Mobile Case Inspection in Manufacturing with AI

Published on: Jan 31, 2025

Written by: Content team, Intelgic

Mobile Case Inspection in Manufacturing with AI

In the rapidly evolving realm of consumer electronics, the demand for impeccably crafted mobile phone cases has reached unprecedented levels. As smartphones continue to play an indispensable role in everyday life, the aesthetic appeal and functional reliability of their protective cases have become paramount for manufacturers. To address this need, the integration of industrial-grade machine vision cameras, sophisticated illumination systems, and artificial intelligence (AI) has redefined the landscape of mobile case inspection. This article explores the cutting-edge technologies powering this transformation, the streamlined workflow of the inspection process and its transformative advantages.

Types of Defects in Mobile Case Inspection

Mobile case inspection ensures the quality and functionality of smartphone protective cases. Defects, arising from diverse materials and manufacturing processes, are categorized into surface, structural, aesthetic, functional, and material defects.

1. Surface Defects

- Scratches: Fine marks from abrasion during handling or production.

- Dents: Depressions caused by impact or pressure.

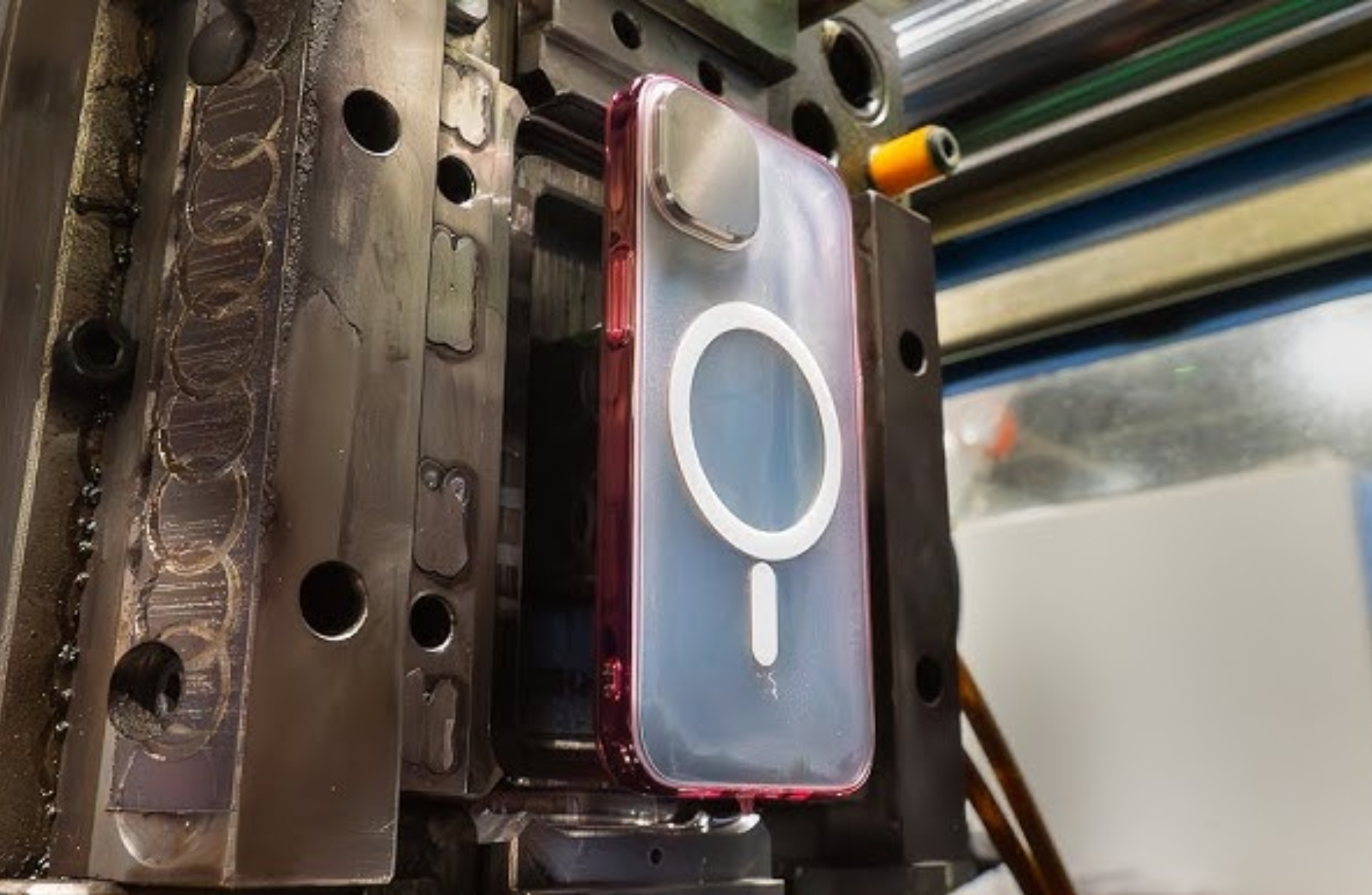

- Cracks: Fractures compromising structural integrity.

- Pits/Pinholes: Small holes from air bubbles or impurities.

- Blemishes: Discolored or uneven patches.

- Burrs: Rough edges from cutting or molding.

2. Structural Defects

- Misalignment: Improperly aligned buttons, ports, or cutouts.

- Warping: Deformation due to uneven cooling or stress.

- Thickness Variations: Inconsistent thickness affecting protection.

- Weak Spots: Thin or weak areas prone to damage.

- Delamination: Separation of layers in multi-material cases.

3. Aesthetic Defects

- Discoloration: Uneven or unintended color variations.

- Stains: Marks from contamination during production.

- Inconsistent Textures: Deviations in surface texture.

- Printing Errors: Misaligned, smudged, or incomplete prints.

- Glue Residue: Excess adhesive visible on seams or joints.

4. Material Defects

- Air Bubbles: Trapped air causing weak spots or imperfections.

- Contaminants: Foreign particles affecting durability.

