Automotive Shiny & Complex Metal Part Inspection using AI-Based Inspection system Intelgic

Published on: Aug 14, 2025

Written by: Content team, Intelgic

Introduction

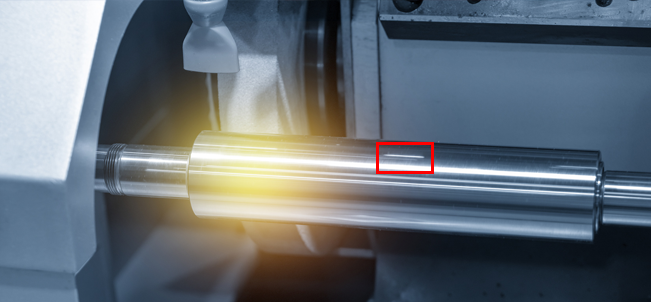

The automotive industry demands extreme precision and reliability, especially when it comes to metal parts used in critical assemblies. These components are often shiny, reflective, and geometrically complex, making them difficult to inspect using traditional visual methods or basic AOI systems. Defects such as scratches, dents, cracks, corrosion, coating issues, contamination, and surface irregularities must be detected with high precision—especially after processes like stamping, welding, machining, or painting.

Intelgic’s AI-powered Machine Vision System is designed specifically to handle the challenges of inspecting shiny and complex-shaped automotive components. Our system ensures zero-defect tolerance, improves first-pass yield, and enables traceability for every inspected part.

Why Inspection of Shiny and Complex Parts Is Challenging

Highly Reflective Surfaces

- Metal parts like engine brackets, structural reinforcements, fuel rails, control arms, etc., often have chrome-plated, painted, or polished surfaces.

- These surfaces reflect light unevenly, creating hot spots and glare, which can hide defects from conventional vision systems.

Irregular and Complex Geometries

- Parts may have holes, curves, weld beads, folds, corners, and deep recesses.

- These make uniform lighting and imaging extremely difficult, especially when capturing all surfaces.

Subtle Defects

- Minor defects like micro-cracks, pinholes, or pitting can be visually imperceptible.

- These defects can lead to performance failure if not detected early.

Variability in Size and Design

- A single inspection system must adapt to different part shapes, sizes, and surface finishes.

Manual inspection introduces human variability and increases inspection cycle time.

Intelgic’s End-to-End Inspection Solution

Advanced Imaging Hardware

- High-resolution machine vision cameras (area scan, line scan, or 3D cameras based on application)

- Telecentric lenses for distortion-free imaging

- Multi-axis robotic rails or gantry systems for full-surface coverage

- Industrial-grade lighting solutions tailored for reflective and irregular parts

Smart Lighting Techniques

Intelgic uses a combination of specialized lighting sources:

- Dome Lights – For uniform, shadowless lighting on curved or shiny surfaces

- Coaxial Lights – To highlight surface-level scratches and dents

- Dark Field Lights – Ideal for detecting edges and surface defects

- Structured Lighting/3D Profiling – For measuring weld beads, grooves, or embossed features

- Polarizers – To eliminate glare and reflections during inspection

Motion-Controlled Inspection

For large or complex parts:

- Robotic rails or articulated arms move cameras and lights along the X, Y, Z axis.

- Ensures every visible and hidden surface is captured from the correct angle.

Controlled via PLC and integrated with Intelgic’s Live Vision AI software.

Live Vision AI – Intelgic’s Inspection Software

Intelgic’s proprietary AI-powered vision software provides the intelligence behind defect detection. Features include:

- Defect classification: scratches, dents, pinholes, blisters, weld issues, contamination

- Real-time detection with image annotation

- Auto-marking of defect locations with coordinates

- Pixel/size-based defect measurement

- Pass/Fail logic based on customizable criteria

- Self-learning capabilities – Train AI with new parts and defect types

Traceability reports for every inspected part

Example Applications

After-Paint Inspection

- Detect scratches, specks, and uneven coatings on freshly painted metal parts

Forged or Stamped Part Inspection

- Inspect structural parts for cracks, splits, or die marks

Welded Assembly Inspection

- Validate bead continuity, surface cracks, or thermal deformities

Polished/Chrome-Plated Parts

- Identify micro-defects that could compromise aesthetics or function

Integration with Manufacturing Line

- Can be deployed inline or near-line based on production setup

- Interfaces with PLC, MES, and ERP systems via APIs

- Offers on-prem or cloud-based dashboards for:

- Real-time defect alerts

- Statistical process control

- Batch-wise analysis

- Real-time defect alerts

Digital Quality Certificates (DQC)

Business Outcomes

Reduced Warranty Claims

Increased First-Pass Yield

Lower Manual Inspection Costs

Faster Root Cause Analysis

Standardized and Scalable Inspection Process

Audit-Ready Documentation for OEM Compliance

Key Features at a Glance

|

Feature |

Description |

|

Imaging Hardware |

High-res cameras, robotic rails, smart lighting |

|

AI Software |

Defect detection, classification, pass/fail logic |

|

Flexible Deployment |

Inline, near-line, or offline stations |

|

Report & Analytics |

PDF/CSV/Cloud reports, DQC, real-time dashboards |

|

ERP/MES Integration |

API-based integration with factory systems |

Conclusion

Inspection of shiny and geometrically complex automotive parts is no longer a manual bottleneck. With Intelgic’s Vision AI Inspection System, manufacturers can achieve consistent quality, traceability, and cost savings—without compromising on speed or accuracy.

Ready to inspect the most difficult surfaces with ease?

📩 Contact us today for a demo or consultation.