Length and Width Measurement of Wooden Panels and Metal Sheets with Machine Vision AOI

Published on: Apr 28, 2025

Written by: Content team, Intelgic

Length and Width Measurement of Wooden Panels and Metal Sheets with Machine Vision AOI

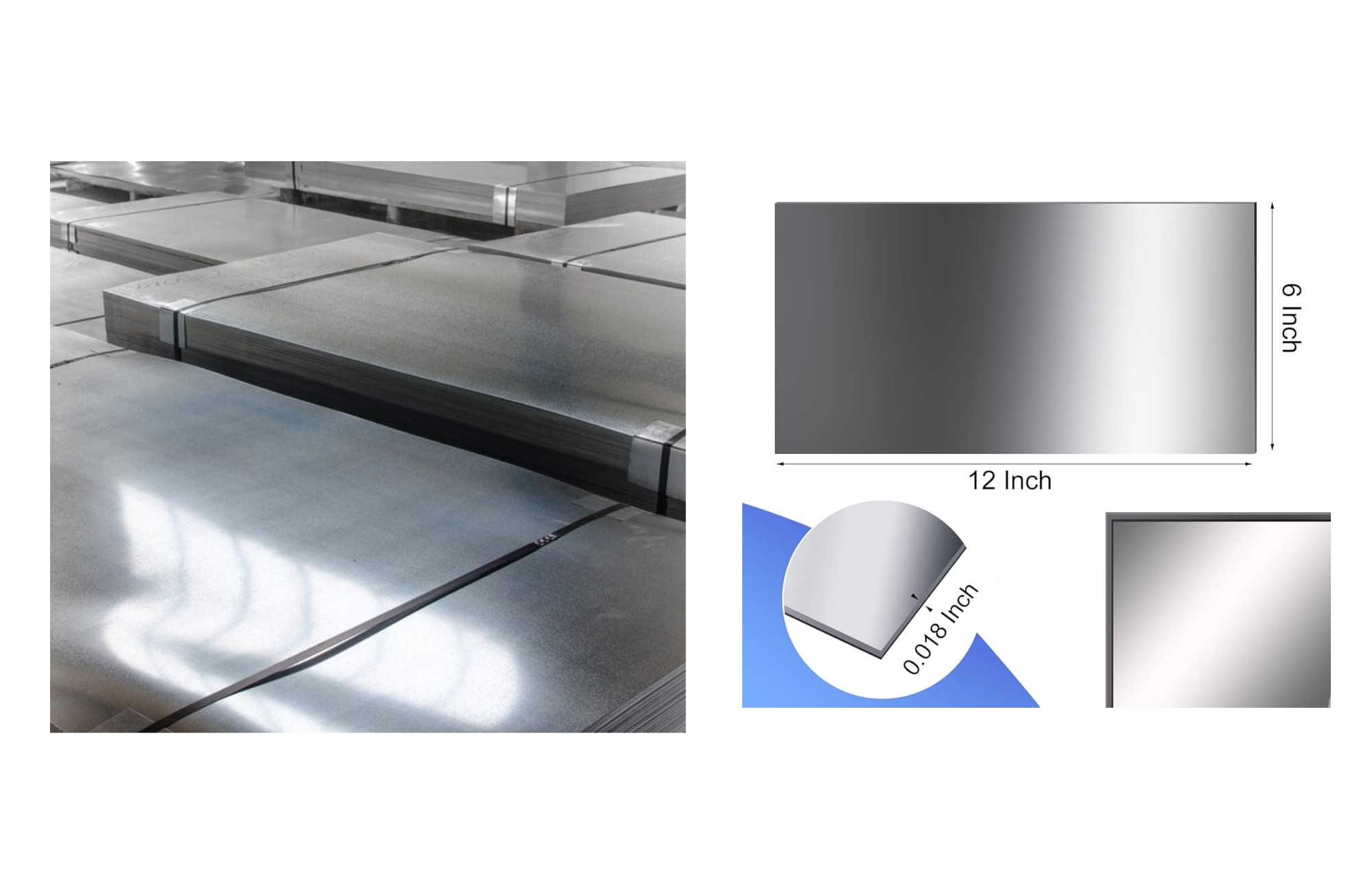

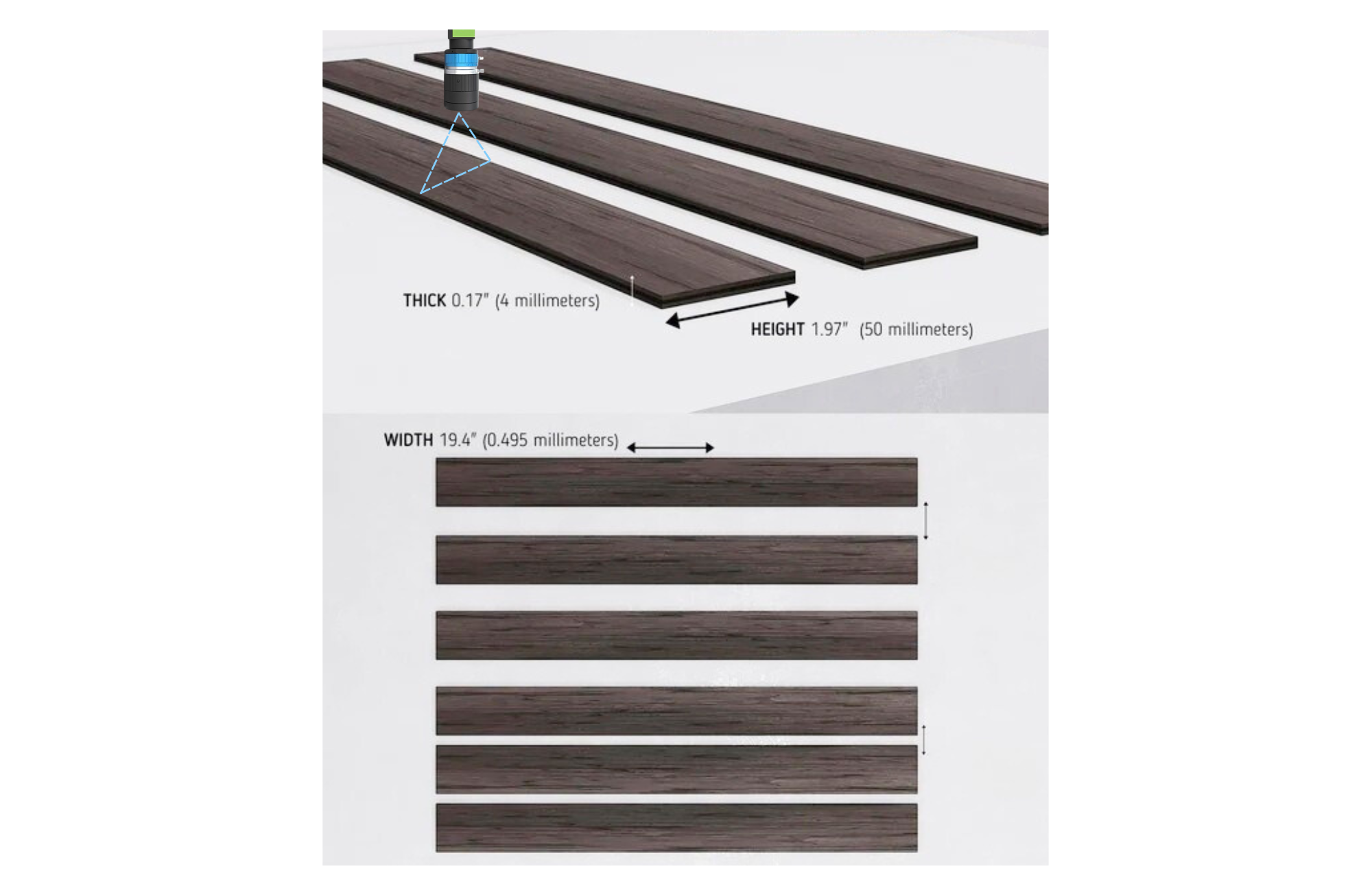

In the highly competitive manufacturing landscape, the demand for precision, consistency, and speed is greater than ever. Accurate height and width measurement of wooden panels and metal sheets is critical across industries such as furniture manufacturing, construction, automotive, aerospace, and industrial fabrication. Traditional measurement techniques, reliant on manual inspection or basic sensors, are increasingly inadequate for today’s high-speed, high-accuracy requirements.

