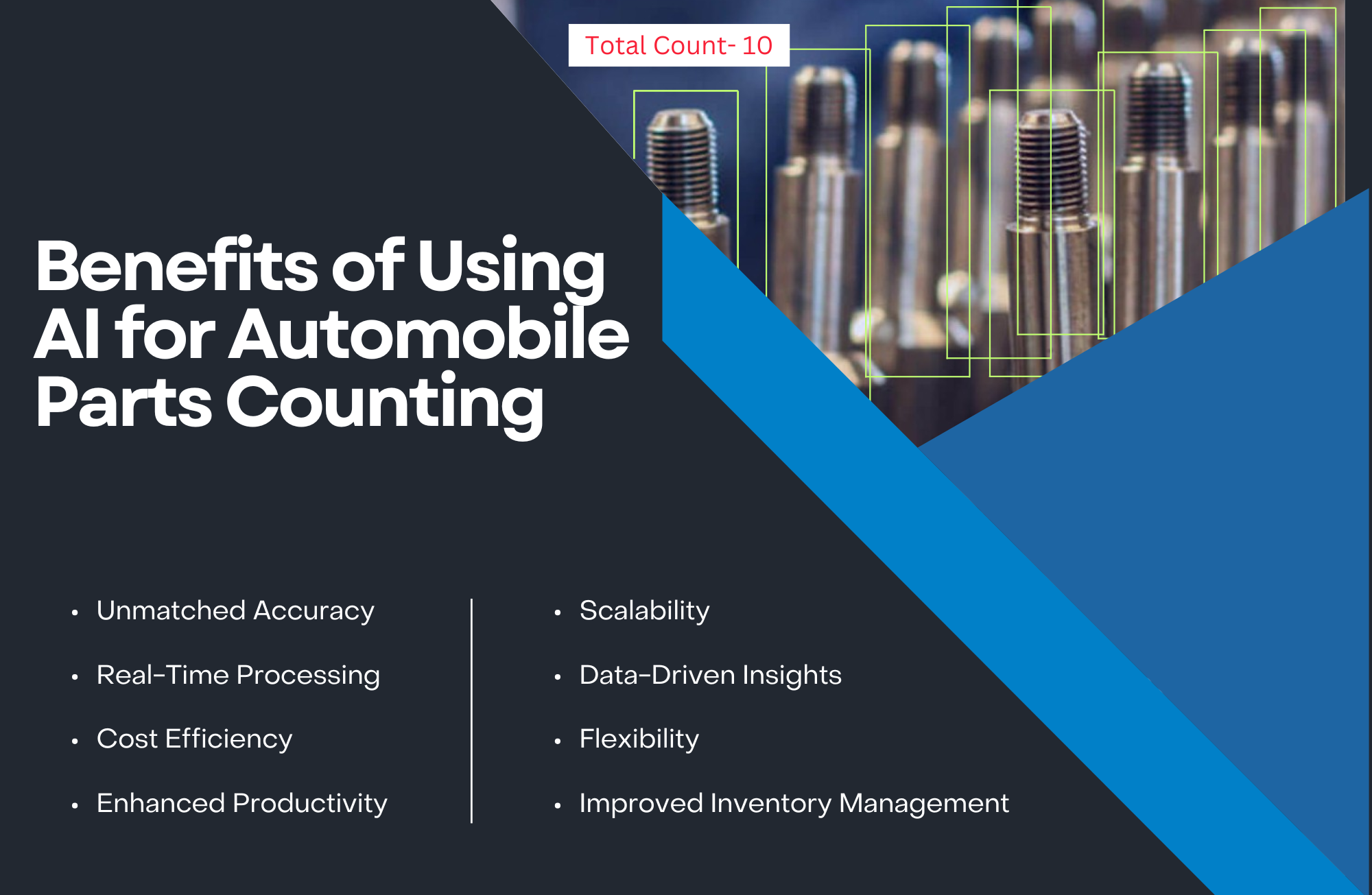

Benefits of Using AI for Automobile Parts Counting

- Unmatched Accuracy: AI systems achieve near-perfect counting accuracy, minimizing errors even with complex or irregular parts.

- Real-Time Processing: Enables instant counting and immediate detection of discrepancies, reducing delays.

- Cost Efficiency: Reduces labor costs and minimizes losses from counting errors or production delays.

- Enhanced Productivity: Speeds up the counting process, allowing faster production cycles and improved throughput.

- Scalability: Easily adapts to different parts, volumes, and production environments without significant reconfiguration.

- Data-Driven Insights: Provides real-time analytics to optimize workflows and improve decision-making.

- Flexibility: Handles diverse part types, shapes, and sizes, including mixed batches and reflective surfaces.

- Improved Inventory Management: Ensures accurate stock levels, reducing overstocking or shortages.

Intelgic's Expertise in Automobile Parts Counting

Intelgic stands at the forefront of innovation in the realm of AI-powered automobile parts counting, offering cutting-edge solutions tailored to the unique demands of the automotive industry. With a deep understanding of the challenges inherent in traditional counting methods, Intelgic has developed a suite of advanced technologies that seamlessly integrate high-resolution cameras, sophisticated lighting systems, and state-of-the-art AI software.

Intelgic’s solutions are designed to deliver

- Unparalleled Accuracy: Intelgic’s solutions ensure near-perfect counting precision, even for complex or irregular parts.

- High-Speed Processing: Enables real-time counting, significantly reducing production delays.

- Adaptability: Designed to handle diverse parts, shapes, and production environments with ease.

- Operational Efficiency: Empowers manufacturers to streamline workflows and boost productivity.

- System Integration: Seamlessly integrates with existing production lines for hassle-free implementation.

- Optimal Performance: Delivers consistent, high-quality results to meet the demands of modern automotive manufacturing.

The integration of advanced cameras, lighting systems, and AI-driven software has revolutionized automobile parts counting, addressing the inefficiencies and challenges of traditional methods. By leveraging these cutting-edge technologies, manufacturers can achieve unprecedented levels of accuracy, speed, and operational efficiency. Real-time data processing, scalability, and adaptability make AI-powered systems indispensable in modern automotive production lines.

Intelgic’s expertise in this domain further amplifies these benefits, offering tailored solutions that combine innovative technology with seamless integration and comprehensive support. Their commitment to precision and efficiency empowers manufacturers to overcome traditional limitations, reduce costs, and enhance productivity.