Metal Tube Inner Surface Inspection with Customized Machine Vision AOI

Published on: May 13, 2025

Written by: Content team, Intelgic

Metal Tube Inner Surface Inspection with Customized Machine Vision AOI

Deep within the narrow, reflective corridors of metal tubes—some no wider than a pencil—lies a world invisible to the naked eye, yet critical to the safety and performance of countless systems. In industries like aerospace, automotive, oil & gas, and medical device manufacturing, even the smallest imperfection—whether a microscopic crack, a trace of corrosion, or a barely-there burr—can lead to catastrophic failure.

Traditional inspection tools often falter when faced with the unique challenges of inspecting small-diameter, long-length, and highly reflective inner tube surfaces. The tight spaces, difficult lighting conditions, and need for sub-micron precision demand a new kind of solution.

This is where advanced Machine Vision AOI, paired with custom-built imaging systems and precision-controlled motion mechanics, steps in—bringing to life an intelligent, automated inspection process capable of navigating and analyzing the most inaccessible interiors. With these technologies, manufacturers gain not only unprecedented visibility but also the power to detect, classify, and respond to defects in real time—ensuring unmatched product quality and compliance.

Common Defects in Metal Tube Inner Surfaces

Several defects can affect the performance and integrity of metal tubes. Common defects include:

- Cracks: Weakens structural integrity, often caused by stress or manufacturing errors.

- Corrosion: Degrades metal over time, leading to holes and wall thinning.

- Scratches: Can lead to stress concentration and eventual cracks or corrosion.

- Pitting: Small, deep depressions that trap contaminants and weaken the metal.

- Burrs: Rough edges formed during cutting or machining that can impede flow.

- Scale & Deposits: Build-ups inside tubes that restrict flow or cause corrosion.

- Welding Defects: Incomplete welds or porosity that can reduce tube strength.

Challenges in Metal Tube Inner Surface Inspection

Inspecting the inner surface of metal tubes is a highly specialized task. The very nature of metal tubes introduces a unique set of challenges that conventional inspection methods simply cannot overcome.

1. Extremely Small Inner Diameters (ID)

Many metal tubes used in aerospace, medical, and automotive applications feature inner diameters smaller than 50 mm, making internal access inherently difficult. When the diameter drops below 10 mm, the challenge intensifies.

2. Long and Narrow Tube Structures

Metal tubes can extend several meters in length, and inspecting their entire inner surface demands precise, consistent movement of the imaging system. Any variation in speed or angle can distort the image or miss a defect.

3. Micron-Level Defect Sensitivity

Defects like scratches, pitting, micro-cracks, and corrosion may exist at a scale smaller than 10 microns, yet they can critically impact tube performance and safety. Capturing these flaws are highly challenging tasks.

4. Highly Reflective Metal Surfaces

The shiny, polished interiors of metal tubes pose another obstacle: light reflection and glare. These optical interferences can obscure defects or create false positives.

How Customized Machine Vision AOI Enabling High-Accuracy Inspection of Metal Tube Inner Surfaces

In high-precision industries where safety, performance, and compliance are non-negotiable, the inspection of internal metal tube surfaces must be exacting. Machine Vision AOI, combined with customized imaging systems and intelligent automation, enables unparalleled accuracy in detecting micro-defects—even in the most confined and reflective environments. Below are the core technologies that drive this innovation:

