Automating Quality Inspection with Microscopes and Stereoscopes Using Intelgic’s Machine Vision AI

Published on: Sep 11, 2025

Written by: Content team, Intelgic

Remove Microscope and Stereoscope from your inspection workflow

Microscopes and stereoscopes have long been indispensable tools in manufacturing quality control. From PCB solder joint inspection to medical device surface analysis and precision automotive component validation, inspectors rely on magnification to detect micron-level defects invisible to the naked eye.

However, manual inspection through microscopes suffers from key limitations:

-

Inconsistency between operators

-

Fatigue-induced errors during long shifts

-

Inability to scale with high-volume production

-

Lack of traceability or digital record keeping

Intelgic transforms this process by combining high-resolution microscopy with AI-driven machine vision, enabling fully automated quality inspection and defect detection at the micro scale.

Challenges of Manual Microscopic Inspection

-

Subjectivity: Different inspectors may interpret the same defect differently.

-

Fatigue & Speed: Human eyes can miss subtle flaws during long inspections.

-

Throughput: Manual inspection is too slow for high-volume manufacturing.

-

No Digital Records: Findings are not easily logged or integrated into QC systems.

These limitations make manual methods inadequate for zero-defect manufacturing demanded by industries like electronics, medical, and aerospace.

Intelgic’s Machine Vision AI Integration with Microscopes

Intelgic has developed a system to retrofit or integrate with existing microscopes and stereoscopes. The system transforms them from visual aids for human inspectors into automated AI-driven defect detection machines.

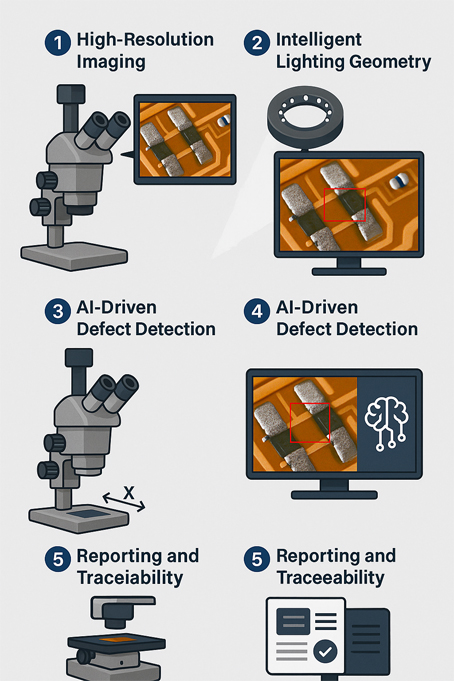

1. High-Resolution Imaging

-

Cameras mounted on microscope/scope eyepieces capture magnified images.

-

Multi-megapixel industrial cameras ensure resolution down to a few microns per pixel.

-

Autofocus modules can maintain consistent clarity across inspection cycles.

2. Intelligent Lighting Geometry

-

Ring lights, coaxial illuminators, or darkfield lighting integrated with microscopes.

-

Adaptive lighting controlled by software highlights micro-scratches, cracks, or solder anomalies.

3. AI-Driven Defect Detection

-

Intelgic’s Live Vision AI processes microscope images in real time.

-

Detects and classifies micron-level defects such as:

-

PCB solder voids, bridging, tombstoning (0201, 0402 SMDs).

-

Micro-cracks, pinholes, contamination on medical implants.

-

Coating thickness variation on optics or lenses.

-

Pits, burrs, or micro-fractures in automotive precision parts.

-

-

AI models can detect both known and unknown anomalies using supervised and anomaly detection approaches.

4. Automation & Motion Integration

-

Motorized stages can move samples under the microscope automatically.

-

X-Y scanning allows full coverage of a part without manual repositioning.

-

Multi-angle captures for 3D defect visualization.

5. Reporting and Traceability

-

Every inspection generates a Digital Quality Certificate (DQC).

-

Defect images, size (in microns), location, and classification are recorded.

-

Results integrate with MES/ERP for traceability and supplier accountability.

Advantages Over Manual Microscopic Inspection

-

Consistency – AI applies the same defect criteria every time.

-

Higher Accuracy – Detects defects down to <10 µm reliably.

-

Scalability – Continuous 24/7 inspection without fatigue.

-

Data-Driven QC – Digital storage of defect records for audits and warranties.

Adaptability – AI models can be retrained for new defect types or product designs.

Applications Across Industries

-

Electronics & Semiconductor

-

Inspection of 0201/0402 SMDs under microscope.

-

Solder joint voids, micro-cracks, bridging, and contamination.

-

-

Medical Devices

-

Micron-level inspection of stents, syringes, catheters, and implants.

-

Detects sub-10 µm cracks or surface anomalies critical for safety.

-

-

Automotive Precision Parts

-

Bearings, shafts, and black plastic reflective trims inspected under stereoscope.

-

AI highlights scratches, burrs, or surface finishing issues invisible to human eyes.

-

-

Optics and Lenses

-

Micron defect detection on transparent or coated lenses.

-

Identifies coating defects, bubbles, or scratches that degrade optical quality.

-

Intelgic’s End-to-End Solution

Unlike simple microscope-camera add-ons, Intelgic provides a turnkey inspection platform:

-

Hardware: High-resolution cameras, microscope adapters, motorized stages, and programmable lighting.

-

Software: Live Vision AI for defect detection, classification, and analytics.

-

Automation: Motion systems for multi-sample scanning.

-

Reporting: Comprehensive reports, DQC generation, and cloud/on-prem dashboards.

This combination allows manufacturers to upgrade existing inspection workflows or deploy fully automated microscopic inspection stations.

Conclusion

Microscopes and stereoscopes have always been powerful tools for quality inspection—but in the era of microelectronics, advanced medical devices, and precision automotive components, manual inspection is no longer sufficient.

By integrating Intelgic’s Machine Vision AI system with microscopes, manufacturers can achieve:

-

Micron-level defect detection

-

Automated, consistent inspections

-

Scalable throughput

-

Complete digital traceability

This transformation not only enhances inspection reliability but also drives the manufacturing industry closer to the goal of zero-defect manufacturing.