Automating Quality Inspection in High Speed Lines Using Line Scan Cameras

Published on: Feb 04, 2025

Written by: Content team, Intelgic

Automating Quality Inspection in High Speed Lines Using Line Scan Cameras

In the fast-paced world of modern manufacturing, maintaining impeccable quality standards is paramount to ensuring product reliability, minimizing defects, and maximizing operational efficiency. As automation continues to transform industrial processes, cutting-edge imaging technologies are becoming integral to quality control, particularly in high-speed production lines where traditional inspection methods fall short. Among the most sophisticated solutions available, line scan cameras stand out for their ability to capture continuous, high-resolution images with exceptional precision, making them indispensable for real-time quality assurance.

This article delves into the automation of quality inspection using line scan cameras, exploring the technical challenges of high-speed inspection, the operational principles of these advanced imaging systems, their diverse applications across various industries, and how Intelgic leverages its expertise to deliver state-of-the-art high-speed inspection solutions.

Challenges in High-Speed Line Inspection

High-speed production lines present unique challenges for quality inspection, including:

- Motion Blur – Traditional area scan cameras struggle to capture clear images of fast-moving objects, resulting in motion blur that can obscure defects.

- Lighting Issues – Consistent and uniform lighting is essential to achieve high-quality imaging, but maintaining optimal illumination across a rapidly moving surface is difficult.

- Large Surface Coverage – Inspecting wide objects, such as paper rolls, metal sheets, or textiles, requires cameras that can capture extensive surface areas without compromising resolution.

- High Data Processing Demands – Continuous scanning generates large volumes of image data, necessitating powerful image processing capabilities and real-time analysis.

- Synchronization with Production Speed – Ensuring that the camera’s scanning rate matches the conveyor belt or production line speed is crucial for accurate defect detection.

- Detection of Micro Defects – Many industries, such as semiconductor manufacturing, require microscopic defect detection, necessitating high-resolution imaging and advanced AI-driven analytics.

