How Intelgic’s Assembly Line Monitoring Solution Is Reducing Assembly Errors and Increasing Product Quality

Published on: Sep 18, 2025

Written by: Content team, Intelgic

AI-Powered Visual Intelligence for Error-Free Manufacturing

In the ever-evolving landscape of automotive manufacturing, ensuring flawless assembly processes is crucial to delivering high-quality products and minimizing warranty claims. Assembly errors—whether caused by human oversight or machine malfunction—can lead to significant costs, production delays, safety risks, and compromised brand reputation.

Intelgic is at the forefront of solving this challenge with its AI-powered assembly line monitoring solution, designed specifically to detect and prevent errors in real time. By combining advanced machine vision systems, AI-based frame analysis, and seamless integration with PLCs and automation infrastructure, Intelgic is helping manufacturers significantly reduce assembly defects and improve overall product quality.

The Problem: Assembly Line Errors Are Costly and Common

In complex automotive environments, where hundreds of parts come together in highly synchronized assembly lines, even a single error can disrupt the entire production flow. Common assembly-related issues include:

- Incorrect part installation

- Missing components (bolts, clips, gaskets, etc.)

- Improper torque or alignment

- Foreign object intrusion

- Incomplete or skipped assembly steps

- Machine setup inconsistencies

These errors are often difficult to detect in real time—especially in manual or semi-automated operations. Traditional quality checks may miss these faults or identify them too late, resulting in expensive rework or defective units reaching customers.

