Live Vision – Intelgic’s Machine Vision AI Software for Visual Defect Detection

Published on: Aug 01, 2025

Written by: Content team, Intelgic

Live Vision is Intelgic’s proprietary machine vision AI platform, purpose-built to transform manual inspection processes into fully automated, intelligent, and traceable quality control systems. Designed for high-performance visual inspection across a wide range of automotive parts, Live Vision combines real-time AI analysis, high-speed imaging integration, and cloud-based analytics into a single comprehensive solution.

Core Capabilities and Features

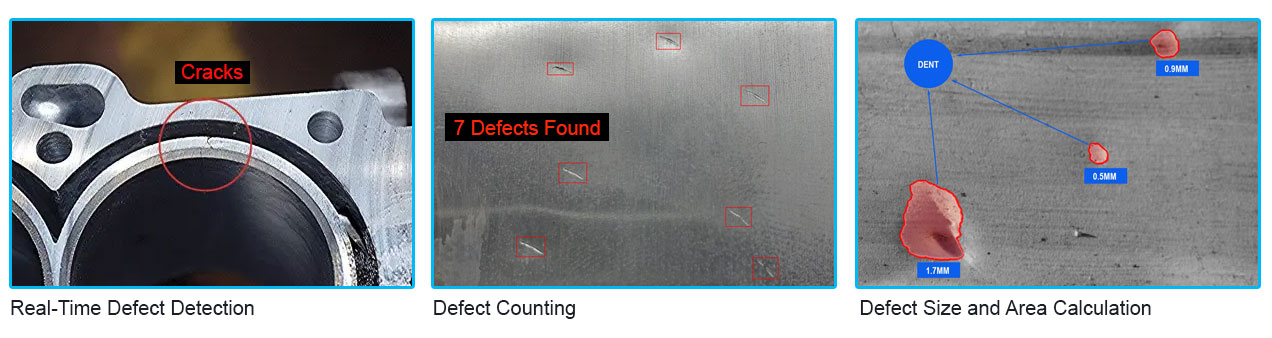

Real-Time Defect Detection

- Detects a wide range of visual defects including scratches, dents, cracks, pinholes, surface contamination, discoloration, smudges, and assembly errors.

- Trained using deep learning models to distinguish between real defects and acceptable surface variations.

Defect Counting

- Automatically counts the number of defects on each part or surface.

- Useful for defect density analysis and threshold-based rejection.

Defect Size and Area Calculation

- Measures each defect’s size in pixels or calibrated millimeters.

- Supports severity scoring and classification (minor vs. major defects).

- Enables correlation with quality standards like IPC, ISO, or OEM-specific guidelines.

Acceptance Criteria & Pass/Fail Logic

- Customizable rules engine allows you to define:

- Minimum and maximum defect size

- Acceptable number of defects per zone or part

- Specific exclusion zones or priority zones

- Minimum and maximum defect size

- Live Vision applies these rules in real time to classify each inspected part as PASS or FAIL.

Alert Generation

- Triggers instant visual or audio alarms when a failure is detected.

- Can send notifications to PLC, HMI, MES, or email/SMS based on severity.

- Supports escalation workflows when defect trends cross defined thresholds.

Comprehensive Inspection Reports

- Automatically generates detailed reports for each part or batch including:

- Part ID or barcode

- Timestamp

- Defect type, location, size, and image snapshot

- Final decision (PASS/FAIL)

- Part ID or barcode

- Reports can be exported as PDF, Excel, or JSON formats.

Digital Inspection Certificates

- Produces digital certificates summarizing inspection results for:

- Customer validation

- OEM audits

- Internal QA documentation

- Customer validation

Includes AI classification scores, annotated images, and compliance notes.

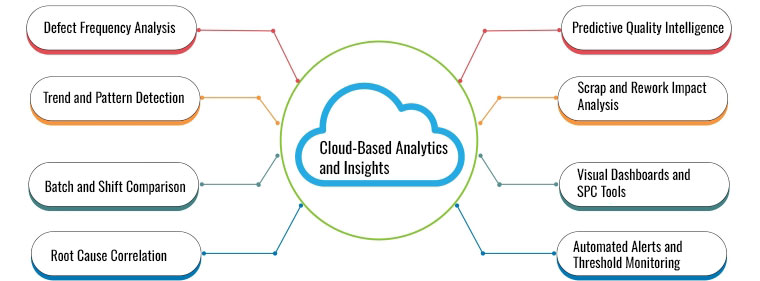

Cloud-Based Analytics and Insights

Live Vision comes with an optional cloud analytics module that aggregates inspection data across parts, lines, and factories to provide advanced quality insights:

Defect Frequency Analysis

- Identifies the most common defect types by category, model, or production line.

- Helps prioritize quality improvement efforts.

Trend and Pattern Detection

- Tracks how specific defect types evolve over time.

- Highlights seasonal, shift-based, or machine-specific issues.

- Detects emerging defect patterns using predictive analytics.

Batch and Shift Comparison

- Compares quality metrics across different production batches, shifts, or operator teams.

- Useful for evaluating process improvements and operator training effectiveness.

Root Cause Correlation

- Integrates with process parameters (e.g., temperature, humidity, supplier lot, machine ID) to identify potential causes of recurring defects.

- Supports Six Sigma, DMAIC, and lean quality initiatives.

Predictive Quality Intelligence

- Uses AI models to forecast the likelihood of defect occurrence based on historical trends.

- Recommends proactive interventions before defect rates spike.

Scrap and Rework Impact Analysis

- Analyzes the financial and operational impact of defects.

- Calculates projected savings from defect reduction initiatives.

Visual Dashboards and SPC Tools

- Interactive dashboards with:

- Defect heatmaps

- Pareto charts

- Control charts (X-bar, R-chart)

- CPK and PPK analysis

- Defect heatmaps

- Configurable KPIs for quality managers and production supervisors.

Automated Alerts and Threshold Monitoring

- Set custom thresholds for specific defect types or rates.

- Get real-time alerts when production drifts from acceptable quality limits.

Live Vision: Driving Intelligent Quality Control

With its comprehensive defect detection capabilities and powerful analytics suite, Live Vision shifts the focus from reactive quality checks to proactive quality assurance. It not only ensures that every part meets customer-defined standards but also empowers manufacturers to identify, prevent, and eliminate quality issues at their root.

Whether you’re inspecting alloy wheels, instrument panels, welded components, or transparent covers, Live Vision delivers consistent, high-precision results at scale—every shift, every line, every part.