Improving Warranty Management with AI-Powered Machine Vision

Published on: Jun 16, 2025

Written by: Content team, Intelgic

The Core of the Solution: Intelgic’s Machine Vision AI System

Intelgic’s inspection automation platform is designed to provide complete visibility and traceability throughout the manufacturing process. The system consists of the following key components:

- High-Resolution Cameras (IP or industrial machine vision cameras)

- Industrial Lenses and Optics (including telecentric and zoom lenses)

- Specialized Lighting (such as dome, coaxial, ring, or line-scan lighting)

- AI-Powered Software for real-time defect detection, data logging, and cloud-based reporting

This infrastructure forms the foundation for a robust inspection and tracking system, covering both product quality and assembly accuracy.

Automated Quality Inspection

Intelgic’s AI system is deployed on the inspection line to conduct real-time quality checks on every product. Here’s how it works:

- Products are imaged in detail using high-resolution cameras and calibrated lighting setups.

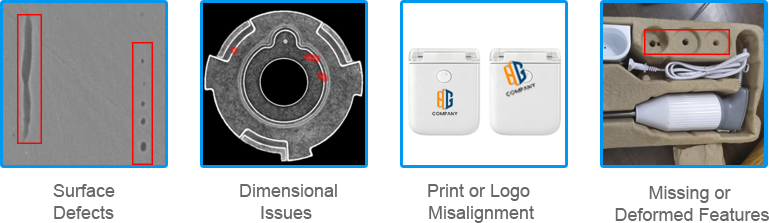

- The captured images are analyzed by Intelgic’s AI-powered defect detection software, which identifies anomalies such as:

- Surface defects (scratches, dents, cracks)

- Dimensional issues

- Print or logo misalignment

- Missing or deformed features

- Surface defects (scratches, dents, cracks)

- Every product inspected generates a comprehensive digital report detailing:

- Type and severity of defect (if any)

- Image snapshots of the defective regions

- Pixel-level analysis and coordinates of anomalies

- Type and severity of defect (if any)

- All data is stored securely on the cloud, timestamped and indexed by serial or batch number.

This approach allows manufacturers to implement 100% inspection coverage without relying on subjective human checks, significantly improving consistency and traceability.

Assembly Line Monitoring and Verification

In addition to quality inspection, Intelgic’s system monitors assembly line activities in real time to prevent and record assembly-related errors:

- Cameras monitor key assembly stages to ensure:

- Correct component placement

- Proper wire connections or fastening

- Presence of critical subassemblies

- Conformance to Standard Operating Procedures (SOPs)

- Correct component placement

- AI models are trained to recognize deviations, such as:

- Misplaced or missing parts

- Incorrect wiring or orientation

- Skipped steps or out-of-sequence assembly

- Misplaced or missing parts

- A batch-level assembly report is generated, allowing manufacturers to trace issues back to specific operators, shifts, or workstations.

This dual-inspection capability ensures that both product quality and assembly integrity are tracked, reported, and stored in an accessible digital format.

Warranty Claim Validation Through Cloud-Based Traceability

When a customer complaint or warranty request arises, manufacturers often face a dilemma: accept the claim without evidence, or risk reputational damage by disputing it without proof. Intelgic eliminates this ambiguity through data-backed validation:

- Operators can retrieve inspection and assembly reports from the cloud by scanning the product’s serial or batch number.

- This data includes:

- Image evidence of the product at various production stages

- Results of AI-based defect checks

- Assembly verification logs

- Image evidence of the product at various production stages

- With this level of documentation, manufacturers can:

- Validate or reject claims based on actual inspection records

- Identify systemic issues in the process that led to defects

- Improve accountability across suppliers, operators, and production units

- Validate or reject claims based on actual inspection records

This approach fosters a transparent and defensible warranty system while protecting manufacturers from fraudulent or inaccurate complaints.

Business Benefits of Intelgic’s Warranty Improvement System

Implementing Intelgic’s Machine Vision AI platform delivers measurable business outcomes:

- Reduced Cost of Warranty Claims: Catching defects before shipping reduces expensive recalls or replacements.

- Faster Root Cause Analysis: Trace back quality failures to specific batches, machines, or personnel.

- Improved Customer Satisfaction: Swift and accurate complaint validation demonstrates professionalism and builds trust.

- Regulatory Compliance: Maintain detailed inspection logs for audits, certifications, and safety regulations.

- Data-Driven Continuous Improvement: Use insights from inspection trends to optimize design, process, and training.

Reinventing Warranty Management with AI

Warranty management no longer needs to be reactive or reliant on customer narratives. With Intelgic’s Machine Vision AI solution, manufacturers can validate customer complaints with precision, streamline recall decisions, and optimize product quality from the ground up.

By embedding intelligent inspection systems at the heart of production and assembly lines, Intelgic empowers businesses to transition from cost-driven damage control to data-driven warranty excellence.