Machine Vision Automated Optical Inspection (AOI) offers a transformative solution — delivering real-time, highly precise measurements that enable manufacturers to meet exacting specifications, optimize quality assurance, and enhance operational efficiency.

Challenges in Industrial Measurement of Panels and Sheets

Measuring large, fast-moving panels and sheets presents distinct technical challenges:

- High-Speed Production Lines: Panels often travel at significant speeds, making manual or conventional optical inspection methods impractical without causing production delays.

- Vibration and Conveyor Movement: Mechanical vibrations and slight shifts during transportation can interfere with stable measurements.

- Surface Variability: Wooden panels often exhibit natural grain and color inconsistencies, while metal sheets may cause glare and reflection, both of which complicate accurate edge detection.

- Precise Edge Identification: Consistent and reliable edge detection is critical for accurate dimensional measurement but can be difficult across various surface textures and environmental lighting conditions.

- Stringent Tolerance Requirements:Modern industries demand extremely precise measurements, necessitating systems capable of sub-millimeter accuracy to ensure product conformity.

Line Scan Cameras and Backlighting: The Industrial Standard for High-Speed Measurement

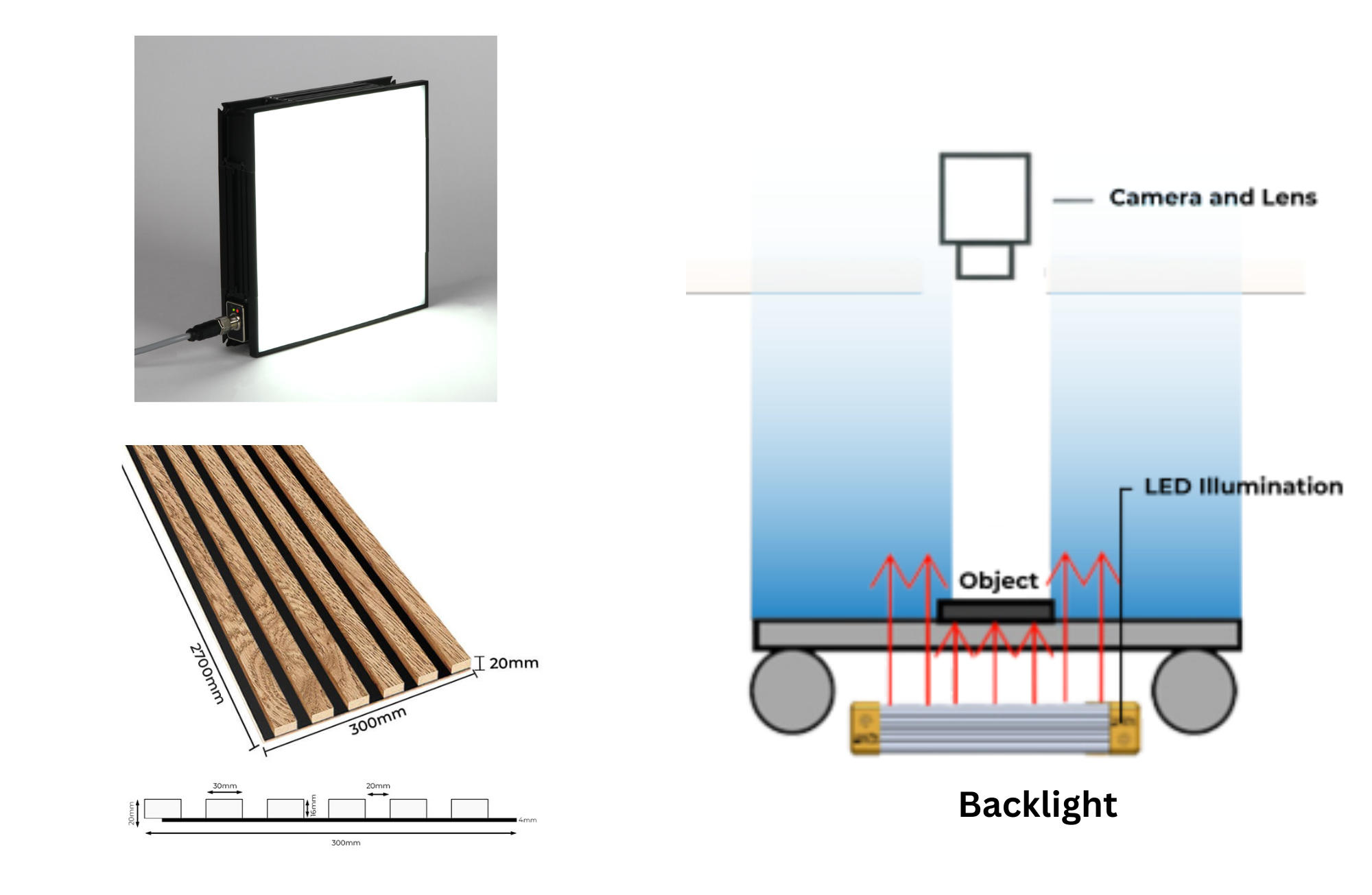

To meet the demands of modern manufacturing environments, line scan cameras combined with backlighting techniques have become the gold standard for high-speed, precision measurement.

Unlike area scan cameras, which capture an entire frame at once, line scan cameras capture one line of pixels at a time. As the panel or sheet moves past the camera, it continuously assembles a full, high-resolution image, making it ideally suited for applications involving constant motion.

Backlighting plays a crucial role by illuminating the panel from behind, creating a sharp, high-contrast silhouette. This enables precise detection of the material’s true edges, unaffected by surface colors, textures, or reflections. The resulting high-contrast images allow real-time AI algorithms to measure dimensions with unparalleled accuracy.

This configuration ensures:

- Clear edge demarcation regardless of surface finish

- Stability of measurement despite vibrations