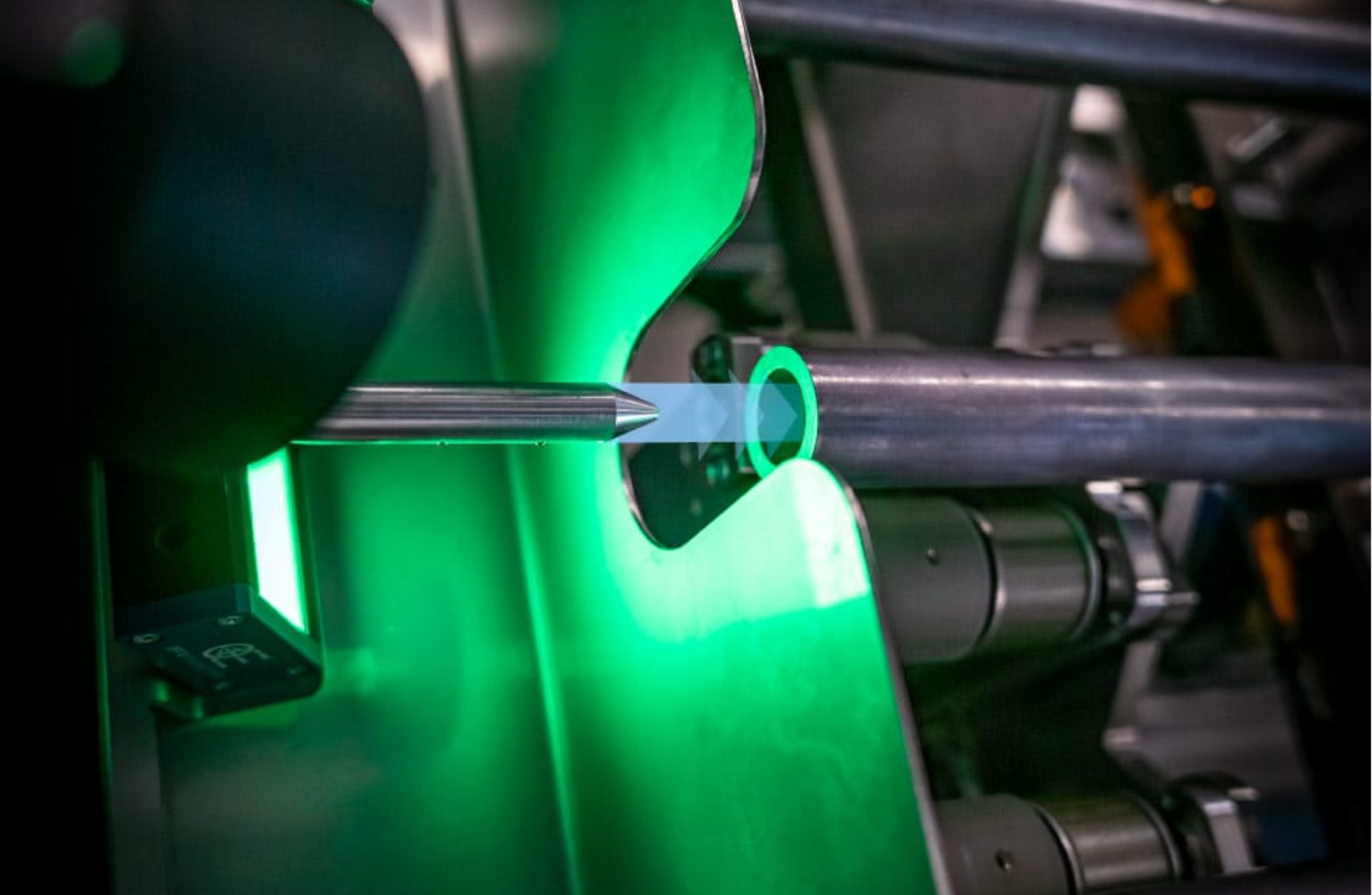

1. Customized Imaging Devices for Tube Geometry and ID Constraints

Reliable inner surface inspection begins with choosing imaging solutions engineered to match the tube’s internal diameter, length, and defect resolution requirements.

Machine Vision Cameras

- Optimal for tubes with inner diameters larger than 40–45 mm.

- Provide customizable optics and resolutions, enabling detailed imaging across a broad range of applications.

- When combined with precision-controlled lighting, these cameras excel at detecting defects on highly reflective metal surfaces.

Miniature Cameras

- Essential for inspecting tubes with inner diameters under 20 mm, especially those below 10 mm.

- These compact, high-resolution cameras are specifically engineered to navigate constrained, curved, or complex internal geometries while maintaining high image quality.

- Perfect for medical devices, fuel lines, and aerospace tubing, where space and precision are critical.

2. Optimized Lighting Systems for High-Fidelity Image Capture

High-quality imaging is only possible with lighting systems designed to enhance contrast and eliminate interference from reflective surfaces.

- High-Intensity Illumination: Delivers the light output required for small, enclosed environments, allowing sensors to reveal fine surface details.

- Adjustable Lighting Angles: Mitigates glare from polished or chromed tube interiors, ensuring maximum visibility of micro-defects.

