Lighting Geometry in Machine Vision Systems: A Complete Guide

Published on: Sep 15, 2025

Written by: Content team, Intelgic

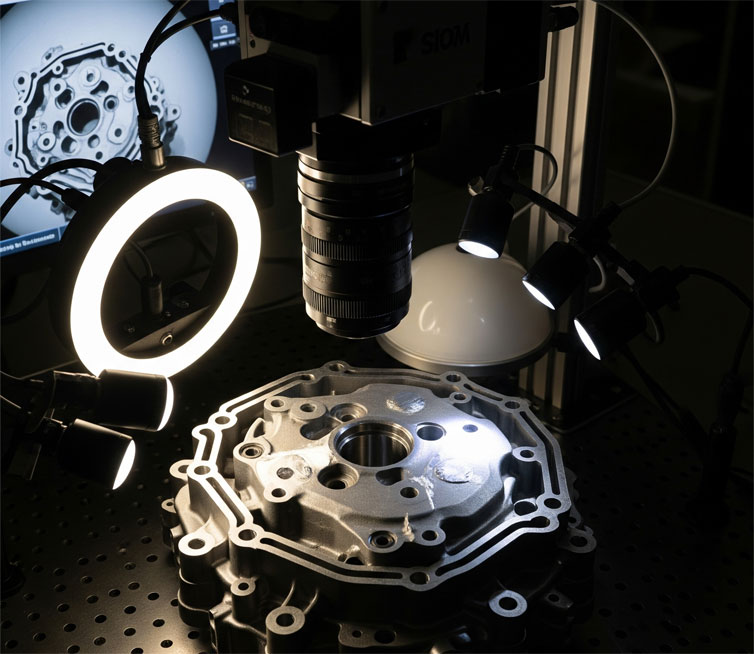

Setup the Right lights with Perfect Geometry for Detailed Imaging

In machine vision, the camera and lens often get most of the attention. However, lighting geometry—the way light is directed onto a part—plays an equally critical role in determining inspection accuracy. The correct lighting setup can reveal surface defects invisible under ambient light, while the wrong geometry can hide crucial details or produce misleading reflections.

At Intelgic, lighting design is a core part of every automated optical inspection (AOI) system we build. By combining advanced optics, specialized lighting sources, and AI-driven vision software, we tailor inspection solutions for any material, shape, or finish.

Why Lighting Geometry Matters

Machine vision systems rely on contrast. Cameras don’t inherently “see defects”—they detect differences in brightness, color, or texture. The geometry of lighting determines:

- Which features are enhanced (scratches, edges, textures, coatings, contaminants).

- Which features are suppressed (glare, background noise, irrelevant patterns).

- How repeatable results are across different production conditions.

In other words, lighting geometry is about controlling the path of light between source, object, and sensor to maximize useful information.

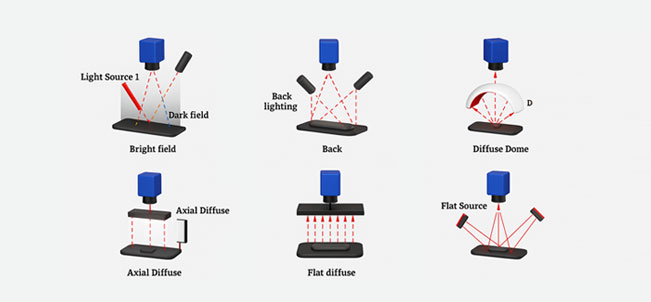

Common Lighting Geometries in Machine Vision

1. Brightfield Lighting

- Setup: Light is directed onto the part from the same side as the camera, usually at an angle.

- Best For: Detecting surface features such as scratches, dents, or raised defects.

- Example: Inspecting painted metal sheets for pinholes or cracks.

2. Darkfield Lighting

- Setup: Light is projected at a very low angle (grazing incidence). The camera only sees scattered light from edges, particles, or surface defects.

- Best For: Enhancing small surface imperfections like dust, burrs, or micro-scratches.

- Example: Inspection of glass or polished metal.

3. Backlighting

- Setup: Light source is placed behind the object, opposite to the camera.

- Best For: Silhouette analysis, dimensional measurements, edge detection, and transparency evaluation.

- Example: Checking lens diameter or detecting gaps in transparent films.

4. Coaxial Lighting

- Setup: Uses a beam-splitter to project light directly along the camera’s axis.

- Best For: Creating uniform illumination on flat, reflective surfaces.

- Example: Detecting print defects on PCBs or etched markings on silicon wafers.

5. Diffuse Dome Lighting

- Setup: Light is scattered inside a dome, creating highly uniform illumination from all angles.

- Best For: Eliminating glare and reflections on shiny or curved surfaces.

- Example: Inspecting curved plastic parts or pharmaceutical blister packs.

6. Structured Lighting (Laser/Pattern Projection)

- Setup: Projects lines or patterns onto the object, captured by the camera for 3D reconstruction.

- Best For: Surface profiling, height measurement, or detecting warpage.

Example: Measuring flatness of ceramic plates or curvature of lenses.

Factors Affecting Lighting Geometry Design

When Intelgic designs lighting for AOI systems, we consider:

- Surface Properties – Reflective, matte, transparent, or translucent surfaces demand very different lighting geometries.

- Part Geometry – Flat, curved, cylindrical, or complex 3D shapes influence how light interacts with surfaces.

- Defect Type – Micro-scratches need darkfield, dimensional checks need backlighting, and print inspection may require coaxial.

- Production Environment – Ambient light, vibrations, dust, or temperature shifts can alter imaging results.

Throughput & Speed – High-speed lines (e.g., steel coils at 55 MPM) may require line-scan lighting with precise synchronization.

Practical Applications

- Metal Surface Inspection: Low-angle darkfield lighting highlights cracks, scratches, and pinholes.

- Glass & Transparent Material Inspection: Backlighting or coaxial lighting suppresses reflections and enhances defect visibility.

- Automotive Part Inspection: Dome lighting eliminates hot spots on curved plastic or painted parts.

Medical Device Inspection: Multi-angle lighting geometries detect defects as small as 10 µm on stents, syringes, or prosthetics.

Intelgic’s Approach to Lighting Geometry

At Intelgic, we don’t believe in off-the-shelf lighting setups. Each inspection challenge requires custom-designed lighting geometry that may combine multiple illumination methods. Our systems often integrate:

- Dynamic lighting modules – switching between brightfield, darkfield, and backlight based on inspection stage.

- Robotic motion systems – moving lights and cameras around complex parts for full 360° inspection.

- AI-driven adaptive lighting – software that adjusts illumination in real time to maintain consistent results.

This flexibility ensures we can inspect any material, any defect, under any condition—a cornerstone of our vision for Zero Defect Manufacturing.

Conclusion

Lighting geometry is the foundation of successful machine vision inspection. The right geometry turns invisible defects into high-contrast features, enabling precise detection, measurement, and classification.

By combining advanced lighting design with Intelgic’s Live Vision AI software, manufacturers can move beyond manual inspection toward fully automated, traceable, and error-free quality control.

FAQ

Q1: Can a single lighting geometry work for all inspections?

No. Most complex products require a combination of lighting geometries to detect different defect types.

Q2: How does Intelgic handle transparent or reflective surfaces?

We use specialized setups like low-angle lights, backlights, or dome lights to reduce glare and highlight defects.

Q3: Can lighting be changed dynamically during inspection?

Yes. Intelgic’s systems often integrate programmable lighting modules that switch geometries in real time.