AI-Powered Wooden Panel Hole Detection Positioning and Dimension Measurement

Published on: Feb 17, 2025

Written by: Content team, Intelgic

AI-Powered Wooden Panel Hole Detection, Positioning and Dimension Measurement

Ensuring the quality of wooden panels is essential in industries such as furniture manufacturing, construction, and flooring. Traditional inspection methods, which rely on manual labor, often lead to inconsistencies and inefficiencies. However, advancements in artificial intelligence (AI) and camera-based vision systems have enabled automated and precise quality control.

This article explores how AI-driven machine vision systems identify holes, determine their exact positions, and measure dimensions with exceptional accuracy. It also discusses the technologies, challenges, benefits, and real-world applications of AI-powered wooden panel inspection.

Challenges in Wooden Panel Hole Inspection:

- Surface Variability: Wood has natural grain patterns, knots, and color variations that can interfere with hole detection.

- Panel Warping or Bending: Warped panels can cause misalignment in detected hole positions.

- Misalignment on Conveyor: If the panel is not aligned properly during scanning, hole positions may be inaccurately mapped.

- Variation in Panel Size: Different panel dimensions can lead to difficulty in standardizing hole placement detection.

- Small Hole Detection: Accurately measuring small holes can be challenging due to resolution limitations of cameras/sensors.

- Depth Measurement: Flat 2D imaging may not accurately capture the depth of holes.

- Processing Speed: High-speed production lines require rapid and accurate hole detection, which may challenge real-time processing capabilities.

Machine Vision AI:Wooden Panel Hole Inspection

1. Image Acquisition Using High-Resolution Cameras

AI-powered inspection begins with capturing detailed images of the wooden panels using:

- Machine Vision cameras with high-resolution sensors for detecting fine details.

- Infrared cameras to identify subsurface defects invisible to the naked eye.

- 3D laser scanning for precise three-dimensional mapping of the panel.

Strategically positioned cameras ensure full coverage of the panel’s surface for comprehensive analysis.

2. Advanced Illumination in AI-Based Inspection

Lighting plays a crucial role in achieving accurate inspection results. Advanced illumination techniques improve defect detection by enhancing contrast and reducing shadows. Key illumination methods include:

- Structured Light Illumination: Projects a controlled light pattern onto the panel surface to enhance texture visibility and defect detection.

- Diffuse LED Lighting: Reduces glare and provides uniform brightness for improved image clarity.

- Multi-Angle Illumination: Uses different light angles to highlight surface irregularities and holes.

3. AI Algorithms for Defect Detection

AI-based vision systems employ deep learning and computer vision techniques to analyze images. The process includes:

- Image Preprocessing: Enhancing contrast, reducing noise, and sharpening edges for improved analysis.

- Object Detection: Identifying holes, cracks, and other imperfections based on learned patterns and anomalies.