- Material Cracking: Brittleness from poor-quality materials.

- Inconsistent Hardness: Variations impacting protection.

Technologies Powering Mobile Case Inspection

1. Machine Vision Cameras: The Eyes of Precision

At the heart of any mobile case inspection system lies the machine vision camera. These cameras are designed to capture high-resolution images with exceptional clarity, enabling the detection of even the most minute defects. Unlike conventional cameras, industrial cameras are built to withstand harsh manufacturing environments, offering robustness, reliability, and consistency.

Key features of industrial cameras used in mobile case inspection include:

- High Resolution: Capable of capturing images with resolutions ranging from 5 to 50 megapixels, ensuring that even the smallest imperfections are visible.

- High Frame Rates: Enabling real-time inspection without compromising on speed or accuracy.

- Spectral Sensitivity: Some cameras are equipped with multispectral or hyperspectral imaging capabilities, allowing them to detect defects that are invisible to the human eye.

2. Illumination Systems: Shedding Light on Defects

The quality of inspection is heavily dependent on the lighting conditions under which images are captured. Advanced illumination systems are designed to highlight defects by creating optimal contrast between the defect and the surrounding material Commonly used illumination techniques include:

- LED Ring Lights – Provide uniform lighting to enhance surface defect visibility.

- Diffuse Dome Lights – Minimize reflections and glare, ensuring clearer image acquisition.

- Coaxial Lighting – Helps in detecting fine surface scratches and reflective defects.

- Backlighting – Used for edge and contour detection.

3. AI Software: The Brain Behind the Operation

AI powered Intelgic’s Live Vision Software is the cornerstone of modern defect detection systems. AI algorithms, particularly those based on deep learning, are trained to recognize patterns and anomalies in the captured images. These algorithms can identify defects with a level of accuracy and speed that surpasses human capabilities.

Key components of AI software in mobile case inspection include:

- Convolutional Neural Networks (CNNs): Specialized for image recognition tasks, CNNs are trained on vast datasets of defect images to accurately classify and locate defects.

