Automated Inspection of Reflective Automotive Parts: Black Plastic Components in Chakpachuria

Published on: Sep 12, 2025

Written by: Admin

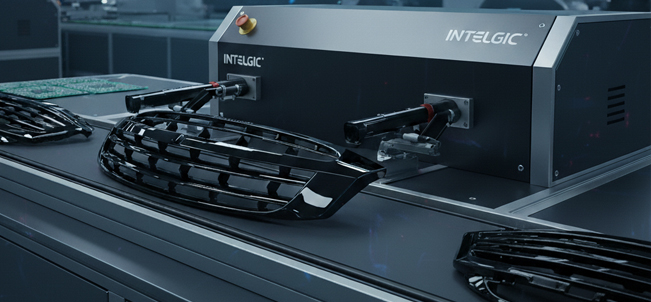

Shiny Black, Silver Automotive Components Inspection: Headlamp, Front-rear Mirror, Body parts

Modern automobiles are full of glossy, reflective surfaces—black plastic trims, dashboards, bezels, handles, and decorative elements. These parts are chosen for their aesthetic appeal but present unique inspection challenges. Even minor scratches, dents, contamination, or coating defects can be easily visible to customers, leading to warranty claims and reputational risks.

Traditional manual inspection often fails to detect subtle imperfections consistently, especially when reflections and lighting conditions change. Automated Optical Inspection (AOI) powered by machine vision and AI is now the industry’s solution to achieve zero-defect manufacturing for such parts.

At Intelgic, we design custom inspection systems specifically for reflective parts, ensuring even the smallest defect on a glossy black surface is detected reliably.

Challenges of Inspecting Reflective Black Plastic

Reflective materials pose specific difficulties:

- High Gloss & Mirror Effect – Black plastic often acts like a mirror, reflecting the environment, cameras, and lights. This causes false positives if lighting geometry is not carefully designed.

- Low Contrast Defects – Scratches, pinholes, or surface waviness may have extremely low contrast against the shiny background.

- Curved & Complex Shapes – Automotive trims and panels are rarely flat. Complex geometries distort reflections, making uniform inspection difficult.

- Lighting Sensitivity – A tiny change in light angle can make a defect either highly visible or completely invisible.

Micron-Level Sensitivity – Customers notice even micro-scratches (<50 µm), so inspection systems must detect extremely fine defects

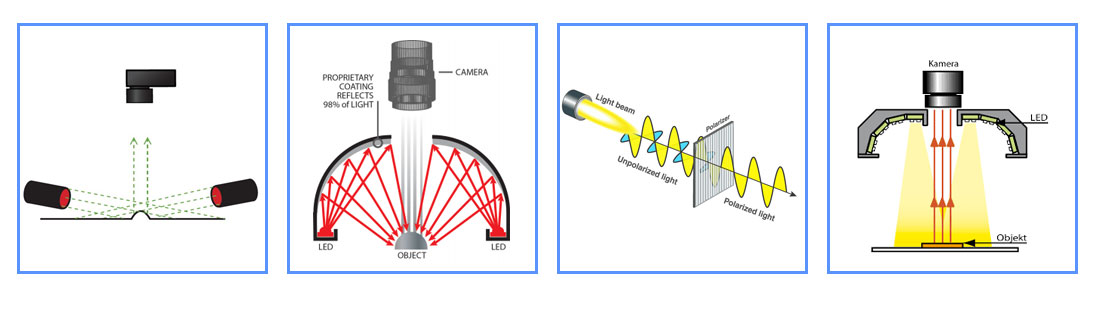

Lighting Geometry for Reflective Surface Inspection

The key to reliable inspection of black plastic is lighting design:

- Low-Angle Darkfield Lighting – Highlights scratches and dust particles by making them scatter light while the glossy background remains dark.

- Diffuse Dome Illumination – Eliminates sharp reflections and ensures uniform light distribution on curved glossy parts.

- Polarized Lighting – Suppresses specular reflections, increasing contrast for defects.

- Multi-Angle Lighting – Switching lights on/off at different angles ensures that all types of defects (scratches, dents, contaminations) become visible.

Intelgic integrates dynamic lighting systems controlled by software, allowing inspection recipes to adapt to different part shapes and surfaces.

AI vs. Traditional Image Processing

Traditional Approach

- Uses thresholding, edge detection, or template matching.

- Works for simple, consistent defects but struggles with reflective backgrounds.

- Requires precise fixturing and controlled environments.

AI-Based Approach (Deep Learning Anomaly Detection)

- Learns normal glossy surface patterns and flags anomalies (scratches, bubbles, inclusions).

- Tolerates lighting and positioning variations better.

- Detects unexpected defect types (e.g., contamination or coating variation) without rewriting inspection rules.

- Reduces false positives compared to rule-based vision.

Intelgic’s Reflective Part Inspection System

Our turnkey AOI system includes:

- High-Resolution Cameras – Area scan or line scan cameras, depending on part size and shape.

- Specialized Optics – Telecentric lenses for distortion-free imaging of flat regions, wide-angle for curved parts.

- Dynamic Lighting Modules – Dome lights, polarized ring lights, and low-angle lights controlled programmatically.

- Robotic Motion System – For 3D or curved parts, robotic stages rotate or move the part/camera for 360° coverage.

- Live Vision AI Software – Intelgic’s proprietary AI-driven platform detects, classifies, and measures defects.

- Detects scratches, dents, pinholes, contamination, waviness.

- Calculates defect size in microns/pixels.

- Provides Pass/Fail decision based on set acceptance criteria.

- Detects scratches, dents, pinholes, contamination, waviness.

Reporting & DQC (Digital Quality Certificate) – Each part gets a digital inspection record, enabling traceability, warranty validation, and supplier accountability.

Applications in Automotive Industry

- Interior Components – Glossy dashboards, bezels, switches.

- Exterior Trim – Black plastic bumpers, door handles, window trims.

- Decorative Parts – Piano black finishes used in premium cars.

Painted Plastic Parts – Inspection after painting to catch pinholes, orange peel, or dust contamination.

Benefits of Intelgic’s System

- Zero-Defect Manufacturing – Detects defects invisible to the human eye.

- Reduced Warranty Costs – Prevents customer complaints due to cosmetic flaws.

- Adaptability – Same system can inspect multiple part types by loading different recipes.

- Scalability – Works for both small components and large trims.

Data-Driven QC – Digital records and dashboards for audits, analytics, and supplier accountability.

Inspection of reflective automotive parts such as black plastic requires advanced lighting, optics, and AI-driven software. Traditional rule-based inspection struggles with glossy, curved surfaces, but Intelgic’s integrated machine vision solution overcomes these challenges by combining dynamic lighting geometry, robotic motion systems, and deep learning AI.

By deploying such systems, automotive manufacturers can achieve consistent quality, reduce manual dependency, and build defect-free vehicles that meet the highest customer expectations.