Quality Inspection in Manufacturing Using AI in 2025

Published on: Nov 19, 2024

Written by: Soumen das

Quality Inspection Trends in Manufacturing Using AI in 2025

As manufacturing processes become increasingly complex and customers are more sensitive to the quality than ever, the quality inspection has become a critical focus for ensuring product integrity, customer satisfaction, and regulatory compliance. In 2025, Artificial Intelligence (AI) is revolutionizing quality inspection, enabling manufacturers to achieve unprecedented levels of accuracy, speed, and efficiency. By integrating AI-driven systems into production lines, manufacturers can detect defects, analyze trends, and adapt Automated Optical Inspection (AOI) systems in the inspection process, setting new benchmarks for quality assurance.

Key Technologies in 2025 for Quality Inspection in Manufacturing

Machine Vision AI

Machine vision systems use high-resolution industrial cameras and sensors to capture detailed images of products. AI algorithms process these images to detect anomalies, defects, measure dimensions, and assess quality.

Example: Detecting surface scratches, dents, or discoloration on automotive components.

Deep Learning AI

Deep learning models, such as convolutional neural networks (CNNs), are trained on large datasets of images with good and rejected products to recognize anomalies with exceptional accuracy. The demand of such AI software that are specially trained for anomaly detection will increase and is a trend in 2025 for automating inspection processes in manufacturing.

Example: Identifying fabric weaving defects in the textile industry or classifying defective electronic components.

Robotic Integration

Customized inspection systems are becoming popular and will set a new trend in 2025. Robotic arms are in use for designing and developing customized inspection systems. AI-enabled robotic arms equipped with cameras and sensors can perform inspection tasks with precision, reducing human intervention.

Example: Inspecting bores or threads in metal devices or tubes.

Customized Imaging

Customized imaging is required for automating complex inspection processes. Demand for micron level defect detection in high speed lines is increasing especially for sheets such as foils paper, shiny sheets, films, aluminum sheets and many more. To inspect such reflective sheets, customized CIS imaging is being used. The demand of CIS will increase in 2025.

Example: Inspecting micron level defects in color coating on aluminum sheets.