- Anomaly Detection Algorithms: These algorithms are designed to identify deviations from the norm, even in cases where the defect type has not been explicitly trained.

- Real-Time Processing: AI software is optimized for real-time analysis, ensuring that defects are detected and flagged immediately during the production process.

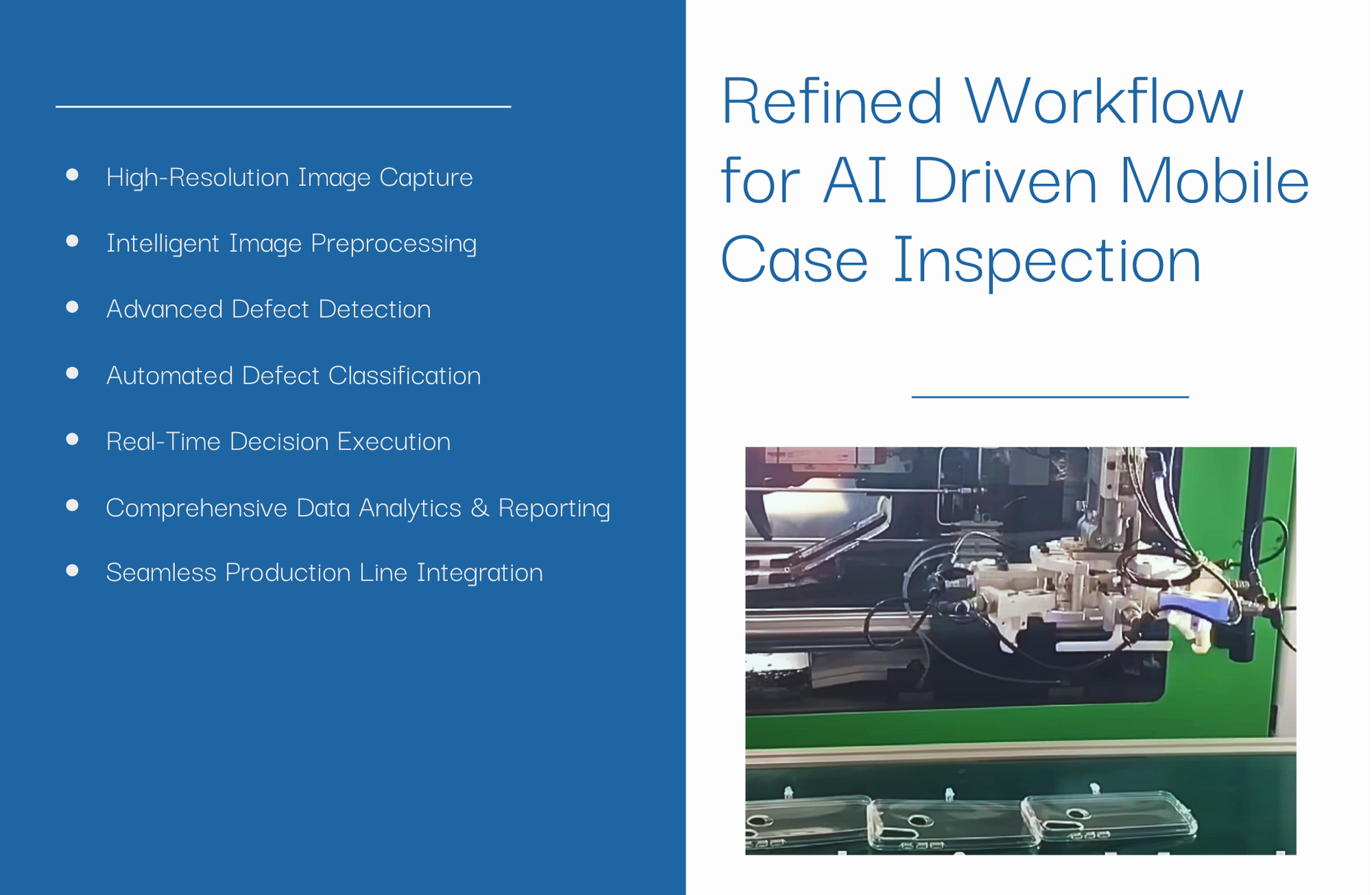

Refined Workflow for AI Driven Mobile Case Inspection

The mobile case inspection process encompasses a meticulously structured approach, ensuring that defects are detected with the utmost precision. The refined workflow is as follows:

- High-Resolution Image Capture: Industrial cameras equipped with optimal lighting systems acquire detailed images of mobile cases from multiple angles.

