Control Panel Assembly for Escalators Lifts and Elevators: Precision Safety and Automation

Published on: Sep 16, 2025

Written by: Content team, Intelgic

Building the Brain of Vertical Transportation Systems

In the realm of vertical transportation—whether it’s a high-rise elevator, a shopping mall escalator, or a residential lift—control panels serve as the central nervous system of operation. These panels house the essential components that govern movement, direction, speed, safety, and communication within these systems.

Control panel assembly for elevators, lifts, and escalators is a complex and precision-driven process. It involves not only electrical and mechanical integration but also a strong emphasis on safety, compliance, and quality control. As urban infrastructure expands and automation becomes the norm, the need for error-free assembly and inspection of control panels has become more critical than ever.

What Is a Control Panel in Elevators, Lifts, and Escalators?

A control panel is an enclosed unit that contains all the electrical and electronic components required to operate, monitor, and secure the movement of an elevator, lift, or escalator. These panels may be:

- Main control panels located in the control room or machine room

- Car operating panels (COPs) inside elevator cabs

- Landing operating panels (LOPs) at each floor level

- Escalator motor control panels housed near the drive mechanism

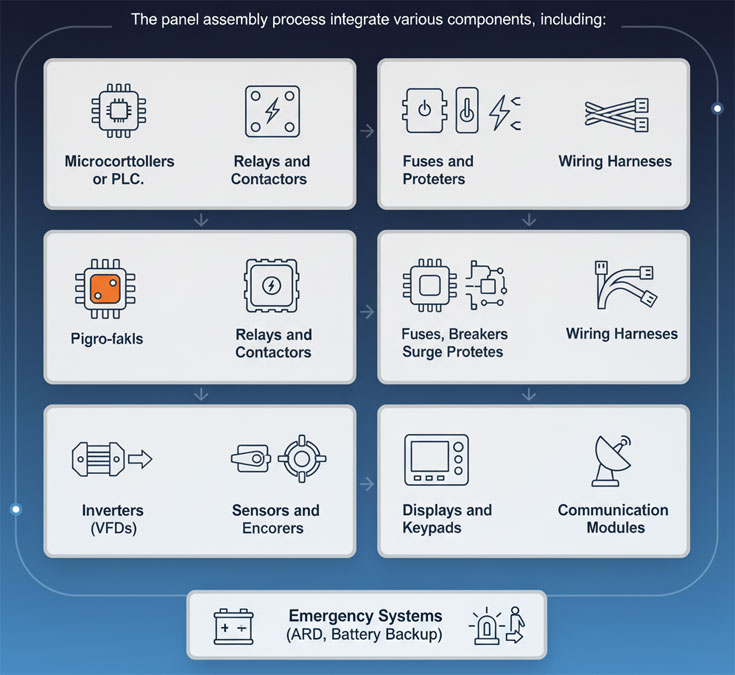

Key Components in Control Panel Assembly

The panel assembly process integrates various components, including:

- Microcontrollers or PLCs: The logic brain that executes commands

- Relays and Contactors: For switching high-voltage circuits

- Fuses, Breakers, and Surge Protectors: For safety and protection

- Wiring Harnesses: Interconnecting power and signal lines

- Inverters (VFDs): To control motor speed and direction

- Sensors and Encoders: To detect floor position, speed, and safety triggers

- Displays and Keypads: For human interface in the cab or floor panels

- Communication Modules: For remote monitoring, alarms, and IoT integration

Emergency Systems: Auto rescue devices (ARD), battery backups, alarms

Assembly Process: Precision Matters

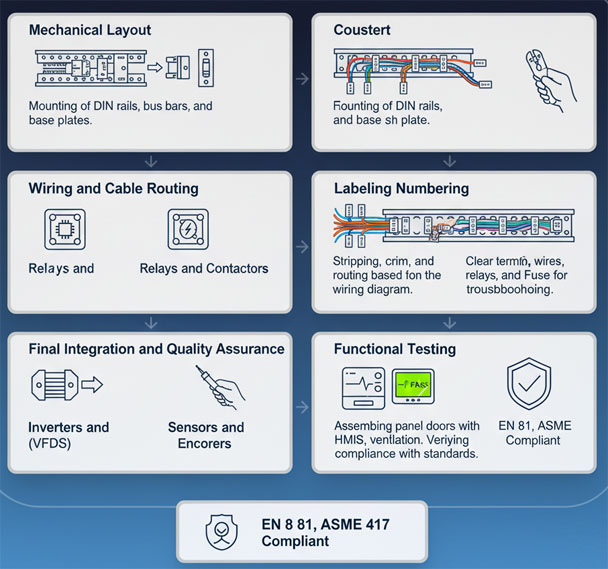

Control panel assembly involves the following steps:

