Strobing in Machine Vision: Why It’s Essential and How It Works

Published on: Sep 15, 2025

Written by: Content team, Intelgic

Introduction

In high-speed industrial inspection, capturing sharp and well-illuminated images is a challenge. Products on conveyor belts, rotating shafts, or vibrating machinery can cause motion blur and inconsistent lighting. To overcome these challenges, machine vision systems often use strobing—a technique where light is pulsed in short bursts, synchronized with the camera.

Strobing is not just about “flashing a light.” It is a powerful tool that improves image clarity, contrast, and repeatability while reducing heat and energy consumption.

What Is Strobing?

Strobing refers to pulsing a light source (usually LED) for very short, intense bursts of illumination—typically in the range of microseconds to milliseconds—synchronized with the camera’s exposure.

Instead of keeping the light continuously on, the system only illuminates the object when the camera is actually capturing an image.

In machine vision, strobing has two main purposes:

- Freeze motion – eliminating motion blur in high-speed applications.

Enhance contrast – by controlling timing, duration, and intensity, strobing reveals defects and features more clearly.

Why Do We Need Strobing in Machine Vision?

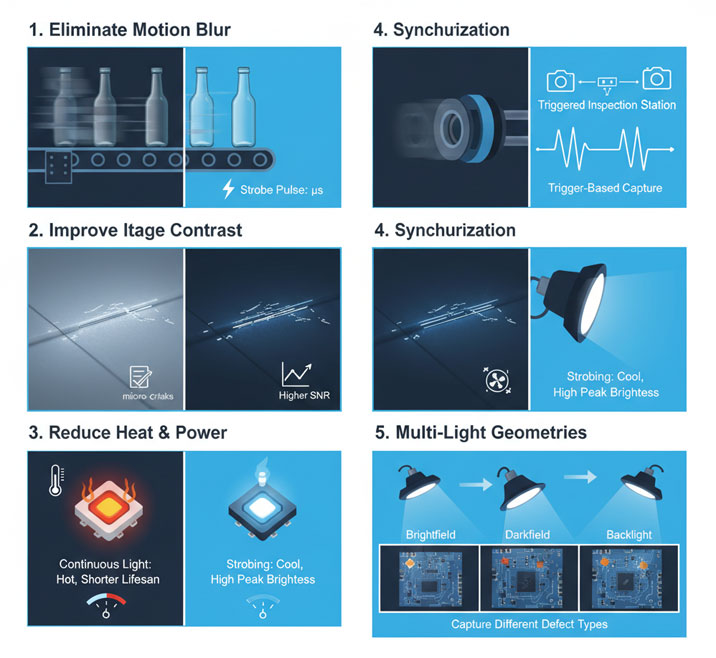

1. Eliminate Motion Blur

- In high-speed production lines (e.g., bottles moving at hundreds per minute), continuous light causes blurred images.

- A strobe pulse lasting a few microseconds “freezes” motion, similar to a fast shutter speed in photography.

2. Improve Image Contrast

- Short, bright pulses create higher signal-to-noise ratios (SNR).

- This increases the visibility of fine defects such as micro-cracks, scratches, or print misalignments.

3. Reduce Heat and Power Consumption

- Continuous high-intensity LEDs generate significant heat, reducing their lifespan.

- With strobing, LEDs are only on for a fraction of time, allowing higher peak brightness without overheating.

4. Synchronization with Fast Processes

- Strobing ensures the camera only captures the object at the correct position (trigger-based inspection).

- Essential for rotating parts, conveyor lines, or intermittent processes.

5. Enable Multi-Light Geometries

- Multiple strobes at different angles (brightfield, darkfield, backlight) can be triggered in sequence.

This allows one system to capture different defect types on the same product in milliseconds.

