Automated Inspection of Complex Geometry Automotive Parts Made with Mixed Materials

Published on: Aug 14, 2025

Written by: Content team, Intelgic

Introduction

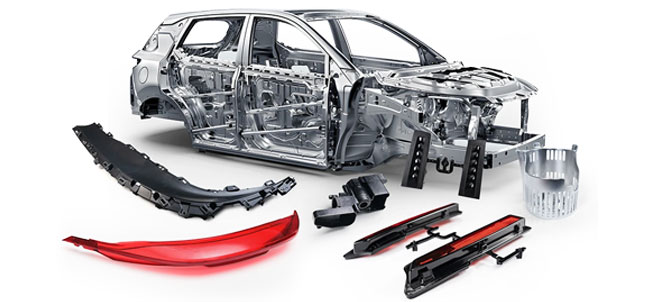

Automobile parts today are becoming more aerodynamic, lightweight, and functionally integrated, thanks to advanced design engineering and multi-material manufacturing. A single automotive component may combine metal, plastic, glass, and rubber, and feature shiny, transparent, matte, or textured surfaces — all in one part.

These mixed-material, complex geometry parts are extremely challenging to inspect using manual methods or standard vision systems. Intelgic offers a smart AI-powered machine vision solution tailored to inspect such sophisticated components with high accuracy, reliability, and speed.

Common Examples of Complex Multi-Material Automotive Parts

- Headlamps and Tail Lamps – Transparent polycarbonate, reflectors, metal clips, seals

- Door Trims and Inner Panels – Fabric, plastic, rubber, and metal supports

- Grilles and Fascia – Glossy painted plastic with metallic inserts

- Bumpers with Sensors – Painted surfaces, sensors, metallic brackets

- Engine Covers – Heat-resistant plastic + embedded metal components

- Instrument Clusters – Transparent display screen, printed plastics, metal frames

Inspection Challenges

Material Variation

Each material type responds differently to lighting:

- Plastic surfaces may reflect unevenly or appear semi-transparent

- Metallic areas cause glare and hotspots

- Rubber or matte areas absorb light and reduce contrast

Shiny and Transparent Zones

Reflective zones (e.g., chrome inserts, gloss finishes) and transparent parts (e.g., lenses) often confuse conventional vision systems, leading to false negatives or missed defects.

Complex Shapes and Hidden Areas

Curves, recesses, and sharp angles make uniform imaging difficult. Some areas may be hidden unless viewed from specific angles or using robotic motion.

Multilayer Assemblies

Multiple layers (e.g., lens + reflector + sealant) create depth and shadow artifacts. Inspection must detect both surface and sub-surface defects.

Intelgic’s Smart Inspection Solution

Intelgic builds custom AOI (Automated Optical Inspection) systems using:

Advanced Imaging Hardware

- High-resolution area scan or line scan cameras

- 3D profilers for surface topography

- Telecentric lenses to avoid distortion in depth

- Robotic motion systems (X, Y, Z) to view difficult zones

Adaptive Lighting Techniques

To overcome varied material reflectivity:

- Dome lights – Ideal for shiny and curved surfaces

- Dark field illumination – Highlights surface scratches and textural flaws

- Coaxial lights – Used for smooth reflective surfaces like glass or polished metal

- Ring and bar lights – For flat surfaces with localized lighting

- Backlights – For silhouette inspection of transparent components

- Polarizers – To reduce glare and enhance contrast across materials

Live Vision AI Software

Intelgic’s proprietary AI software performs:

- Defect detection – scratches, bubbles, cracks, weld issues, contamination

- Component verification – Ensure all parts are present and aligned

- Surface finish inspection – Identify inconsistencies in gloss, texture, or coating

- Text/logo reading – OCR for printed numbers, symbols on plastics or metal

- Pass/Fail logic based on part-specific criteria

AI learning – Model can be trained with new parts and updated defect patterns

System Features

|

Feature |

Description |

|

Multi-Angle Inspection |

Robotic camera movement ensures full surface coverage |

|

Material-Aware AI |

Adjusts detection logic based on material type |

|

High-Speed Processing |

Inline inspection at production speeds |

|

Comprehensive Reports |

Defect classification, image storage, DQC |

|

Cloud or On-Prem Deployment |

Flexible based on your infrastructure |

|

API Integration |

Connect with MES, ERP, SCADA systems |

Sample Inspection Use Cases

Headlamp Assembly Inspection

- Detect cracks in transparent lens

- Verify metallic clip presence and position

- Check reflector uniformity

- Inspect sealant application and welds

Painted Plastic + Metal Trim Inspection

- Surface finish inspection on plastic

- Detection of coating defects on metal inserts

- OCR verification of part number

Dashboard and Panel Inspection

- Ensure all components (screens, buttons, frames) are installed properly

- Check bonding, fitment, and gap alignment

Business Outcomes

- Reduced Customer Returns and Warranty Claims

- Improved Aesthetic and Functional Quality

- Faster Root Cause Analysis and Quality Feedback Loops

- Standardized, Scalable Quality Control

- Full Traceability through Digital Quality Certificates (DQC)

Digital Quality Reporting & Integration

- Defect heatmaps with visual annotations

- Size & location of defects in pixel or mm

- PDF/CSV reports with pass/fail history

- Integration with plant-level systems (MES, PLC, ERP)

- Cloud-based dashboards for real-time insights and analytics

Conclusion

In a world where form, function, and finish are equally important, inspecting complex automotive components made of multiple materials is no longer a luxury—it’s a necessity. Intelgic provides turnkey inspection solutions that adapt to the diverse material, geometric, and surface properties of modern automotive parts.

Let Intelgic help you scale precision, reduce errors, and drive quality excellence across your automotive production lines.