- Mechanical Layout

- Mounting of DIN rails, bus bars, and base plates

- Placement of circuit breakers, contactors, and modules

- Mounting of DIN rails, bus bars, and base plates

- Wiring and Cable Routing

- Stripping, crimping, and routing wires based on the wiring diagram

- Organizing harnesses using ducts and clamps

- Stripping, crimping, and routing wires based on the wiring diagram

- Labeling and Numbering

- Clear marking of terminals, wires, relays, and fuses for easy troubleshooting

- Clear marking of terminals, wires, relays, and fuses for easy troubleshooting

- Functional Testing

- Power-on checks, short circuit testing, logic verification, simulation of safety interlocks

- Power-on checks, short circuit testing, logic verification, simulation of safety interlocks

- Final Integration and Quality Assurance

- Assembling panel doors with HMIs, ventilation, and lock systems

- Verifying compliance with standards like EN 81, ASME A17, or BIS

- Assembling panel doors with HMIs, ventilation, and lock systems

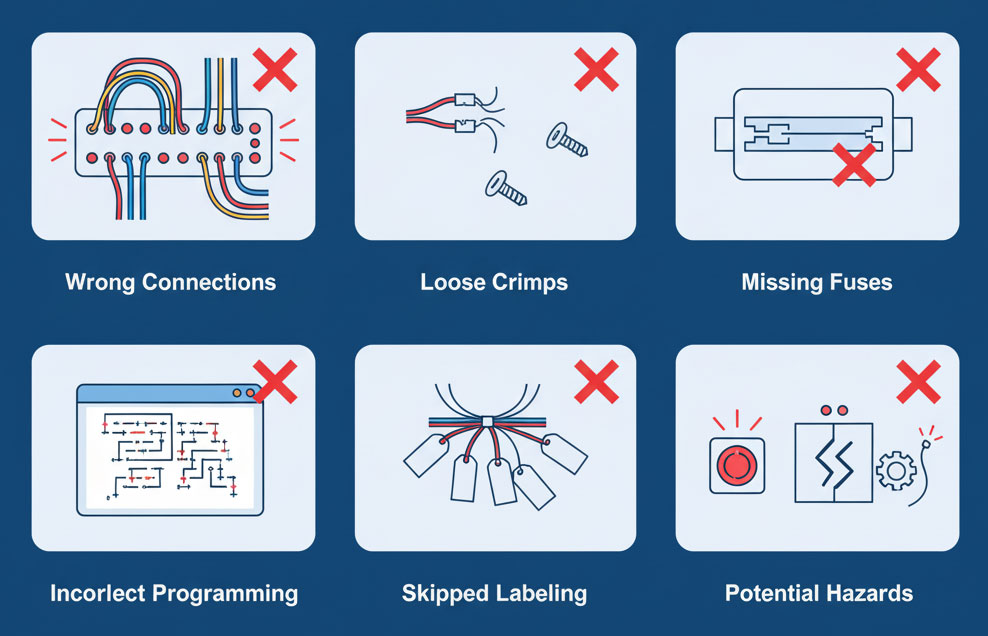

Challenges in Manual Assembly

Despite being a structured process, manual assembly can introduce errors such as:

- Wrong wire connections or swapped terminals

- Loose crimps or improperly tightened screws

- Missing fuses or wrongly rated protection devices

- Incorrect PLC programming or ladder logic

- Skipped labeling or documentation errors

These defects, if not caught early, can cause safety failures, escalator malfunctions, elevator shutdowns, or even hazards during emergency operations.

