Cylinder Inspection Automation with Automated Optical Inspection System

Published on: May 28, 2025

Written by: Content team, Intelgic

Cylinder Inspection Automation with Automated Optical Inspection System

From driving innovation in automotive engineering to ensuring reliability in aerospace and industrial applications, cylinders are critical components across a wide spectrum of industries. Their varied shapes, sizes, and surface finishes demand uncompromising quality and precision. However, in today’s high-speed manufacturing environments, manual inspection methods fall short of ensuring consistent quality at scale. Enter AI-powered Automated Optical Inspection (AOI) systems—revolutionizing defect detection with superior accuracy, speed, and scalability. By integrating intelligent algorithms with high-resolution imaging, AOI transforms cylinder inspection into a streamlined, data-driven, and future-ready quality assurance process.

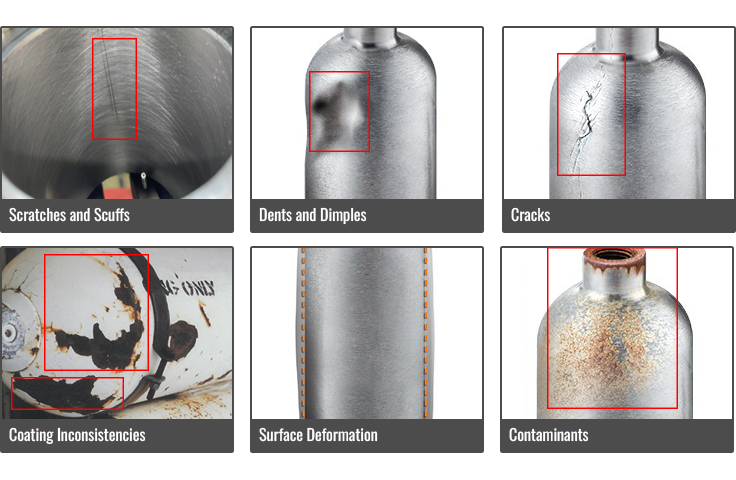

Common Defects in Cylinder Inspection

Cylinders are susceptible to a variety of surface and structural defects, many of which are difficult to detect through manual inspection. AI-powered AOI systems are designed to identify and classify these issues with remarkable precision. Some of the most common defects include:

- Scratches and Scuffs: Minor surface abrasions caused by handling, machining, or friction.

- Dents and Dimples: Small depressions or indentations resulting from impact or pressure.

- Cracks: Surface or subsurface fractures that may compromise structural integrity and performance.

- Corrosion and Discoloration: Oxidation or chemical damage leading to rust, stains, or uneven coloring.

- Coating Inconsistencies: Variations in paint, powder coating, or protective finishes—such as streaks, bubbles, or peeling.

- Contaminants: Presence of foreign particles like dust, oil, or metal shavings that affect quality and appearance.

- Surface Deformation: Warping or irregular shapes due to manufacturing defects or material fatigue.

Challenges in Cylinder Inspection

The cylinder inspection process poses unique challenges due to the diversity of product characteristics and manufacturing variables:

- Diverse Shapes and Sizes

Cylinders come in various diameters and lengths, requiring flexible systems that can adapt to different specifications.

- Rotational Nature

During inspection, cylinders often rotate. Inspection systems must synchronize image capture with this motion to ensure complete surface analysis.

- Reflective and Shiny Surfaces

Highly polished metal surfaces reflect light and cause glare, complicating defect detection without optimized lighting setups.

- Textured Surfaces

Some cylinders feature grooves, coatings, or patterns that make distinguishing between textures and actual defects a complex task.

- High-Speed Production

Manufacturers need inspection systems capable of real-time analysis without interrupting production flow.

Key Components of AOI for Cylinder Inspection Automation

High-Resolution Imaging Systems

Capturing detailed surface images is essential for accurate defect detection in cylinder inspection. High-resolution imaging systems enable AI-powered AOI to identify even the most subtle anomalies. Depending on the application, the following camera types are commonly used:

- Line-Scan Cameras

Ideal for rotating cylinders, these cameras capture continuous image strips as the surface moves, creating a seamless 360° view for complete inspection without blind spots.

- Area-Scan Cameras

Best suited for stationary or slow-moving cylinders, area-scan cameras capture the entire surface in a single frame, delivering detailed still images for precise analysis.

- Multi Camera Setups

In complex inspection scenarios, multiple cameras are arranged around the cylinder to provide comprehensive coverage from all angles. This setup captures hard-to-reach areas, such as edges, grooves, and recessed surfaces, ensuring no defect goes unnoticed.

2. Advanced Lighting Solutions

Effective lighting is vital for clear visibility and accurate defect detection on cylinder surfaces, especially those with reflective or textured finishes. Advanced lighting techniques address these challenges:

- Diffused Lighting: Provides soft, even illumination that reduces glare and highlights subtle defects like fine scratches or minor irregularities.

- Directional Lighting: Casts light at angles to emphasize grooves, dents, and texture variations through shadows and highlights.

- Multi-Angle Illumination: Uses multiple light sources to ensure thorough surface coverage, revealing hidden defects on complex or shiny surfaces.

- Texture-Differentiating Setups: Tailors lighting to differentiate between intentional surface patterns and actual defects, enhancing AI detection accuracy.