Understanding Line Scan Cameras and Their Working Principle

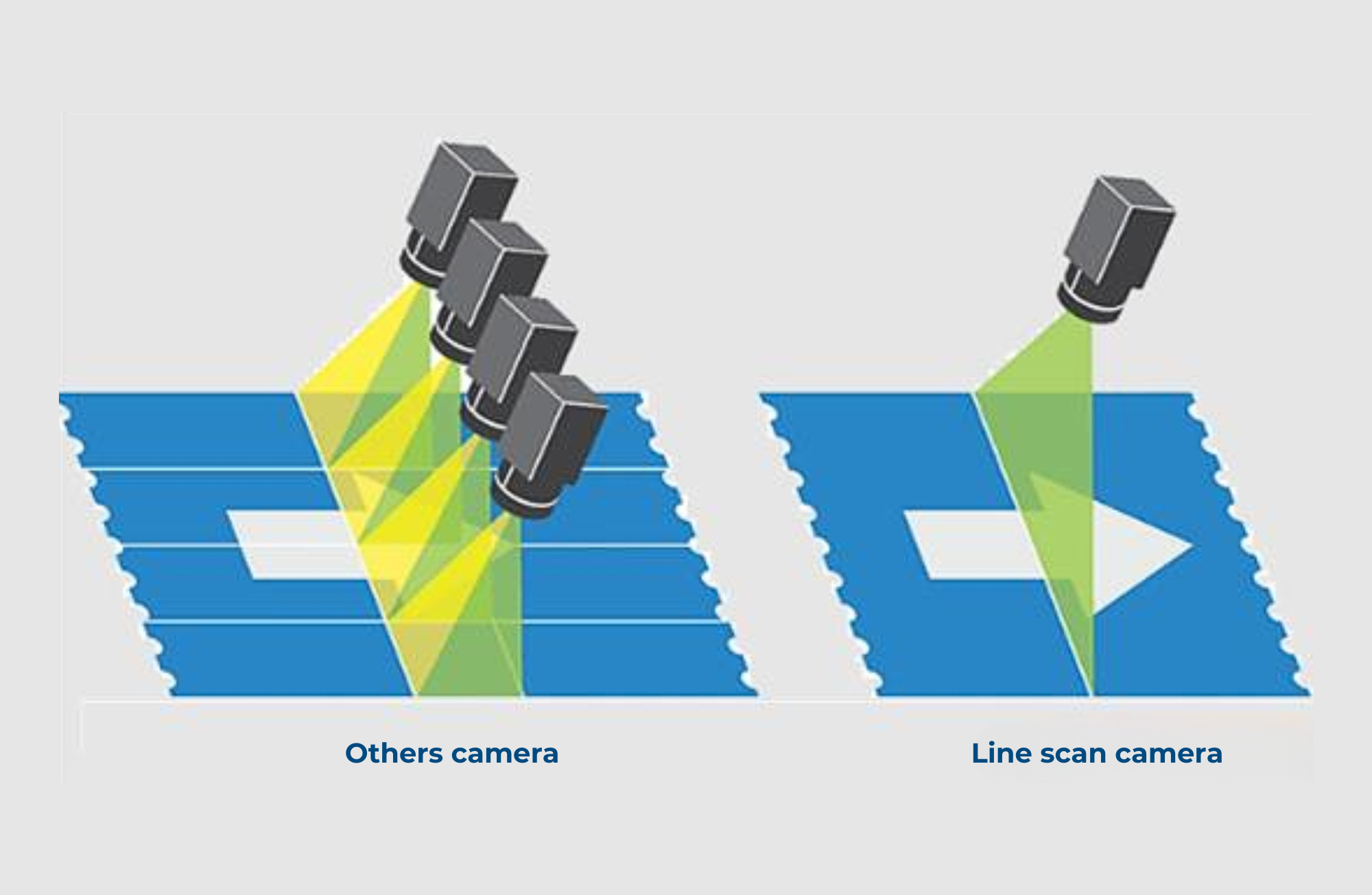

A line scan camera captures images one line at a time as an object moves past it, unlike area scan cameras that capture entire frames at once. It features a single-row pixel array that continuously scans the object, with precise synchronization to the motion of a conveyor belt or moving system. As multiple lines are captured sequentially, real-time software stitches them together to form a high-resolution image. Advanced AI and machine vision algorithms analyze these images instantly, detecting defects, inconsistencies, or variations with high precision.