- Intelligent Image Preprocessing: AI-powered algorithms refine captured images by removing noise, enhancing contrast, and optimizing brightness for superior defect visibility.

- Advanced Defect Detection:The preprocessed images are fed into the AI software, which analyzes them using trained neural networks. The software identifies defects such as scratches, dents, discoloration, and misalignments.

- Automated Defect Classification: The AI system categorizes defects by type and severity, facilitating streamlined decision-making.

- Real-Time Decision Execution: The inspection system instantaneously determines whether a mobile case passes quality standards or is flagged for review.

- Comprehensive Data Analytics & Reporting: AI-driven analytics store inspection data, providing insights for quality control optimization and predictive maintenance.

- Seamless Production Line Integration: The AI system integrates with manufacturing workflows, enabling automatic rejection of defective cases or triggering alerts for manual inspection.

Key Advantages of AI-powered Machine Vision Solution for Mobile Case Inspection

- Exceptional Accuracy: Eliminates human inconsistencies, ensuring superior defect detection precision.

- Accelerated Inspection Speed: High-speed AI algorithms conduct real-time inspections without disrupting production.

- Cost Efficiency: Reduces reliance on manual inspection, optimizing labor and operational costs.

- Adaptive Scalability: AI models can be trained to inspect diverse mobile case designs, adapting to evolving manufacturing trends.

- Data-Driven Quality Optimization: AI-generated analytics provide actionable insights for continuous improvement.

- Minimized False Rejections: AI calibration significantly reduces erroneous defect classifications, improving production yield.

- Effortless System Integration: The AI-driven inspection system seamlessly integrates with existing manufacturing infrastructures.

How Intelgic Excels in Mobile Case Inspection

In an increasingly competitive market where precision and efficiency are paramount, Intelgic has emerged as a leader in mobile case inspection, setting new benchmarks for quality and innovation.Here’s how Intelgic distinguishes itself:

- State-of-the-Art AI Models: Intelgic utilizes advanced deep learning algorithms that continuously evolve, ensuring unmatched defect detection accuracy.

- High-Speed Processing: Intelgic’s AI software works in tandem with high-resolution industrial cameras, delivering real-time defect detection without disrupting production.

- Customizable Solutions: Intelgic provides tailored AI inspection models that align with specific manufacturing needs, ensuring seamless integration and efficiency.

- Cloud & Edge AI Capabilities: Intelgic’s hybrid AI approach leverages both cloud-based and edge AI solutions, enabling rapid processing and remote monitoring.

- User-Friendly Interface: The AI system is designed with an intuitive interface, allowing operators to easily review and adjust inspection parameters.

- Comprehensive Reporting & Analytics: Intelgic’s system provides detailed reports and actionable insights, helping manufacturers enhance quality control and process efficiency.

Conclusion

The convergence of industrial cameras, advanced illumination systems, and AI has transformed mobile case inspection, enabling manufacturers to meet the ever-growing demand for flawless products. By automating the inspection process, these technologies offer unparalleled accuracy, speed, and cost savings, while providing valuable insights for continuous improvement.

Intelgic stands at the forefront of this revolution, offering cutting-edge solutions that set new benchmarks for quality and innovation. As the industry continues to evolve, Intelgic’s commitment to excellence ensures that their clients remain ahead of the curve, delivering products that meet the highest standards of quality and reliability. In the competitive world of consumer electronics, Intelgic’s mobile case inspection solutions are not just a luxury—they are a necessity.