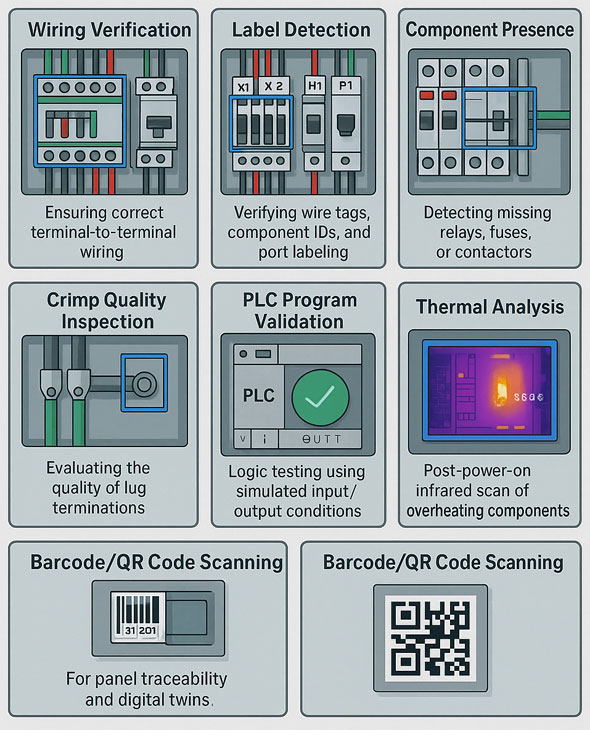

Automated Inspection for Control Panel Assembly

To address the quality challenges in control panel assembly, companies like Intelgic are bringing AI-powered vision systems and smart inspection technologies to the forefront.

Key AI-enabled Inspection Capabilities:

- Wiring Verification: Ensuring correct terminal-to-terminal wiring

- Label Detection: Verifying wire tags, component IDs, and port labeling

- Component Presence: Detecting missing relays, fuses, or contactors

- Crimp Quality Inspection: Evaluating the quality of lug terminations

- PLC Program Validation: Logic testing using simulated input/output conditions

- Thermal Analysis: Post-power-on infrared scan for overheating components

- Barcode/QR Code Scanning: For panel traceability and digital twins

This level of intelligent automation significantly reduces the likelihood of post-installation failures and improves safety compliance.

Applications Across Industry

Control panels are critical in a wide range of vertical transport systems:

- Commercial Elevators in Office Buildings and Malls

- High-Speed Lifts in Skyscrapers and Hotels

- Home Elevators and Dumbwaiters in Residences

- Hospital Elevators with Emergency Override Functions

- Escalators in Airports, Metros, and Shopping Centers

Each application may require specific features like group control, voice announcements, card-based access, or fire-mode operations—all of which must be supported and verified in the panel.

Compliance and Safety Standards

Panel assemblies must comply with national and international safety and electrical standards such as:

- EN 81, EN 115 – For lift and escalator safety

- ASME A17.1 / CSA B44 – Elevator and Escalator Code (North America)

- IEC 60204-1 – Safety of machinery electrical equipment

- NFPA 70 (NEC) – Electrical wiring safety standards

- ISO 13849 / 12100 – Risk assessment for machinery

Compliant control panels ensure not only the safety of passengers but also the reliability and uptime of critical infrastructure.

Future Trends

With the rise of smart cities and connected infrastructure, control panels are evolving with:

- IoT-enabled diagnostics and monitoring

- Remote firmware updates

- Predictive maintenance alerts

- Touchscreen HMIs with multilingual support

- AI-based load prediction and traffic management

As a result, assembly and inspection processes must evolve to handle greater complexity and digital integration.

Control panel assembly is not just a back-end process—it’s the foundation of safe and reliable vertical mobility. Whether it’s moving thousands of people through a metro station or ensuring seamless elevator access in a high-rise, the quality of control panel assembly makes all the difference.

With the integration of automated inspection, AI-based validation, and industry-standard compliance, manufacturers and system integrators can ensure every panel operates flawlessly from day one.

Looking to automate control panel inspection?

Intelgic offers custom machine vision and AI solutions for quality assurance in control panel manufacturing. Visit www.intelgic.com to learn more or schedule a free consultation.