Bore Inspection in Bearings and Metal Parts Using AI and Machine Vision

Published on: Jul 21, 2025

Written by: Content team, Intelgic

Introduction

Bores are critical internal features in many metal components—especially in precision automobile parts such as bearings, housings, bushings, sleeves, engine blocks, gears, and structural connectors. Even the smallest imperfection in a bore—such as a burr, surface scratch, concentricity error, out-of-roundness, or dimensional deviation—can lead to severe wear, reduced performance, product failure, or safety hazards.

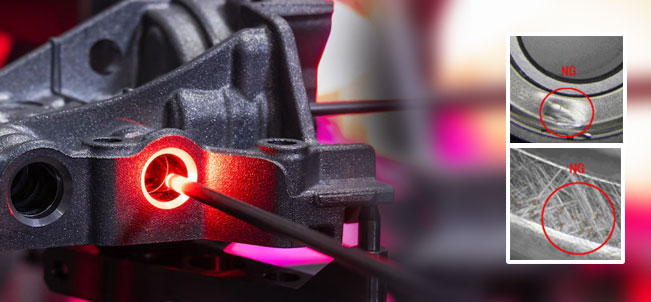

Traditional bore inspection using manual gauges or contact probes is not only time-consuming and error-prone, but often impractical for high-speed production lines. Intelgic solves this challenge with an AI-powered, non-contact bore inspection system that uses industrial cameras, advanced lighting, and precision optics to ensure complete quality verification—inside and around the bore.

Why Bore Inspection Matters

Why Bore Inspection Matters

-

Bearings: Imperfections in inner or outer bores can lead to misalignment, noise, and premature failure.

-

Engine Blocks and Cylinders: Bore diameter, taper, and surface roughness directly impact fuel efficiency and compression.

-

Gear Housings and Cases: Defects in mounting bores can affect alignment and cause mechanical imbalance.

-

Automotive/Industrial Components: Out-of-spec bores may lead to rejection during assembly, warranty issues, or recalls.

Intelgic provides a turnkey bore inspection system: Boroscopic Camera with Integrated Lighting for Bore Inspection

To inspect deep or narrow bores, Intelgic uses a 5 mm diameter boroscopic camera that is specially engineered for internal cavity imaging. This compact camera comes with a built-in high-intensity light source, allowing for clear, shadow-free visualization inside small or deep bores where conventional lighting techniques fail.

The integrated lighting ensures uniform illumination along the bore’s inner walls, making it possible to detect micro-defects such as:

-

Fine scratches and cracks

-

Burrs and debris

-

Coating inconsistencies

-

Heat marks or discoloration

-

Taper or dimensional anomalies

This all-in-one camera and lighting solution eliminates the need for external lighting setups and simplifies mechanical integration, especially for automated or inline inspection stations. The compact size and precision optics enable access to confined and curved spaces within a wide range of metal components.

The system performs both surface defect detection and dimensional analysis inside the bore, even in challenging conditions such as dark metal finishes, reflective surfaces, or curved inner walls.

Key Inspection Capabilities

Inner Surface Defect Detection

-

Scratches, dents, cracks, and contamination

-

Inner burrs or edge break issues

-

Heat marks, oxidation, or discoloration

-

Coating or finish anomalies

Dimensional Measurement

-

Bore inner diameter (ID) and roundness or circularity

-

Concentricity with respect to outer edges

-

Ovality, taper, and bore depth

-

Chamfer size and inner groove dimensions

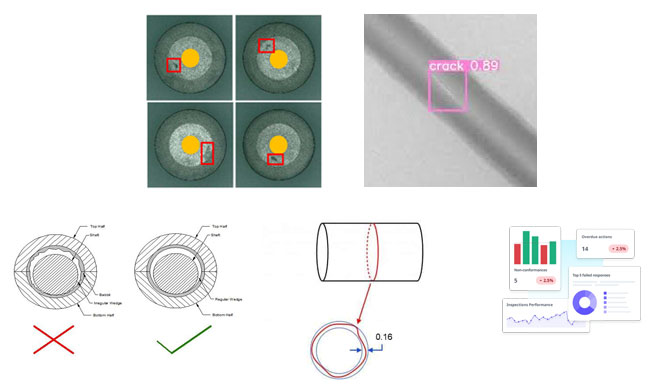

Intelgic’s software analyzes every image at the pixel level and reports defect regions with precise coordinates and severity, eliminating human subjectivity.

AI-Powered Image Processing and Automation

Intelgic’s Live Vision AI Software plays a central role by:

-

Capturing multiple images across varying focus depths (Z-axis scanning)

-

Applying advanced segmentation, pattern recognition, and defect classification

-

Auto-calibrating measurements to reference geometry

-

Detecting trends and deviation patterns for process control

-

Integrating with PLCs, MES, and cloud dashboards for traceability

The AI software adapts to variations in product appearance, tolerates some in-process variation, and constantly improves its decision-making through training data.

System Configuration and Integration

Intelgic offers both standalone desktop systems and inline inspection modules, with options such as:

-

Robotic arm-based inspection for complex shapes

-

Rotary motion platforms to rotate the part during inspection

-

Adjustable Z-axis for multi-depth scanning

-

API integration with MES/ERP systems for production tracking

-

Real-time alerts and visualization dashboards

Output and Reporting

Each inspection produces:

-

Image snapshots of defects with marked regions

-

Dimensional values with pass/fail flags

-

Summary of all defects with pixel counts and severity

-

Bore geometry profiling (circularity, taper, etc.)

-

Time-stamped digital inspection reports

These reports can be saved locally, uploaded to the cloud, or pushed to centralized quality control systems.

Applications

-

Ball and roller bearing inner ring bore inspection

-

Cylinder bore analysis in automotive and aerospace components

-

Motor housing bore surface defect detection

-

Hydraulic and pneumatic part inspection

-

Gear and sprocket bore quality verification

Benefits of Intelgic’s Bore Inspection System

-

Sub-Micron Defect Detection

-

Non-Contact, High-Speed Inspection

-

Real-Time Analytics & Reporting

-

Integration with Assembly Line Automation

-

Reduces Rework, Scrap, and Warranty Claims

-

AI Continuously Learns from New Defects

Bore inspection is no longer limited by manual tools or subjective judgment. With Intelgic’s AI-powered vision inspection system, manufacturers can now achieve 100% inline inspection of internal bores, ensuring both dimensional accuracy and surface quality at scale. Whether for bearings, engine blocks, or precision machined parts, Intelgic delivers consistent, reliable, and intelligent inspection automation—designed for Industry 4.0.