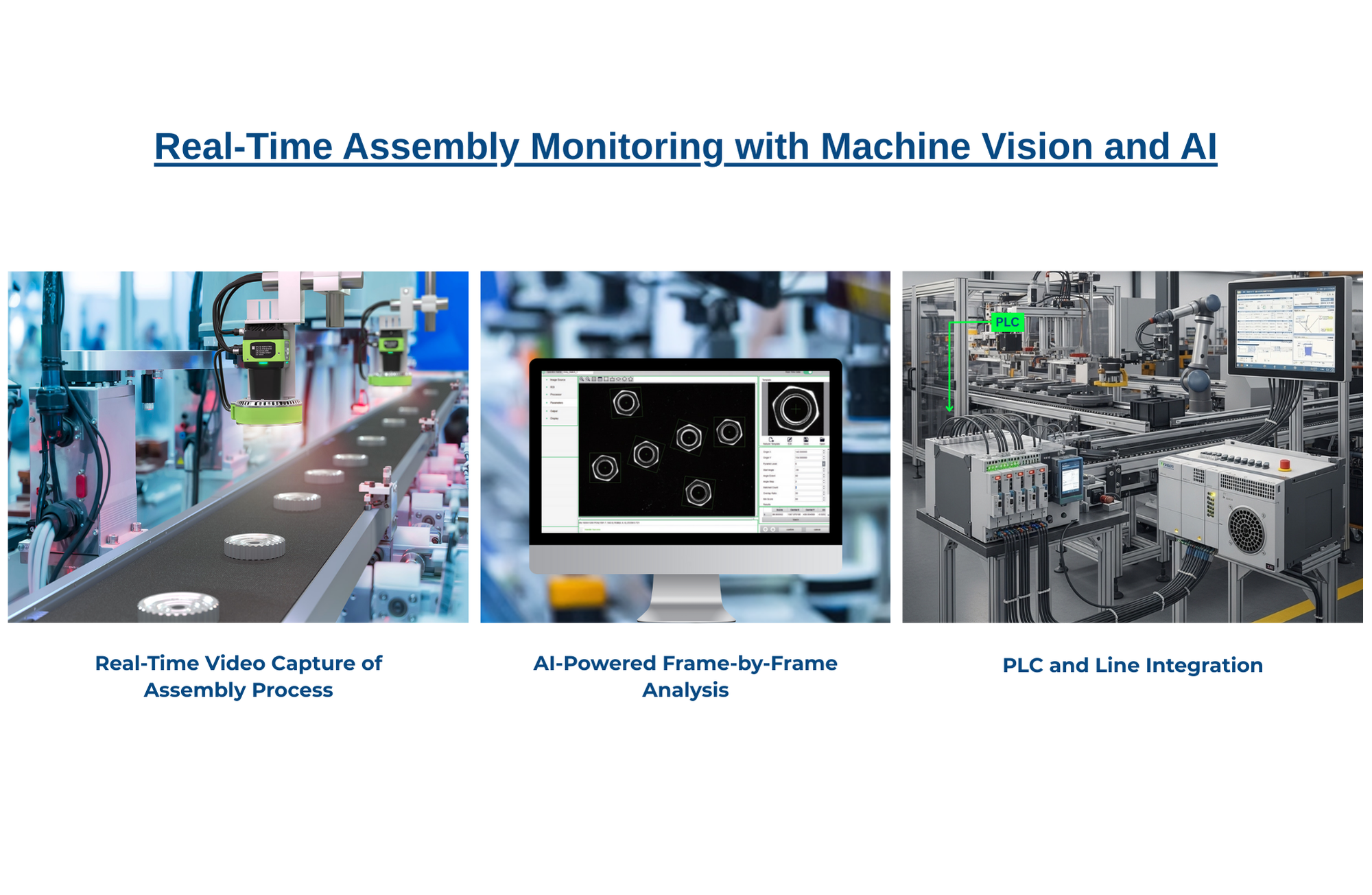

Intelgic’s Solution: Real-Time Assembly Monitoring with Machine Vision and AI

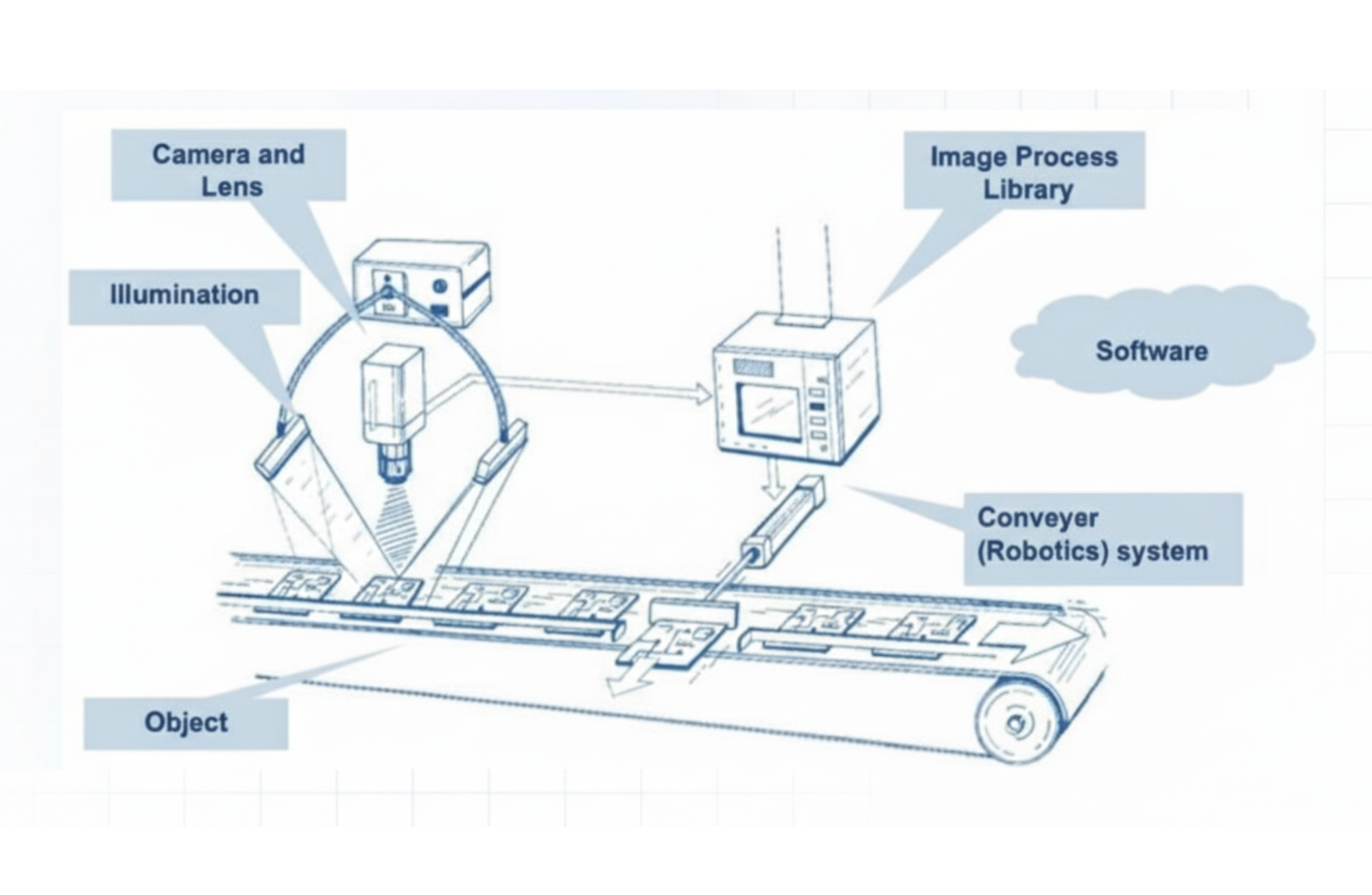

Intelgic has developed a turnkey machine vision AI solution that acts as an intelligent supervisor for your assembly line. The system works in three key stages:

1. Real-Time Video Capture of Assembly Process

High-resolution industrial cameras are strategically installed along the assembly line to capture continuous video or still images of each station. These can be:

- Manual assembly workstations

- Semi-automated stations

- Fully robotic cells

Cameras are positioned to capture key angles and areas—such as component placement zones, tool engagement points, fastening areas, etc.

2. AI-Powered Frame-by-Frame Analysis

Intelgic’s proprietary Live Vision AI software continuously analyzes video feeds frame by frame in real time. The AI engine is trained on correct vs incorrect assembly scenarios using a combination of:

- Deep learning models (e.g., CNNs for object detection/classification)

- Image processing and geometry-based techniques

- Temporal logic to understand sequence of operations

The system can detect:

- Wrong or reversed part placement

- Missing parts

- Improper tightening/fastening

- Sequence deviation

- Surface damage or contamination during assembly

When a deviation is detected, the system instantly raises an alert, providing operators and supervisors with actionable feedback—whether visual signals (lights), audible alarms, or digital notifications.

3. PLC and Line Integration

Intelgic’s solution is designed for seamless integration with your existing PLC or automation system. If a critical error is detected:

- The system can halt the assembly line

- Send error codes to the PLC for downstream action

- Trigger interlocks or engage robotic rework procedures

- Suggest corrective measures based on error patterns

This closed-loop feedback not only improves detection accuracy but also enables self-correction and optimization at the machine or line level.

Benefits Delivered

Intelgic’s assembly line monitoring system delivers measurable improvements in manufacturing performance:

Reduction in Assembly Errors

Real-time detection and alerting drastically reduce missed errors and rework.

Improved Product Quality