Consistent performance at conveyor speeds exceeding conventional measurement capabilities

Real-Time AI-Driven Measurement Software

The integration of real-time AI software elevates machine vision AOI systems to the next level, ensuring robust performance in variable industrial environments. AI models are trained on diverse datasets to:

- Detect panel edges with sub-millimeter precision even under challenging conditions such as dirt, minor damage, or lighting fluctuations.

- Dynamically compensate for vibration, conveyor shifts, and slight misalignments.

- Continuously monitor measurement trends to predict quality deviations before they become critical.

- Automatically adjust processing parameters in real-time to maintain measurement consistency.

With AI at the core, manufacturers achieve consistent height and width measurements well within the stringent ±0.3 mm to ±0.5 mm tolerance range, dramatically improving production quality and reducing scrap rates.

Detailed Inspection Process

The typical measurement and inspection workflow includes:

1. Detection of Material Arrival

The process initiates with highly responsive sensors strategically placed along the production line. These sensors detect the presence of a panel or sheet as it approaches the inspection station. Upon detection, a trigger signal is sent to activate the imaging and measurement sequence, ensuring precise synchronization with the material's movement and avoiding any inspection delay.

2. Backlighting

Positioned behind the moving panel or sheet, the backlight floods the material with uniform illumination. This setup creates a sharp, high-contrast silhouette of the material’s profile, eliminating the effects of surface textures, color variations, and reflections. The clear silhouette ensures that the machine vision system captures the true edges of the material with maximum clarity.

3. Continuous Image Acquisition

As the panel or sheet moves through the inspection area, line scan cameras positioned above or beside the conveyor system continuously capture narrow, high-resolution lines of image data. These images are compiled line-by-line to construct a complete and highly detailed representation of the material’s dimensions in real time. The line scan technology enables uninterrupted imaging at high production speeds without any loss of resolution or detail.