- Compact Integration: Lighting systems are miniaturized and precisely aligned to fit alongside imaging devices within tight inner diameters without compromising coverage.

3. AI-Powered Defect Detection with Machine Vision Intelligence

At the heart of this inspection solution is Machine Vision AI—the intelligence layer that transforms image data into actionable insights.

Live Vision AI by Intelgic

- Real-Time Image Processing: Analyzes high-speed visual data streams to detect and classify cracks, pitting, corrosion, delamination, and burrs—even down to micron-level tolerances.

- Adaptive Machine Learning Models: Continuously trained with domain-specific datasets to evolve with new materials, defect types, and surface finishes.

- Universal Camera Compatibility: Works seamlessly with USB 3.0, GigE, and MIPI camera interfaces, enabling plug-and-play functionality with a range of imaging systems.

- Automation-Ready Architecture: Fully integrates with robotic systems and motion controllers, delivering end-to-end inspection, defect mapping, and reporting—without manual intervention.

4. Customized Electromechanical Systems for Automated Tube Scanning

High-resolution inspection demands not only sharp imaging and intelligent software but also precise mechanical execution.

- Precision-Controlled Movement: Robotic arms, linear actuators, or guide rails move imaging modules at a uniform speed and alignment, preserving image consistency across the full tube length.

- Scalable Configurations: Electromechanical platforms are designed to adapt to varying tube lengths, diameters, and structural conditions, making them ideal for deployment across aerospace, oil & gas, medical, and automotive sectors.

- Fully Synchronized System Integration: From data acquisition to AI analysis and defect reporting, the entire workflow is synchronized and centrally managed, ensuring efficient and traceable inspection outcomes.