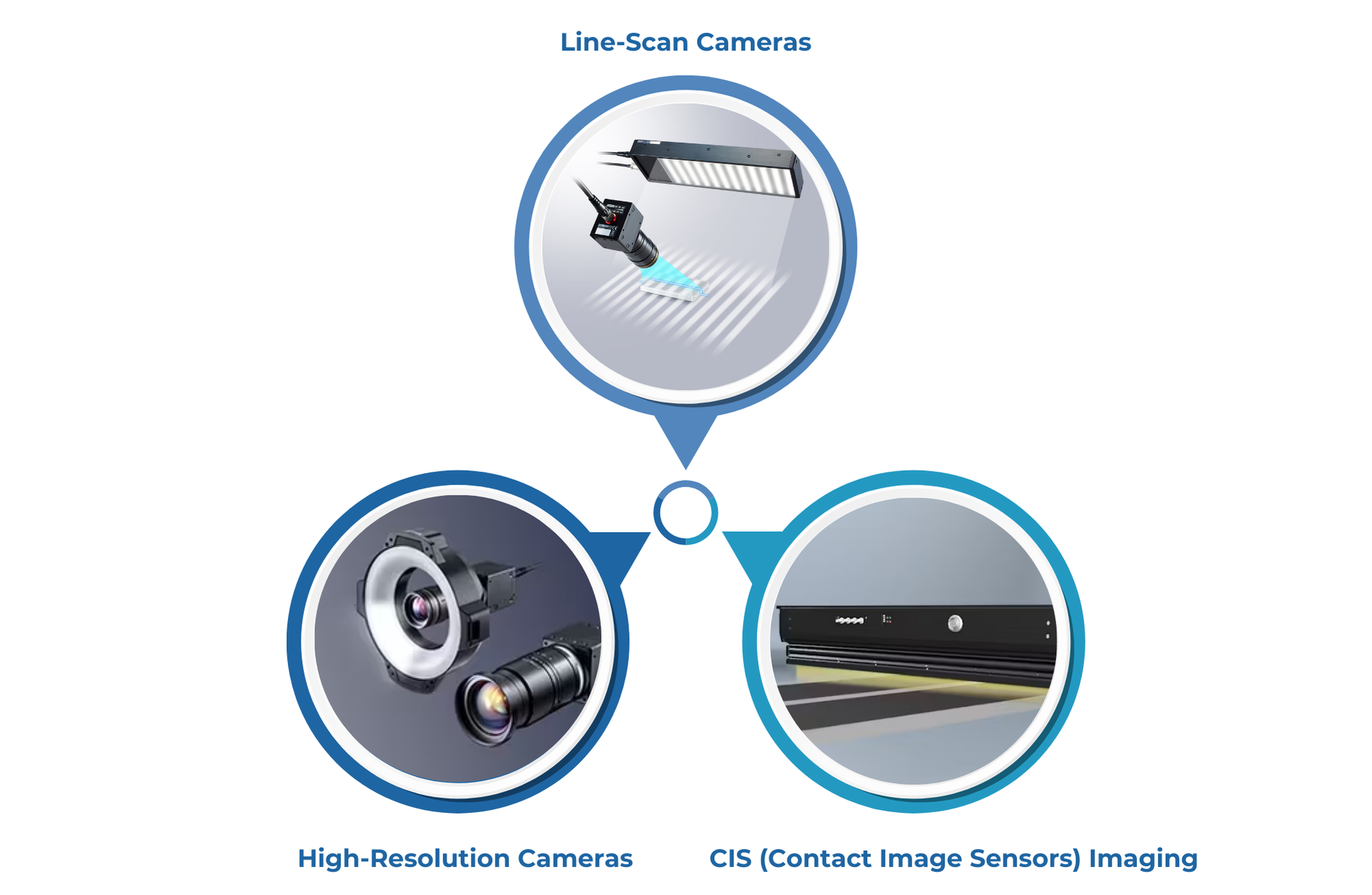

The Role of Imaging Systems in AOI for 2025

In 2025, imaging systems are central to AOI systems, with innovations in camera technology enabling manufacturers to achieve micron-level defect detection even at high production speeds. Here’s a closer look at the imaging systems driving inspection automation:

Line-Scan Cameras

- Technology Overview: Line-scan cameras capture images one line at a time as the product moves past the camera. They are designed for high-speed production environments, offering high resolution and precision for continuous inspection.

- Applications: Line-scan cameras are used in industries such as textiles, paper, electronics, and food processing, where products move rapidly on conveyor belts.

- 2025 Trends:

- The demand for 8k and 16k line-scan cameras is surging, driven by the need to inspect smaller defects without slowing down production.

- Manufacturers are prioritizing high-speed anomaly detection, ensuring that even microscopic defects in high-gloss or reflective materials are identified.

- Line-scan cameras are increasingly used for inspecting shiny materials like films, glass, and foil paper, where achieving defect-free surfaces is paramount for customer satisfaction.

CIS (Contact Image Sensors) Imaging

- Technology Overview: CIS imaging systems use a line of sensors placed close to the material to capture high-resolution images. These sensors excel in inspecting shiny or reflective surfaces.

- Applications: Widely used for inspecting materials like plastic films, glass sheets, and metal foils, where traditional imaging struggles due to glare and reflectivity.

- 2025 Trends:

- CIS imaging, combined with state-of-the-art AI algorithms, is becoming more popular in industries producing shiny or transparent materials.

- Manufacturers are leveraging CIS systems for their ability to capture edge-to-edge images with minimal distortion, ensuring comprehensive inspection of even challenging surfaces.

High-Resolution Cameras

- Technology Overview: These cameras are essential for applications requiring exceptional detail, especially for detecting defects smaller than 10 microns.

- Applications: Used in precision industries like semiconductors, electronics, and medical devices.

- 2025 Trends:

- Ultra-high resolution cameras are becoming standard for industries that require micron-level defect detection.

- These cameras are paired with advanced optics to inspect tiny features, ensuring consistent quality in industries with stringent tolerances.

Scalability of AI-Powered AOI Systems

One of the defining features of AI-powered AOI systems in 2025 is their scalability:

Horizontal Scaling:

AOI systems can be implemented across multiple production lines with minimal additional cost, enabling manufacturers to standardize quality control across facilities.

Vertical Scaling:

AI models can be continuously updated with new product images and defect types, allowing manufacturers to adapt to emerging quality challenges.

This adaptability is critical as manufacturers face increasing demands for defect detection across diverse product categories.

