Automated Inspection System for Windshield Quality Check

Published on: Sep 24, 2025

Written by: Content team, Intelgic

Introduction

Automotive windshields are critical for both structural integrity and driver visibility, making their quality a top priority in vehicle manufacturing. However, windshields pose unique challenges for inspection due to their size, curved shape, transparency, and the nature of potential defects—many of which are microscopic or angle-dependent.

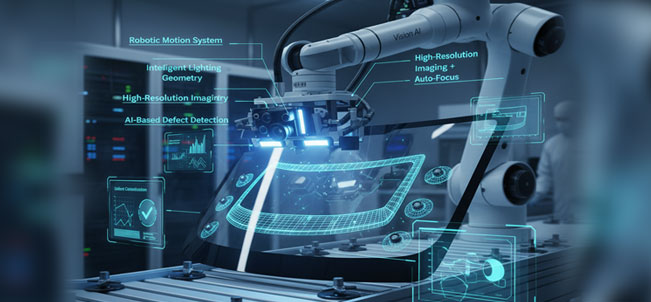

To address these complexities, Intelgic provides a fully automated inspection system that uses robotic motion platforms, high-resolution imaging, and intelligent lighting control, combined with AI-driven defect detection software. This system ensures that every windshield meets stringent quality standards before reaching the assembly line.

Challenges in Windshield Inspection

Inspecting automotive windshields is not as straightforward as inspecting flat, opaque surfaces. Several challenges make manual inspection inefficient and error-prone:

Large Surface Area

Windshields are wide and tall components, making it difficult to inspect every zone uniformly without automation.

Curved Geometry

Unlike flat glass, windshields have 3D curvature, causing variation in focus distance, light reflection, and camera angle.

Defects Invisible at Normal Angles

Many defects like micro-scratches, delamination, or surface waviness are only visible under specific lighting angles or intensities.

Transparency and Reflection

Windshields reflect ambient light and background objects, often masking small defects during human inspection.

Intelgic’s Robotic Inspection Solution

To solve these problems, Intelgic has developed a robotic, machine-vision-based inspection system tailored for windshield quality assurance.

Robotic Motion System for Dynamic Imaging

Intelgic uses multi-axis robotic arms or motorized rails to:

- Move the imaging system (camera + lights) across the entire surface of the windshield

- Adjust the camera position and angle based on the curvature of the glass

- Maintain optimal working distance for sharp focus on all surface areas

Intelligent Lighting Geometry

- Specialized lighting setups (low-angle ring lights, dome lights, oblique illumination) are used

- Lighting angle and intensity are dynamically adjusted based on local surface curvature

- This allows visibility of angle-dependent defects like:

- Scratches

- Contaminants

- Edge cracks

- Waviness and distortions

- Scratches

High-Resolution Imaging + Auto-Focus

- Intelgic integrates industrial cameras (20–65MP) with precision lenses

- Cameras are auto-focused or repositioned in real-time as the robot moves across varying curvature

AI-Based Defect Detection

Using Intelgic’s proprietary Live Vision AI platform, the system performs:

- Surface defect detection (scratches, chips, pits, inclusions)

- Edge integrity check

- Optical distortion mapping

- Comparative analysis against golden reference models

- Defect classification by type, location, and severity

What the System Detects

|

Defect Type |

Description |

|

Scratches & Abrasions |

Micro or macro scratches from handling or polishing |

|

Contaminants or Inclusions |

Dust, bubbles, or foreign particles in the glass |

|

Delamination |

Separation or clouding in laminated windshields |

|

Optical Distortion |

Waviness affecting driver vision |

|

Edge Defects |

Cracks, chips, or improper curvature at the edges |

|

Uneven Coating / Films |

Detection of coating uniformity (e.g., tint layers) |

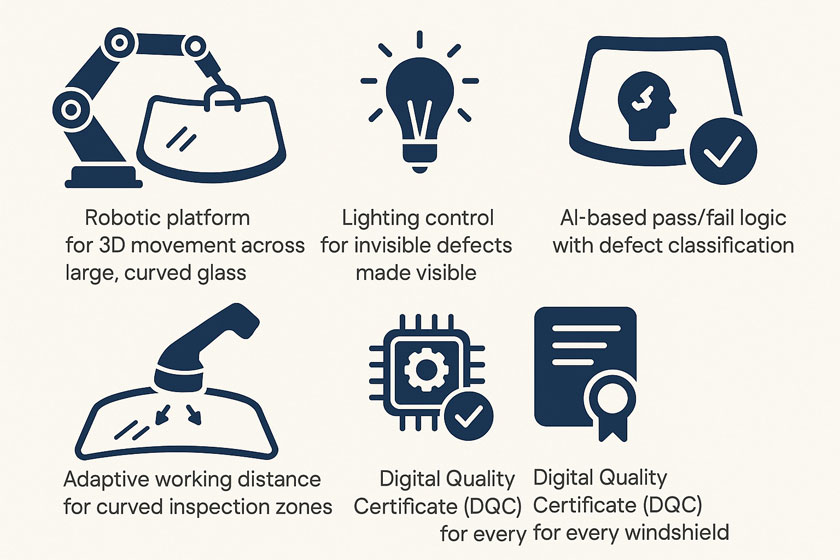

System Highlights

- Robotic platform for 3D movement across large, curved glass

- Lighting control for invisible defects made visible

- Adaptive working distance for curved inspection zones

- AI-based pass/fail logic with defect classification

- Comprehensive inspection reports with high-res images

- Digital Quality Certificate (DQC) for every windshield

Full Turnkey Solution from Intelgic

Intelgic delivers a complete, ready-to-deploy system including:

- Robotic motion platform

- Vision system (cameras, lenses, lighting)

- Mounting and adjustment fixtures

- AI software and inspection dashboard

- PLC/MES integration

- Installation, training, and support

Benefits to Manufacturers

✔ Improved quality control with zero human error

✔ Early defect detection to reduce rework and waste

✔ Higher throughput without compromising on inspection depth

✔ Regulatory compliance with full inspection traceability

✔ Scalable for different windshield types and vehicle models

Conclusion

Inspecting windshields requires more than just a camera—it requires intelligence, adaptability, and precision. Intelgic’s robotic inspection system brings together all the technologies needed to inspect curved, transparent glass surfaces with speed and accuracy.

From scratch detection to distortion analysis, Intelgic helps manufacturers ensure visual clarity, structural integrity, and regulatory compliance for every windshield.

📩 Contact Intelgic today to learn how we can automate your windshield inspection process.