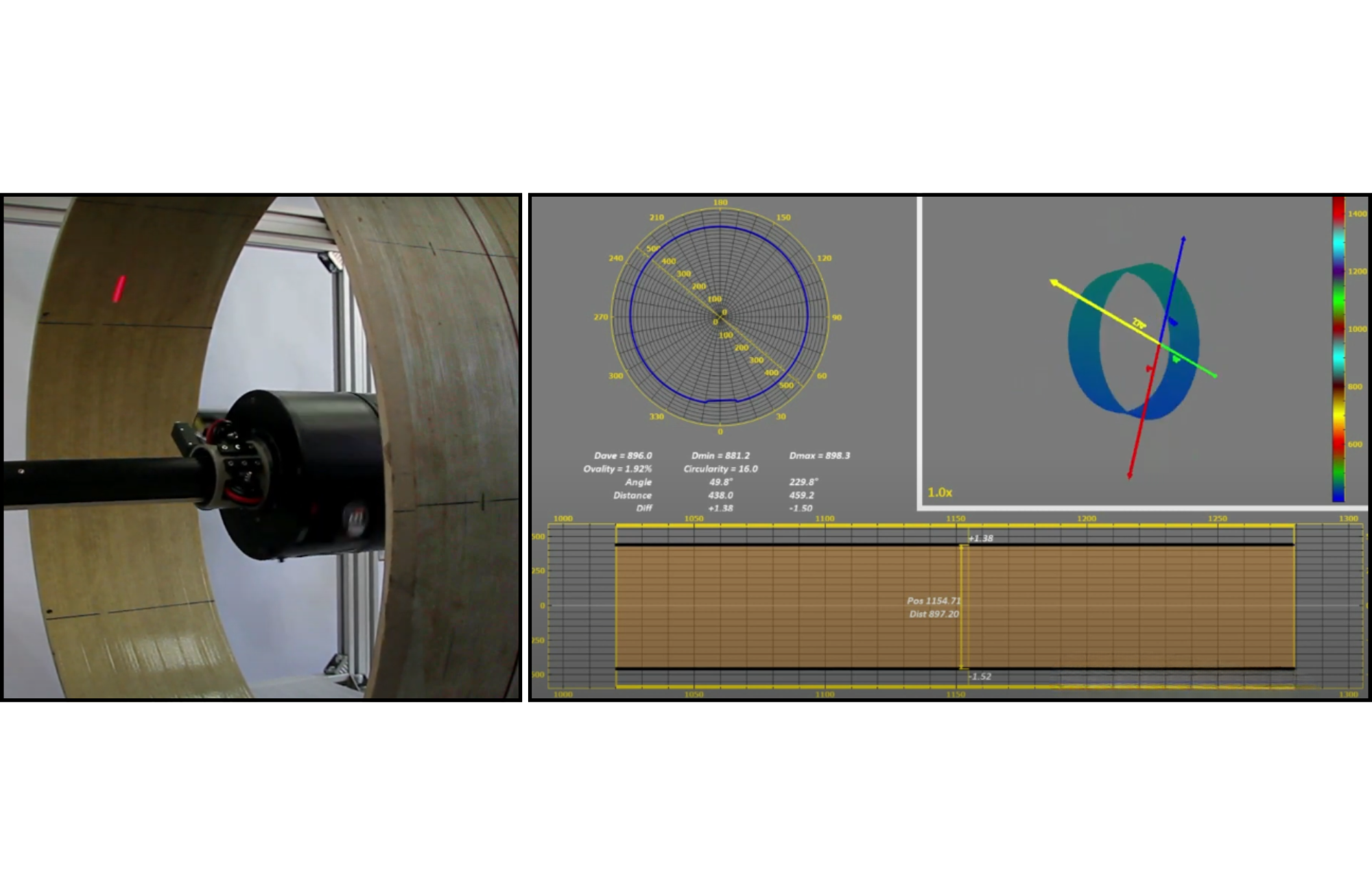

Inspection Workflow: Step-by-Step Process for Metal Tube Inner Surface Analysis

Effective inner wall inspection of metal tubes requires precision across every stage—from calibration to final reporting. The following step-by-step workflow outlines how advanced imaging, motion control, and AI-powered software work in harmony to deliver reliable and high-resolution inspection results.

1. Calibration and Optimization

Before initiating inspection, the system undergoes meticulous calibration to ensure consistent image quality and mechanical precision.

- Camera Alignment: Position the imaging hardware to fully cover the internal circumference of the tube.

- Lighting Calibration: Adjust lighting intensity and angles to eliminate glare, enhance surface contrast, and reveal subtle defects.

- Motion Tuning: Fine-tune parameters for speed and linearity of motion systems to maintain image clarity throughout the inspection pass.

2. High-Resolution Image Acquisition

The imaging device travels the full length of the metal tube, collecting detailed internal visuals.

- Dynamic Scanning: Sensors capture high-resolution line-scan images or video in real time while the device moves through the tube.

- Synchronized Motion: Motion systems ensure smooth and stable traversal, avoiding image distortion or skipped areas.

3. Real-Time AI-Driven Defect Detection

Captured data is immediately analyzed by Live Vision AI, delivering fast and accurate defect identification.

- Micron-Level Analysis: The software detects minute flaws such as cracks, corrosion, burrs, pitting, or weld irregularities—often under 10 µm.

- Defect Classification: AI models categorize defects by type, size, and severity, enabling faster decision-making.

- Adaptive Intelligence: The AI continually improves through training with material-specific data, increasing accuracy with every inspection cycle.

4. Automated Reporting & Quality Documentation

Inspection concludes with comprehensive reporting and visual documentation for traceability and compliance.

- Defect Localization: Precise maps indicate where each defect is located along the tube’s length.

- Image-Based Reports: High-resolution images and defect classifications are compiled for QA teams.

- Data Integration: Reports can be exported and connected with ERP or MES platforms for audit readiness and continuous improvement workflows.

Applications Across Industries

Aerospace

Inspect fuel and hydraulic lines for cracks, corrosion, or blockages, ensuring aircraft safety and reliability.

Automotive

Examine exhaust systems, brake lines, and turbo tubing for defects, ensuring performance and safety.

Oil & Gas

Detect pitting, corrosion, and scale inside pipelines and casings to prevent failures and maintain efficiency.

Medical Devices

Ensure flaw-free surgical-grade tubing and implants, safeguarding patient safety and compliance with standards.

Heavy Machinery

Verify the integrity of high-pressure hydraulic systems, preventing malfunctions and minimizing downtime.