3. Synchronization with Rotational Motion

- Encoders: Track the rotation and ensure precise imaging synchronization.

- Real-Time Image Stitching: Combines images into a seamless 360° view for analysis.

4. Industrial-Grade System Design

- Protective Casings: Shield components from dust, vibrations, and heat.

- Integrated Cooling Systems: Ensure consistent performance in high-demand environments.

5. AI-Powered Defect Detection Software

At the core of advanced Automated Optical Inspection (AOI) systems lies powerful AI-driven software, designed to deliver precise and efficient defect detection:

- Advanced Anomaly Detection:

Utilizing sophisticated algorithms, the software analyzes cylinder surface images to identify irregularities such as scratches, cracks, dents, and other defects that could affect quality. This enables early detection of issues that traditional inspection methods might miss.

- Comprehensive Defect Categorization:

After detection, defects are systematically classified by type, size, severity, and precise location on the cylinder. This detailed categorization supports targeted quality control and effective decision-making on the production line.

- Instantaneous Defect Reporting:

The AI processes image data in real time, delivering immediate feedback during production. This rapid analysis helps quickly flag defective parts, reducing waste and preventing faulty products from progressing further.

- Continuous Learning and Improvement:

The system refines its detection capabilities over time by learning from new defect data and inspection results. This adaptive learning ensures the AOI system becomes increasingly accurate and dependable with ongoing use.

Step by Step Process of Cylinder Inspection Automation

- Cylinder Placement

The cylinder is carefully positioned on a rotating platform or conveyor to ensure complete surface exposure during inspection.

- Setup of Imaging System

Cameras and lighting equipment are precisely arranged to capture the entire surface with optimal clarity.

- Image Acquisition

As the cylinder rotates, high-resolution images are continuously captured to create a full 360-degree view.

- AI-Based Defect Detection

The images are analyzed in real time by AI algorithms that accurately identify and classify any surface defects.

- Defect Documentation

A detailed report is generated, recording the type, severity, and location of each detected defect.

- Sorting and Quality Control

Defective cylinders are either flagged for further inspection or automatically removed from the production line to uphold quality standards.

Industry Applications

- Automotive: Ensuring quality of pistons, engine cylinders, and hydraulic parts for reliable performance.

- Aerospace: Inspecting structural and hydraulic cylinders to meet strict safety standards.

- Manufacturing: Detecting defects in shafts, rollers, and pipes to maintain machinery efficiency.

- Energy: Monitoring pipelines, pressure vessels, and gas cylinders to prevent failures and enhance safety.

Future Trends of AOI in Cylinder Inspection

As industries continue to evolve, Automated Optical Inspection (AOI) systems are poised to become even more sophisticated and integral to cylinder quality control. Key future trends shaping this field include:

- Enhanced AI and Machine Learning: Future AOI systems will leverage deeper machine learning capabilities to improve defect detection accuracy and reduce false positives by continuously learning from diverse data sets. This will enable more nuanced recognition of complex defects and variations.

- 3D Imaging and Surface Mapping: Advanced 3D imaging technologies will provide more detailed surface profiles of cylinders, allowing for comprehensive defect analysis beyond traditional 2D inspections. This will help detect subtle surface irregularities and dimensional deviations with greater precision.

- Edge Computing and Real-Time Analytics: Integrating edge computing will enable faster processing of inspection data directly on-site, reducing latency and supporting real-time decision-making without reliance on cloud connectivity.

- Adaptive and Predictive Maintenance: AOI systems will increasingly integrate with predictive maintenance tools, using inspection data to forecast potential failures and schedule proactive interventions, thereby minimizing downtime and extending equipment life.

- Increased Automation and Robotics Integration: The combination of AOI with robotic handling and sorting systems will further streamline production lines, enabling fully automated inspection, sorting, and quality assurance processes.

- Augmented Reality (AR) for Operators: AR technology may be introduced to assist operators by overlaying defect information and guidance during inspections, enhancing human-machine collaboration and speeding up troubleshooting.

How Intelgic Leading the Cylinder Inspection Automation

Intelgic stands at the forefront of intelligent inspection solutions, engineered to address the most demanding industrial challenges. Our AI-powered Automated Optical Inspection (AOI) systems deliver unparalleled precision, scalability, and seamless integration, customized to accommodate your specific cylinder dimensions, materials, and inspection criteria.

Key Advantages of Intelgic Solutions:

- Custom-Engineered Systems: Precisely designed to meet your unique production requirements and cylinder specifications.

- Advanced Technology: Equipped with high-resolution imaging, sophisticated lighting setups, and real-time AI analytics to ensure superior defect detection.

- Durable and Reliable: Constructed to maintain consistent performance in harsh industrial environments, minimizing downtime.

- Seamless Scalability: Effortlessly integrates with existing production lines, enabling smooth and efficient workflow continuity.

Implementing Intelgic’s automated cylinder inspection represents more than a technological enhancement—it is a strategic investment toward smarter, safer, and more efficient manufacturing operations. Guarantee the highest quality standards for every cylinder while optimizing your production efficiency.

Contact Intelgic today to discover how our cutting-edge AOI solutions can elevate your quality control processes and drive operational excellence.