How Line Scan Cameras Work in High Speed Production Lines

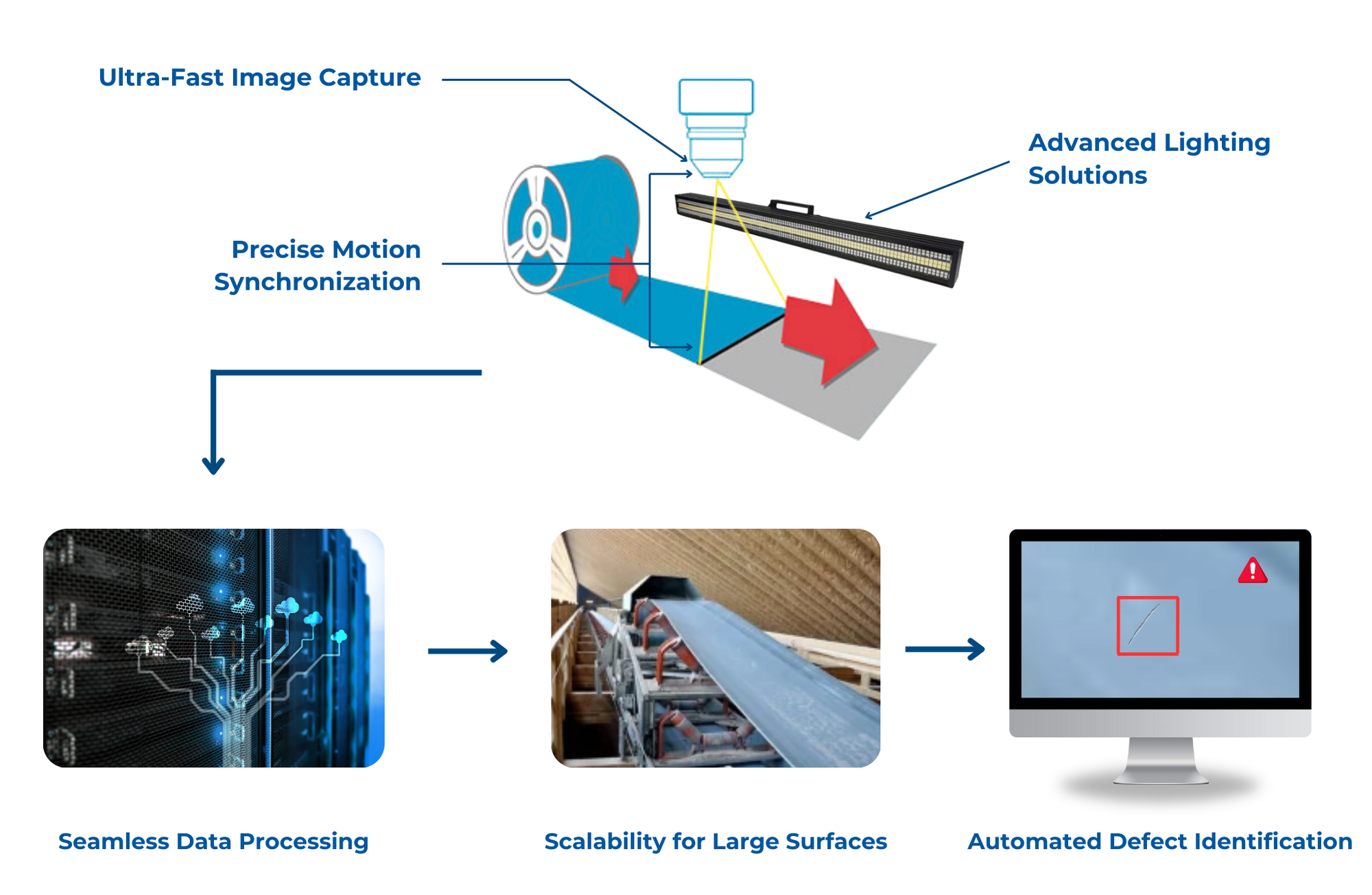

In high-speed production environments, line scan cameras provide exceptional accuracy and efficiency by continuously capturing detailed images of moving objects. Their ability to operate at extremely high frame rates ensures seamless quality inspection without disrupting production flow. Here’s how they work in such demanding conditions:

- Ultra-Fast Image Capture – With high line rates, often exceeding 100,000 lines per second, line scan cameras can keep up with rapid production speeds without missing details.

- Precise Motion Synchronization – Encoders and motion control systems ensure that the camera’s scanning rate perfectly matches the speed of conveyor belts or rollers, preventing misalignment in the captured image.

- Advanced Lighting Solutions – In high-speed line inspection, a line scan camera integrates with an advanced lighting system to ensure optimal image quality. The lighting system, such as LED line lights, provides consistent illumination across the moving object, while the line scan camera captures high-resolution images in real-time. This integration enables precise defect detection, even at high speeds, by eliminating shadows and reflections, ensuring clear, accurate images for efficient inspection.

- Seamless Data Processing – The vast amount of image data generated is processed in real-time using powerful AI-driven analytics, enabling instant defect detection and quality assessment.

- Scalability for Large Surfaces – Multiple line scan cameras can be synchronized to cover wider surfaces, ensuring complete inspection of large products such as paper rolls, textiles, or metal sheets.

- Automated Defect Identification – AI algorithms analyze high-resolution images instantly, flagging defects like surface irregularities, misprints, or structural inconsistencies without manual intervention.