How Strobing Works

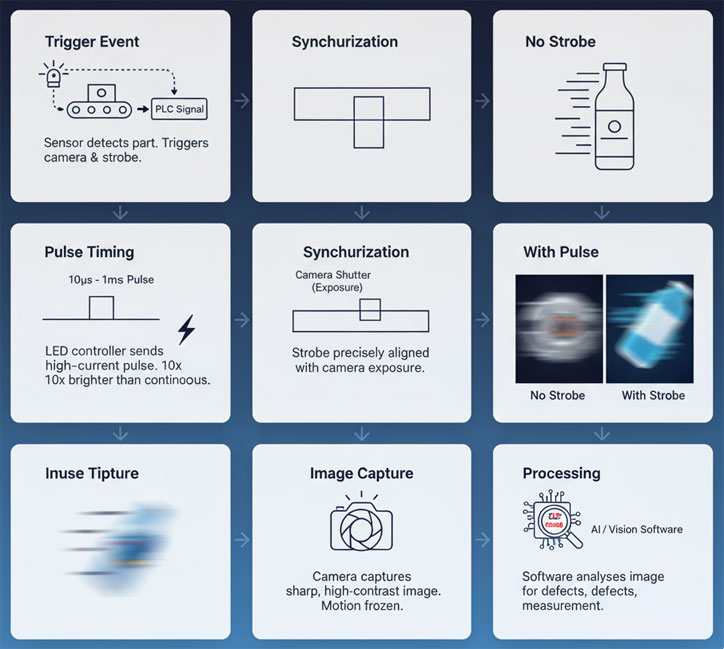

- Trigger Event

- A sensor (e.g., encoder, photoelectric sensor, PLC signal) detects the presence or position of a part.

- This signal triggers both the camera exposure and the strobe light.

- A sensor (e.g., encoder, photoelectric sensor, PLC signal) detects the presence or position of a part.

- Pulse Timing

- The LED light controller delivers a short, high-current pulse to the light source.

- Typical pulse duration: 10 µs to 1 ms.

- The intensity can be 5–10× brighter than continuous mode since duty cycle is low.

- The LED light controller delivers a short, high-current pulse to the light source.

- Synchronization

- The strobe pulse is precisely aligned with the camera’s shutter (global or rolling).

- This ensures maximum light reaches the sensor exactly when the image is taken.

- The strobe pulse is precisely aligned with the camera’s shutter (global or rolling).

- Image Capture

- The camera captures a sharp, high-contrast image with motion effectively frozen.

- The camera captures a sharp, high-contrast image with motion effectively frozen.

- Processing

The image is processed by AI/vision software for defect detection, measurement, or classification.

Example Applications

- PCB Inspection – capturing sharp images of tiny SMDs on moving boards.

- Bottle and Packaging Lines – preventing motion blur in high-speed labeling inspection.

- Automotive Shafts and Gears – imaging rotating shafts at high RPM.

- Textile and Film Inspection – strobing highlights micro-tears in continuous webs.

Pharmaceuticals – inspecting capsules or vials at thousands per minute.

Technical Considerations in Strobing

- Duty Cycle – Ratio of ON time to OFF time. Keeping this low prevents overheating.

- Overdrive Current – LEDs are designed to tolerate short bursts at much higher currents than continuous rating.

- Controller Precision – High-speed LED drivers with µs-level timing accuracy are needed.

- Camera Type – Global shutter cameras work best since they expose all pixels simultaneously.

Jitter – Synchronization accuracy should be within a few microseconds to avoid blur.

Intelgic’s Approach to Strobing

At Intelgic, strobing is an integral part of our custom machine vision systems:

- Programmable LED Controllers – Adjust pulse width, frequency, and intensity per inspection recipe.

- Multi-Geometry Lighting – Switch between darkfield, brightfield, and backlight strobes in a single cycle.

- AI Integration – Intelgic’s Live Vision AI adapts strobing parameters dynamically to maximize defect visibility.

Hardware Longevity – Strobing reduces LED heat stress, extending life of lighting systems.

Conclusion

Strobing is more than just flashing lights—it is a precision illumination technique that enables sharp, high-contrast imaging in machine vision applications. By freezing motion, reducing power consumption, and enhancing defect visibility, strobing has become indispensable for high-speed, micron-level quality inspection.

With Intelgic’s AI-driven machine vision solutions, manufacturers can harness the power of strobing to achieve zero-defect manufacturing even in the most demanding environments.