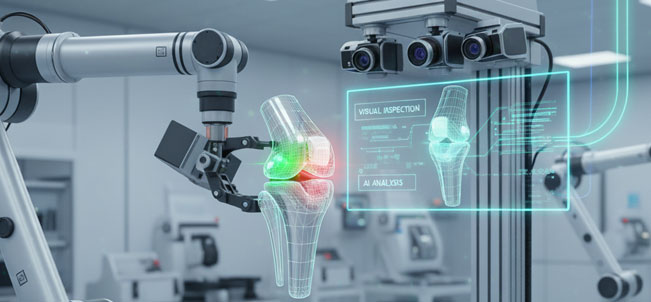

Automating Visual Inspection of Artificial Knee Implants Using Machine Vision and AI

Published on: Oct 08, 2025

Written by: Content team, Intelgic

Artificial knee implants are life-changing medical devices, restoring mobility and quality of life for millions of patients worldwide. Given their critical application in the human body, these implants must be manufactured with extreme precision, free from even the smallest visual defects or dimensional inaccuracies.

Traditional inspection processes for knee implants are often manual, relying on trained inspectors to visually check surfaces for flaws. However, human inspection is inherently limited—subjective, inconsistent, and unable to reliably detect micro-level defects across complex 3D geometries.

To address these challenges, manufacturers are turning to machine vision and AI-powered automation to ensure 100% inspection accuracy, faster throughput, and full traceability. In this article, we explore how Intelgic’s advanced visual inspection systems are transforming the way artificial knee implants are inspected.

Why Artificial Knees Are Challenging to Inspect

Artificial knees (typically made of cobalt-chrome alloy, titanium, or ceramic-polymer composites) come with a host of inspection complexities:

- Shiny and reflective surfaces create glare and uneven lighting during imaging

- Irregular 3D geometry including curves, cavities, and undercuts are hard to inspect uniformly

- Critical surface finish requirements, where scratches, pits, and discoloration can impact biocompatibility or patient safety

- Tight dimensional tolerances in the range of 10–30 microns

- Surface coating (e.g., hydroxyapatite, ceramic) must be evenly applied and defect-free

These factors make artificial knees ideal candidates for automated, high-precision inspection systems.

Intelgic’s Visual Inspection Automation System for Artificial Knee Implants

Intelgic designs custom turnkey systems specifically for complex medical implants like artificial knees. These systems combine:

- Industrial machine vision cameras

- Specialized lighting systems

- Robotic motion or multi-axis positioning platforms

- Advanced optics (telecentric, zoom, or liquid lenses)

- AI-driven inspection software

- Reporting and traceability tools

Let’s break down the system components and inspection process.

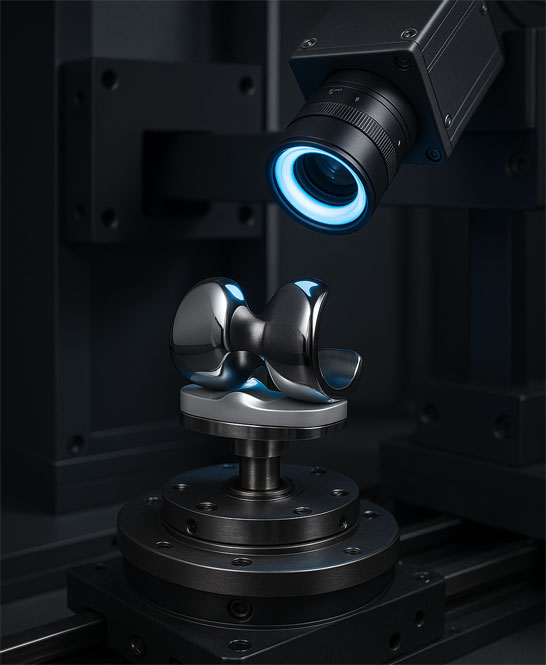

1. Imaging Hardware Optimized for Shiny, Complex Surfaces

Intelgic’s system uses area scan or line scan cameras with up to 65 MP resolution, depending on part size and inspection detail. To capture all surfaces:

- Machine vision cameras are positioned at strategic angles

- Motorized rotation and tilt mechanisms move the knee implant during inspection

Fully automated inspection system including motion system, vision system and analytics

2. AI-Based Surface Defect Detection

Intelgic’s Live Vision AI software is trained on thousands of annotated images of knee implants to identify:

- Scratches, scuffs, and tool marks

- Pitting, surface porosity, or material inconsistencies

- Coating defects, delamination, or uneven spray patterns

- Color anomalies, discoloration, or burn marks

- Polishing quality and mirror-finish consistency

AI models classify each defect by type, location, severity, and pass/fail criteria based on custom acceptance thresholds.

3. Automated Reporting & Traceability

Each inspected implant is logged in the system with:

- Annotated image sets for full visual traceability

- Defect classification and severity scoring

- Pass/Fail decision with acceptance criteria

- Digital Quality Certificate (DQC)

- Data export to MES/ERP/QMS systems

- Cloud dashboard (optional) for shift-wise, part-wise analytics

All results are stored for compliance with FDA, ISO 13485, and CE Mark requirements.

4. Integration with Manufacturing Workflow

Intelgic’s system can be deployed as:

- Inline inspection integrated directly into the machining or polishing cell

- Offline workstation, where operators load parts onto a rotating stage

- Robotic loading/unloading systems for higher throughput and operator-free inspection

Cleanroom-compatible variants for aseptic manufacturing environments

Benefits of Intelgic’s Knee Implant Inspection System

|

Benefit |

Description |

|

🎯 Micron-Level Accuracy |

Detects defects below 10 µm reliably |

|

⚡ High-Speed Automation |

Short inspection cycles improve productivity |

|

🔁 Repeatability |

Consistent inspection across all shifts, no fatigue |

|

📋 Compliance Ready |

Supports audit trails, traceability, and quality documentation |

|

🧠 Intelligent AI Models |

Adapt to new defect types and reduce false positives |

Ensuring Implant Quality with Vision AI

The future of medical device manufacturing is digital and intelligent. With rising quality standards and zero-defect goals, manual inspection is no longer enough—especially for life-critical devices like artificial knees.

Intelgic’s customized AI-based visual inspection system provides manufacturers with the tools to:

- Detect defects invisible to the human eye

- Eliminate rework and recall risks

- Increase efficiency and throughput

- Ensure full regulatory compliance

By combining machine vision, robotic precision, and deep-learning AI, Intelgic helps manufacturers deliver implants that meet the highest global standards—every time.