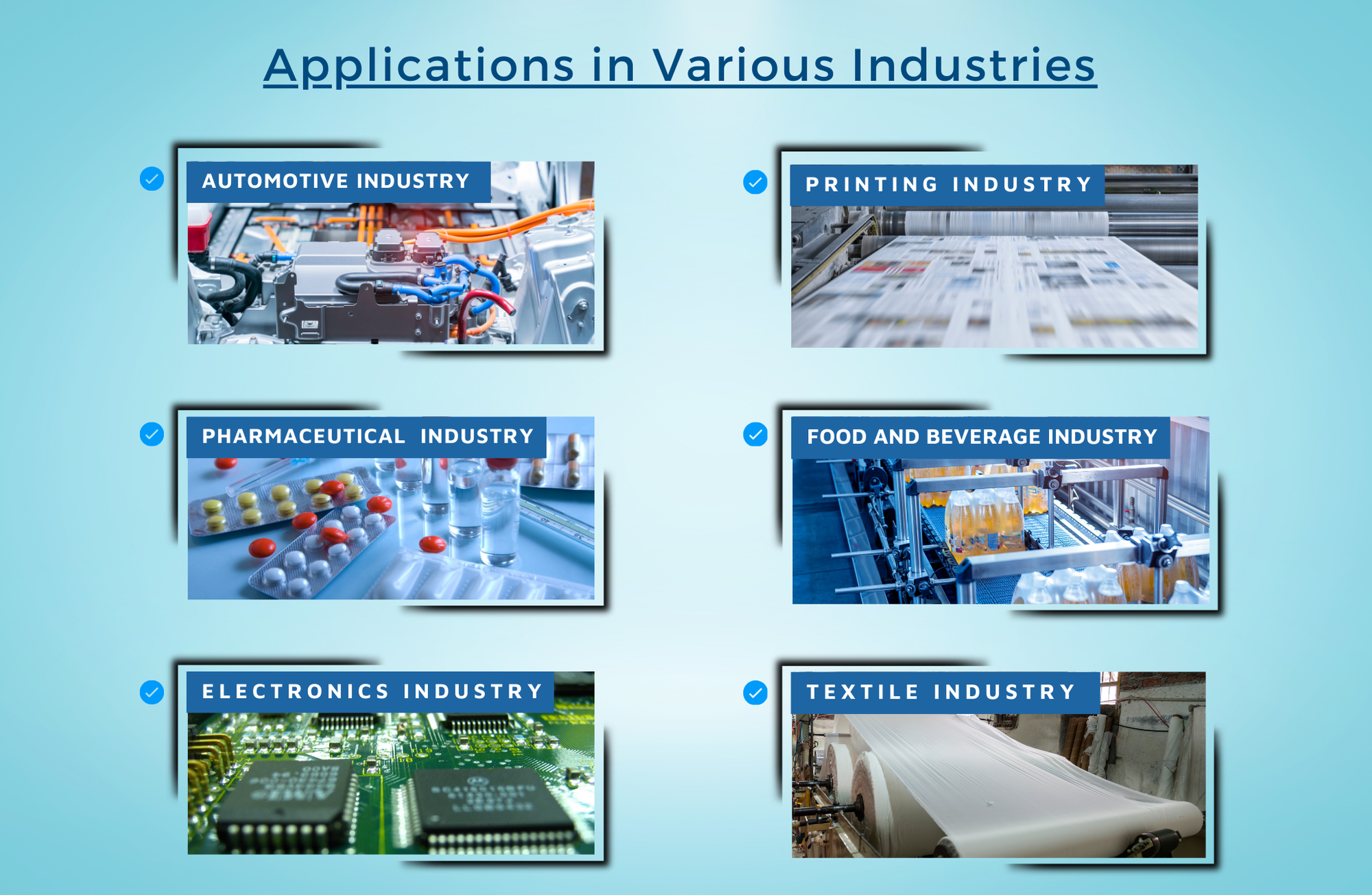

Applications in Various Industries for High Speed Line

Line scan cameras have extensive applications across various industries due to their high-speed, high-precision imaging capabilities:

- Automotive Industry

- Inspection of paint defects on vehicle bodies.

- Quality control for metal sheet processing.

- Tire tread inspection for consistency and safety compliance.

- Pharmaceutical and Medical Industry

- Inspection of blister packs and labels.

- Detecting defects in syringes, vials, and ampoules.

- Monitoring tablet coating uniformity.

- Electronics and Semiconductor Industry

- Identifying microcracks in PCBs.

- Ensuring solder joint integrity in microchips.

- Verifying alignment of semiconductor wafers.

- Printing and Packaging Industry

- Inspection of high-speed printing processes to detect smudging or misalignment.

- Ensuring barcodes and QR codes are printed correctly.

- Verifying labels for pharmaceutical and consumer goods packaging.

- Food and Beverage Industry

- Detecting contamination in processed foods.

- Verifying uniformity in packaging and sealing.

- Ensuring proper label placement and legibility.

- Textile and Paper Industry

- Inspection of fabric consistency in textile manufacturing.

- Detecting paper roll defects such as tears or uneven coatings.

- Monitoring print quality in newspapers and magazines.

Intelgic's Expertise in High-Speed Line Inspection

Intelgic is at the forefront of high-speed quality inspection automation, leveraging cutting-edge line scan camera technology and AI-driven analytics to optimize industrial processes. Here’s how Intelgic stands out in this domain:

- AI-Powered Defect Detection: Detects minute defects with high accuracy, reducing false positives.

- Seamless Integration: Easily integrates into existing production lines, minimizing downtime.

- High-Speed Data Processing: Ensures real-time analysis without delays.

- Customized Solutions: Tailored to meet specific industry needs for peak performance.

- Scalability: Solutions scale with production volume, maintaining high quality.

- User-Friendly Interface: Intuitive dashboard for real-time monitoring and analytics.

- Enhanced Lighting: Specialized lighting techniques improve image contrast and accuracy.

- Predictive Maintenance: AI provides insights to help prevent costly downtime.

Automating quality inspection in high-speed production lines with line scan cameras revolutionizes defect detection, ensuring precision and efficiency. Overcoming challenges like motion blur, data processing, and synchronization is key to achieving optimal results. With AI-powered analytics and continuous scanning, line scan cameras provide unparalleled accuracy across industries. Intelgic enhances this technology with cutting-edge AI, seamless integration, and high-speed data processing, making it a trusted partner in quality control. As industries embrace automation, Intelgic empowers businesses to boost productivity, maintain consistent quality, and drive operational excellence