By catching assembly defects at the source, the system ensures higher output quality and fewer field failures.

Faster Root Cause Analysis

The AI engine logs all detected anomalies along with timestamped images and video. This data supports fast diagnosis and continuous improvement.

Enhanced Automation Reliability

Integration with PLCs and robotic systems creates a responsive, intelligent automation loop that adjusts to error patterns.

Lower Warranty and Recall Costs

Improved assembly accuracy leads to fewer customer complaints, warranty claims, and recalls.

Use Cases in Automotive Assembly

Intelgic’s solution is already deployed across several automotive sub-assembly lines, including:

- Headlamp Assembly

Detect missing screws, incorrect bulb fitting, reversed brackets.

- Engine Subsystems

Monitor sensor placement, gasket fitment, bolt torqueing.

- Body and Chassis Components

Verify panel alignment, clip positioning, and adhesive application.

Interior Modules

Ensure correct dashboard, HVAC, and wiring harness installation.

Intelligent Reporting and Traceability

Each inspection and detection event is logged in Intelgic’s cloud-connected dashboard. Manufacturers can:

- Track error trends by station/operator/time

- Generate quality reports and digital inspection certificates

- Integrate data with MES, ERP, or quality assurance systems

This complete traceability empowers smarter decision-making, continuous process refinement, and audit compliance.

Customization for Every Line

Intelgic understands that every assembly line is different. That’s why the solution is:

- Custom-built for your part, process, and layout

- Compatible with multiple camera setups, lighting geometries, and lens types

- Configurable to manual, semi-automated, or fully robotic assembly

Our engineering team collaborates with you to design, train, and deploy a solution that aligns with your production goals.

Conclusion: Building Toward Zero-Defect Assembly

Intelgic’s AI-driven assembly line monitoring solution is transforming the way manufacturers approach quality control. By proactively detecting errors during the assembly process—rather than relying on post-assembly inspections—it enables true zero-defect manufacturing.

In an industry where quality is non-negotiable, Intelgic ensures that every bolt, clip, and component is in its right place—every time.