4. Real-Time Edge Analysis

Advanced AI algorithms process the live image data to perform precise edge detection. The AI model analyzes the silhouette to identify the exact boundaries of the panel or sheet, compensating dynamically for any minor vibrations, material shifts, or inconsistencies. The algorithms ensure robust detection even in challenging conditions such as surface damage, dust, or lighting variations.

5. Dimensional Calculation

Once the edges are accurately mapped, the system performs dimensional calculations. Width and height are determined by translating the pixel measurements into real-world units using pre-calibrated scaling factors. The calibration ensures that the calculated dimensions reflect the true physical measurements of the material, achieving high accuracy necessary for demanding industrial tolerances.

6. Tolerance Evaluation

The measured dimensions are then compared against predefined tolerance thresholds set according to production specifications. The system evaluates whether the width and height fall within the acceptable range. This evaluation occurs instantaneously, ensuring no disruption to the production flow.

7. Automatic Decision Making

Based on the tolerance evaluation, the system makes an immediate decision. Conforming products are allowed to continue down the line, while non-conforming products — those falling outside the allowable dimensional range — are automatically flagged. Depending on the system setup, flagged products can be diverted to a rejection station, marked for further inspection, or halted for corrective action.

8. Data Logging and Reporting

Every measurement and inspection outcome is logged into a centralized database. Comprehensive data records, including dimensional values, pass/fail results, timestamps, and material identifiers, are archived for traceability. Real-time dashboards and periodic reports allow quality engineers and production managers to monitor performance trends, perform root cause analysis, and continuously refine production processes.

Advantages of Machine Vision AOI Systems for Panel and sheet Measurement

The adoption of AI-enabled Machine Vision AOI systems provides manufacturers with significant operational and strategic advantages:

- High-Speed Inspection: Supports production speeds without bottlenecks.

- Exceptional Accuracy and Repeatability: Maintains measurement precision even under dynamic operating conditions.

- Reduced Labor Costs: Minimizes reliance on manual inspection and the risk of human error.

- Real-Time Quality Monitoring: Immediate feedback enables proactive quality control.

- Scalability and Flexibility: Easily adaptable to a range of product sizes, shapes, and material types.

- Comprehensive Data Collection: Enables advanced analytics for process optimization, predictive maintenance, and regulatory compliance.

How Intelgic Leads the Industry

At the forefront of this technological evolution is Intelgic, offering state-of-the-art solutions tailored for industrial measurement and inspection.

Intelgic's Key Differentiators:

- AI-Driven Edge Detection and Adaptive Learning: Intelgic’s AI models self-optimize based on material variations, ensuring continuous measurement reliability.

- High-Speed, High-Accuracy Integration: Intelgic's systems seamlessly operate on production lines running at elevated speeds while maintaining sub-millimeter measurement precision.

- Customized Backlighting and Imaging Solutions: Tailored lighting and camera configurations maximize contrast and accuracy for specific applications.

- Advanced User Interfaces: Real-time dashboards and analytics empower operators and quality engineers with actionable insights.

- Flexible Tolerance Management: Tolerances can be easily configured for different products, maintaining agility in dynamic production environments.

- Comprehensive Service and Support: From consultation and system design to deployment, training, and after-sales support, Intelgic partners with clients to ensure maximum operational value.

Conclusion

As the demand for tighter tolerances, higher throughput, and zero-defect manufacturing grows, precision measurement systems become non-negotiable. Machine Vision AOI systems, powered by line scan cameras, advanced backlighting, and real-time AI software, offer manufacturers an unparalleled competitive advantage.

Intelgic stands at the vanguard of this technological transformation, delivering robust, scalable, and intelligent solutions that redefine quality assurance for wooden panel and metal sheet manufacturers. By partnering with Intelgic, industrial leaders can achieve superior accuracy, greater efficiency, and elevated customer satisfaction — essential attributes for success in the modern manufacturing era.