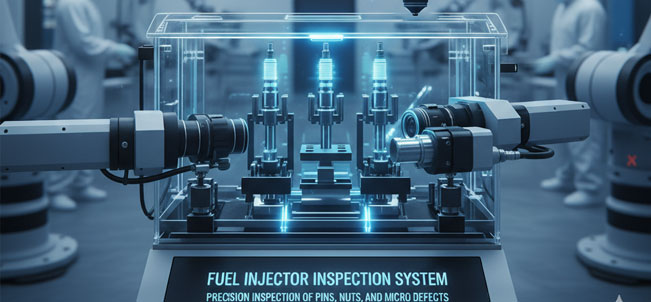

Fuel Injector Inspection System-Precision Inspection of Pins Nuts and Micro Defects

Published on: Sep 26, 2025

Written by: Content team, Intelgic

Fuel injectors are one of the most critical components in modern combustion engines. Their performance directly affects fuel efficiency, emission control, and engine life. Even a micron-level defect in the injector pin, nut, or sealing surface can lead to leakage, improper atomization, or complete injector failure. For manufacturers of automotive and industrial engines, ensuring flawless injectors is non-negotiable.

Intelgic’s Machine Vision AI–based Fuel Injector Inspection System is designed to meet these high demands by automating the inspection of pins, nuts, and injector assemblies for alignment defects, micro deformities, and surface anomalies.

Why Automated Fuel Injector Inspection Is Critical

Fuel injectors have highly precise geometry. A minor scratch, burr, or misalignment can cause:

- Fuel leakage leading to reduced performance and safety issues.

- Inconsistent spray patterns that affect combustion and increase emissions.

- Injector failure in the field, resulting in warranty claims and higher costs.

- Rejection by OEMs, as global standards demand zero-defect components.

Manual inspection under microscopes is slow, inconsistent, and operator-dependent. Automated inspection ensures 100% inline quality control, high repeatability, and detailed traceability for every part produced.

Key Inspection Areas

Intelgic’s system covers the full spectrum of fuel injector component inspection:

1. Pin Inspection

- Alignment Verification: Ensures the pin is precisely aligned within the injector body.

- Micro Defect Detection: Identifies scratches, dents, burrs, and cracks smaller than 10 microns.

- Deformity Detection: Checks for bending, uneven surface finishing, or dimensional mismatch.

2. Nut Inspection

- Thread Quality Check: Detects damaged, missing, or poorly formed threads.

- Surface Defect Analysis: Identifies scratches, corrosion, or contamination.

- Geometric Verification: Ensures nut concentricity and dimensional tolerance.

3. Injector Body and Assembly

- Gap Measurement between components.

- Seal Area Inspection to detect chips, cracks, or misalignment.

- Presence/Absence Verification of small subcomponents.

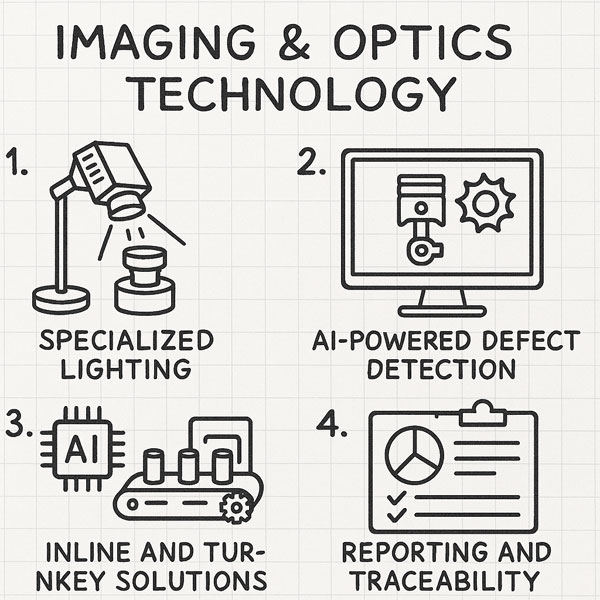

Imaging & Optics Technology

To achieve micron-level precision, Intelgic uses a combination of advanced imaging technologies:

High-Resolution Area Scan Cameras (20 MP–65 MP) for detailed inspection of tiny injector components.

Telecentric Lenses to capture distortion-free images of small parts.

Specialized Lighting:

Coaxial lighting for flat reflective surfaces.

Low-angle lighting to highlight scratches and micro burrs.

Dome lighting to minimize glare on polished surfaces.

AI-Powered Defect Detection

The captured images are analyzed using Intelgic’s Live Vision AI software, which combines:

Rule-based measurement algorithms for precise dimensional checks.

Deep learning models for anomaly and micro defect detection.

Classification modules to sort defects by type (scratch, burr, misalignment, deformation).

The software can detect defects as small as 5–10 microns — well beyond human visual capability.

Inline and Turnkey Solutions

Intelgic provides both inline inspection systems for high-speed production lines and standalone microscope-replacement stations for R&D or low-volume inspection.

Inline Inspection: Integrated with conveyor systems or robotic handling for 100% part screening.

Robotic Motion System: Multi-axis positioning for imaging pins, nuts, and complex geometries from multiple angles.

Cobot-Based Solutions: Collaborative robots load/unload injectors for flexible deployment.

Reporting and Traceability

Every inspected injector generates a digital quality report containing:

Defect location and type.

Measured values (gap, alignment, dimension).

Pass/Fail decision per acceptance criteria.

A Digital Quality Certificate (DQC) stored in the cloud for traceability and warranty validation.

Benefits to Manufacturers

- Zero-Defect Manufacturing with reliable micro defect detection.

- Increased Productivity by automating manual microscope inspection.

- Reduced Warranty Claims by catching early-stage defects.

- Scalability across multiple injector models and designs.

- Compliance with strict automotive quality standards (IATF 16949, ISO/TS 16949).

Fuel injector pins, nuts, and assembly parts require extreme precision inspection that is nearly impossible to achieve consistently with manual methods. Intelgic’s Fuel Injector Inspection System brings together industrial imaging, AI-driven defect detection, and robotic automation to ensure every injector meets the highest quality standards.

By adopting Intelgic’s turnkey inspection solutions, manufacturers can achieve faster production, lower rejection rates, and world-class product reliability.