Benefits of Customized Machine Vision AOI for Metal Tube Inner Surface Inspection

Customized Machine Vision Automated Optical Inspection (AOI) systems provide tailored solutions that enhance the inspection of metal tube inner surfaces across various industries. By combining high-resolution imaging with AI-powered defect detection, these systems offer several distinct advantages for improving quality control and operational efficiency. Here are the key benefits of using customized Machine Vision AOI systems:

1. Precision Tailored to Specific Needs

Customized Machine Vision AOI systems can be designed to address the unique requirements of different tube dimensions and industry standards. Whether it’s small-diameter tubes in the medical sector or large industrial tubing, the system can be configured to ensure micron-level defect detection, capturing even the smallest imperfections such as cracks, corrosion, and pitting.

2. Enhanced Inspection Speed

With specialized configurations optimized for specific applications, customized AOI systems significantly accelerate inspection processes. By automating defect detection and analysis, these systems speed up production cycles, enhancing throughput while maintaining high-quality standards.

3. Consistent, Error-Free Results

Customized Machine Vision AOI eliminates human error from the inspection process. The system delivers consistent, repeatable results, ensuring that every tube undergoes the same rigorous analysis without the variability that comes with manual inspection, even during extended shifts or complex conditions.

4. Cost Efficiency

Automating the inspection process through customized AOI solutions leads to substantial cost savings by reducing the need for manual labor. Additionally, the early detection of defects helps prevent costly rework, product failures, or recalls, resulting in long-term savings for manufacturers.

5. Real-Time Defect Detection and Immediate Feedback

AI-driven analysis in customized AOI systems offers real-time defect detection and classification. This enables immediate corrective actions, preventing defects from advancing through production lines and reducing downtime, thus improving overall operational efficiency.

6. Scalable and Flexible for Different Applications

Customized AOI systems are scalable, meaning they can adapt to varying production volumes and tube sizes. Whether inspecting long, narrow tubes in the aerospace sector or large industrial pipes in oil and gas applications, these systems provide flexible solutions that grow with manufacturing needs.

7. Detailed Data Collection and Reporting

Customized Machine Vision AOI systems collect detailed data on every tube inspected, including defect type, location, and severity. This valuable information is automatically compiled into comprehensive reports that aid in quality control, continuous improvement, and regulatory compliance.

Intelgic’s Live Vision AI : The Ideal Solution for Metal Tube Inner Surface Inspection

Intelgic’s Live Vision AI offers a comprehensive, end-to-end solution designed to elevate the quality and efficiency of metal tube inner surface inspections across industries. Here’s why it stands out as the ideal choice for your inspection needs:

1. Complete End-to-End System

Intelgic’s Live Vision AI integrates seamlessly with customized imaging hardware, advanced AI software, and automation systems. This all-in-one solution ensures a smooth workflow from image capture through to real-time analysis and reporting, simplifying the inspection process and eliminating the need for disparate systems.

2. Micron-Level Defect Detection

Live Vision AI is engineered for the highest levels of accuracy. It can detect even the smallest imperfections, such as cracks, corrosion, and burrs, down to the micron level. This level of precision ensures that no flaw goes unnoticed, safeguarding the integrity of every tube and preventing costly failures.

3. Industry Flexibility

Whether you’re in aerospace, automotive, oil & gas, healthcare, or any other sector, Live Vision AI is adaptable to a wide range of applications. Its versatile technology makes it suitable for inspecting various tube types, including those used in critical environments such as medical implants or aerospace fuel lines.

4. Customization to Your Manufacturing Needs

Every manufacturing process is unique. Intelgic’s Live Vision AI can be tailored to your specific requirements, including tube size, defect type, production volume, and environmental conditions. This flexibility ensures that the system delivers the best performance for your particular inspection challenges, optimizing both accuracy and throughput.

5. Real-Time Results

With Live Vision AI’s real-time defect detection capabilities, you can take immediate corrective action. The system processes data on the fly, alerting operators to defects as soon as they are identified, helping to prevent defective products from reaching later stages in production. This rapid feedback loop accelerates quality assurance, promoting a zero-defect manufacturing process and improving overall production efficiency.

Intelgic’s Live Vision AI is a game-changer in the field of metal tube inner surface inspection, offering unparalleled precision, flexibility, and real-time insights. With its ability to detect even the smallest defects, customize to your needs, and accelerate your quality control process, it’s the ideal solution for industries that demand the highest standards of safety and performance.

Contact Intelgic today to learn more about how Live Vision AI can transform your inspection process and enhance your manufacturing efficiency. Our team is ready to help you implement this cutting-edge technology tailored to your unique needs.