AI-Powered Internal Cylinder Inspection Using Boroscopic Cameras and Vision Software

Published on: Jul 15, 2025

Written by: Team Intelgic

Introduction

Industrial gas cylinders—used to store gases like oxygen, hydrogen, nitrogen, and other hazardous or high-pressure contents—must meet strict safety and quality standards. One critical step in this process is the internal inspection of these cylinders, where defects such as corrosion, pitting, weld irregularities, cracks, or contamination can compromise integrity and safety.

However, inspecting the inside of a narrow, high-pressure cylinder presents significant challenges. The internal diameter is often too small to accommodate standard machine vision cameras, and the internal surfaces can be hard to illuminate and capture effectively. Traditionally, this inspection has been performed using boroscopic cameras, with human operators visually checking the images on a monitor.

Intelgic takes this process several steps further—automating internal cylinder inspection using advanced image processing software, intelligent motion control systems, and AI-powered defect detection.

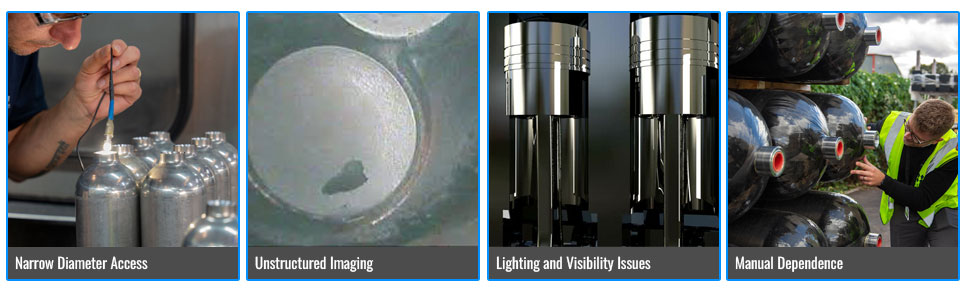

Challenges in Internal Cylinder Inspection

Narrow Diameter Access

Most cylinders have internal diameters that prevent the use of conventional area or line scan cameras. Access is limited, making both lighting and imaging difficult.

Unstructured Imaging

Boroscopic cameras are manually moved, producing frame-by-frame images in non-linear, sometimes inconsistent directions.

Lighting and Visibility Issues

Lighting inside a cylinder is highly constrained. The reflective or matte nature of internal surfaces can create glare, shadows, or dark regions.

Manual Dependence

Human inspectors rely on experience and concentration to detect tiny surface flaws while viewing video or image streams—a process that is time-consuming and error-prone.

Intelgic’s AI-Powered Inspection Solution

Intelgic transforms this traditionally manual task into a scalable, repeatable, and accurate automated inspection system with the following core components:

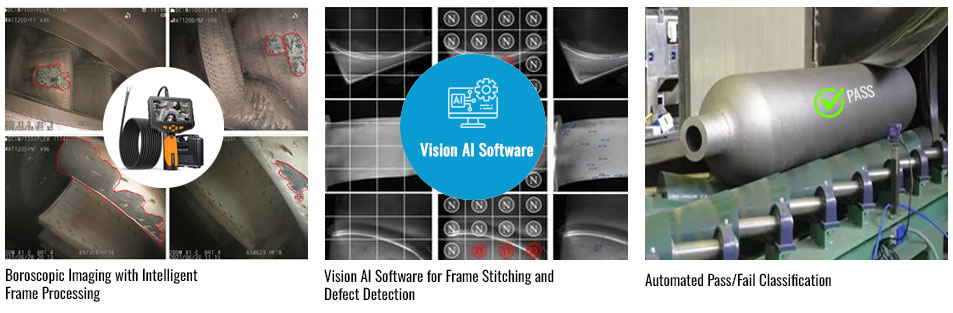

1. Boroscopic Imaging with Intelligent Frame Processing

- The system uses standard boroscopic cameras to capture internal images frame by frame.

- These cameras are compatible with Intelgic’s software and lighting modules, ensuring visibility in confined and curved spaces.

2. Vision AI Software for Frame Stitching and Defect Detection

- Intelgic’s Live Vision AI software accepts real-time or recorded frame sequences.

- Each frame is processed to:

- Correct orientation (to align camera rotation)

- Stitch sequential frames into a linear or cylindrical representation

- Detect defects such as:

- Corrosion patches

- Pits and pinholes

- Cracks and weld defects

- Contamination or deposits

- The software uses deep learning models trained on various defect types, materials, and surface textures.

3. Automated Pass/Fail Classification

- Based on customer-defined acceptance criteria (e.g., defect size, depth, density), each cylinder is classified as Pass or Fail.

- A comprehensive inspection report is generated with:

- Annotated defect locations

- Image evidence

- Timestamp and cylinder ID

- Operator/machine ID (for traceability)

Optional: Robotic Camera Movement System

Intelgic offers a motorized motion system to automate the movement of the boroscopic camera:

- Precision-controlled actuators move the camera linearly and rotationally inside the cylinder.

- Ensures complete coverage of the internal surface in a systematic spiral or raster path.

- Eliminates inconsistencies and human fatigue in manual scanning.

This motion system is customizable based on the cylinder’s length, diameter, and inspection specifications.

System Components Supplied by Intelgic

|

Component |

Description |

|

Boroscopic Camera |

Compact, high-resolution camera with integrated LED lighting |

|

Lighting System |

Custom-built miniature lighting for clear internal surface illumination |

|

Robotic Motion System |

Controlled movement for consistent internal scanning |

|

Live Vision AI Software |

Frame stitching, defect detection, reporting, and pass/fail classification |

|

Control Interface (HMI) |

User interface for live monitoring, configuration, and report download |

Benefits of Intelgic’s Automated Cylinder Inspection

- Minimized Human Error: AI ensures objective, consistent inspection across batches.

- High Throughput: Faster inspections with robotic movement and real-time processing.

- Traceable Records: Detailed defect logs and pass/fail history for compliance and audits.

- Defect Localization: Accurate coordinates of each defect, aiding repair or rejection decisions.

- Modular Integration: Can be integrated into existing inspection lines or retrofitted into current setups.

Use Cases

- Oxygen Cylinder Manufacturing Plants

- Hydrogen Storage Cylinder Reconditioning

- High-Pressure Cylinder Inspection Centers

- Aerospace/Defense Cylinder Compliance Checks

- Medical or Pharmaceutical Gas Cylinder Inspection

Inside-cylinder inspection is a demanding task, but with Intelgic’s innovative AI-driven solution, manufacturers and inspectors can now ensure complete quality control with speed, accuracy, and confidence. By combining boroscopic imaging with intelligent motion control and machine vision software, Intelgic delivers a turnkey system designed to meet the evolving demands of industrial safety and automation.

For more information, demo requests, or integration support, contact the Intelgic team.