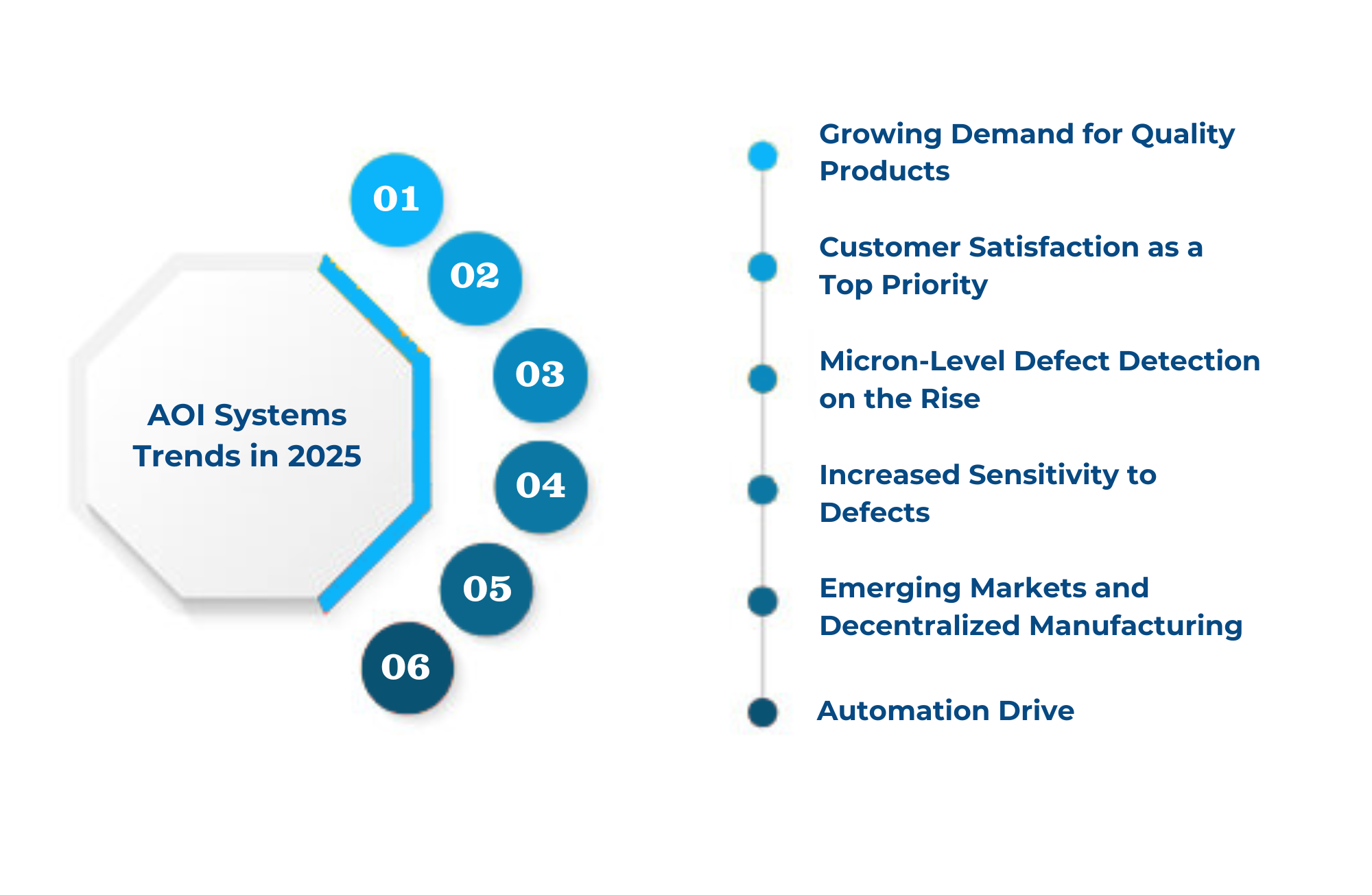

AOI Systems Trends in 2025

Growing Demand for Quality Products

Customers expect flawless products, and even minor defects can lead to dissatisfaction or returns. Manufacturers are using AOI systems to achieve consistent quality and gain a competitive edge.

Customer Satisfaction as a Top Priority

In an era of heightened consumer awareness, quality assurance has become synonymous with brand trust. AOI systems enable manufacturers to ensure that every product meets or exceeds customer expectations.

Micron-Level Defect Detection on the Rise

As products become more intricate and miniaturized, the demand for detecting defects at the micron level has grown exponentially. AOI systems equipped with ultra-high-resolution cameras are addressing this need.

Increased Sensitivity to Defects

Customers are more sensitive than ever to imperfections, particularly in luxury goods, medical devices, and electronics. This has driven the adoption of AOI systems capable of detecting even the smallest irregularities.

Emerging Markets and Decentralized Manufacturing

Countries like the USA, India, Vietnam, the Middle East, and Europe are becoming popular choices for manufacturers for decentralized manufacturing. Local manufacturing units are coming up to reach out to every local market. These units are focusing on implementing AOI systems to meet stringent quality standards while maintaining production efficiency.

Automation Drive

Manual inspection, plagued by inconsistency and human error, is no longer sufficient to meet the demands of modern manufacturing. Manufacturers are rapidly transitioning to AOI systems for reliable, automated inspection processes.

The manufacturing industry in 2025 is characterized by the relentless pursuit of quality, precision, and efficiency. AOI systems are at the heart of this transformation, enabling manufacturers to achieve micron-level defect detection, adapt to evolving customer demands, and scale quality control operations seamlessly.

Driven by innovations in imaging systems like line-scan cameras, CIS imaging, and high-resolution cameras, AOI systems are setting new benchmarks for inspection automation. As competition grows and customers become increasingly selective, manufacturers leveraging AOI systems will be well-positioned to deliver superior products and maintain a competitive edge in the global market.