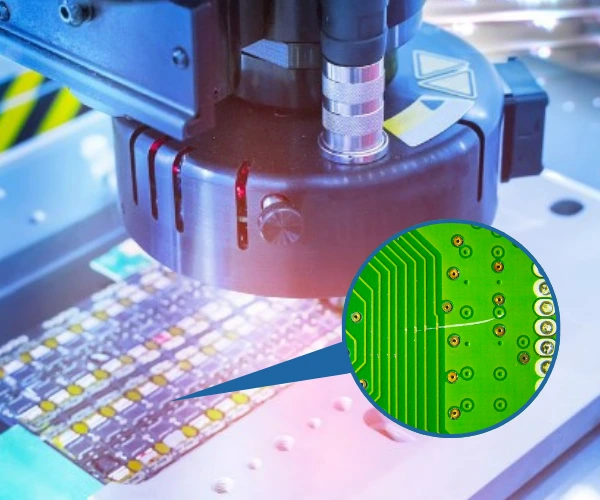

Automate Inspection processes using machine vision imaging and AI

Intelgic, a Utah-based company, specializes in providing cutting-edge Automated Optical Inspection (AOI) systems and machine vision solutions to manufacturers across Utah and other states of the United States. Our mission is to empower businesses with advanced technologies that automate inspection processes, enhance defect detection, and improve overall production efficiency.

From precision-based industries like aerospace and medical devices to high-volume manufacturing in automotive and consumer goods, Intelgic’s AOI systems are designed to meet the unique demands of every sector. With expertise in AI-powered inspection software, customized imaging solutions, and fully integrated automation systems, we help manufacturers achieve the highest standards of quality control.