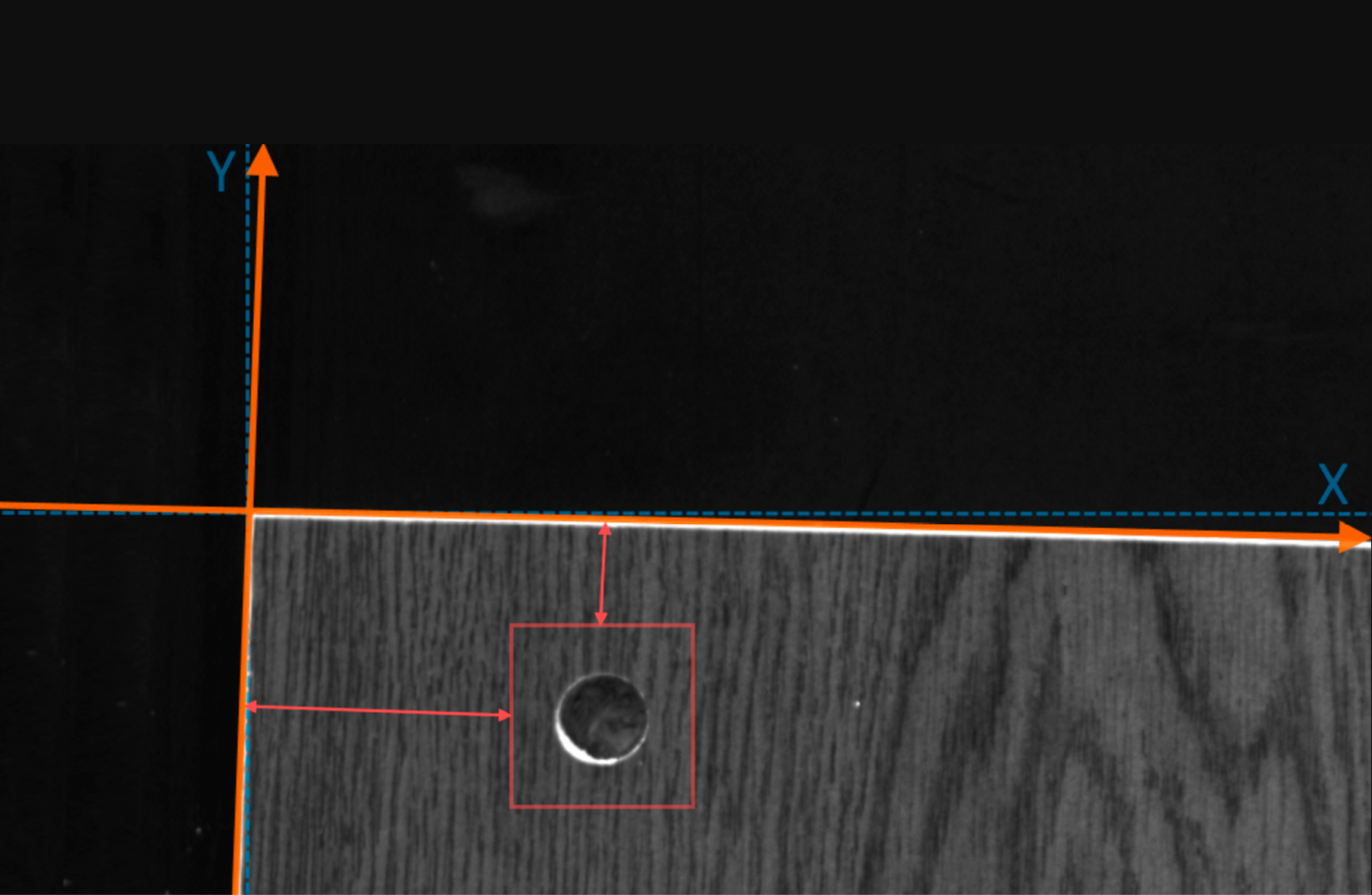

- Positioning Analysis: Determining the exact coordinates of holes and comparing them to design blueprints.

- Dimension Measurement: Extracting accurate dimensions such as panel length, width, and hole diameters with sub-millimeter precision.

4. Machine Learning for Continuous Improvement

AI models are trained on extensive datasets containing images of wooden panels with various defects. This enables them to:

- Differentiate between natural wood patterns and actual defects.

- Improve detection accuracy by learning from previous inspections.

- Adapt to variations in lighting, wood textures, and environmental conditions for consistent results.

Workflow for Wooden Hole Measurement

AI-powered vision systems follow a structured workflow to measure holes accurately:

- Image Capture: High-resolution cameras scan the wooden panel from multiple angles.

- Preprocessing: The system enhances image quality by reducing noise and optimizing contrast.

- Edge Detection: AI algorithms identify hole boundaries using advanced contour detection techniques.

- Shape Recognition: The system classifies detected holes based on predefined geometric parameters.

- Position Mapping: The precise coordinates of each hole are mapped to reference points to ensure proper placement.

- Dimension Calculation: AI measures hole diameters, depths, and alignment using pixel-to-millimeter calibration.

- Comparison with Design Specifications: The measured values are matched against predefined tolerances to identify any deviations.

- Quality Assessment: Any inconsistencies are flagged for further inspection or correction.

- Report Generation: The system logs inspection data for analysis and process optimization.

Benefits of AI-Driven Wooden Panel Inspection

- Superior Accuracy and Precision:AI algorithms can detect and measure defects with sub-millimeter precision, reducing human error and ensuring consistent quality.

- Faster Inspection Processes:Automated inspections significantly reduce inspection time compared to manual checks, enhancing production efficiency.

- Cost Savings:AI-driven inspection minimizes material wastage and labor costs, ultimately lowering operational expenses.

- Real-Time Monitoring and Reporting:Instant feedback and automated reporting allow for quick corrective actions, improving overall quality control.

- Scalability and Flexibility:AI-powered systems can be adapted to different panel sizes, shapes, and materials, making them suitable for diverse industries.

Applications of AI-Powered Wooden Panel Inspection

1. Furniture Manufacturing:Ensuring accurate hole placements and dimensions enhances the quality and durability of wooden furniture components.

2. Construction Industry:Accurate dimension measurement ensures the proper fit of wooden panels used in walls, ceilings, and flooring.

3. Flooring Industry:Detecting surface defects and incorrect dimensions maintains high product standards in wooden flooring production.

4. Plywood and Veneer Production:AI-driven inspection ensures consistency in plywood sheets, reducing defects and improving material efficiency.

Future of AI in Wooden Panel Inspection

As AI and computer vision technologies continue to evolve, several key trends are shaping the future of wooden panel inspection:

- Enhanced 3D Vision Systems: Improved 3D imaging for more accurate defect detection and depth analysis.

- AI-Powered Robotics: Automated robotic systems integrated with AI for seamless inspection and quality control.

- Cloud-Based Data Analytics: AI-driven insights for predictive maintenance and continuous quality improvements.

- Edge AI for Real-Time Processing: On-device AI processing for faster and more efficient defect detection.

Conclusion

AI powered Machine Vision systems are revolutionizing wooden panel inspection by increasing accuracy, efficiency, and cost-effectiveness. By detecting holes, measuring dimensions, and identifying defects with unmatched precision, AI ensures superior product quality across industries such as furniture manufacturing, construction, and flooring.

As AI and computer vision technologies continue to evolve, businesses must embrace these advancements to maintain competitive quality standards. Intelgic, a leader in AI-driven automation solutions, specializes in developing cutting-edge vision systems tailored to industrial inspection needs. With expertise in AI-powered defect detection and dimensional analysis, Intelgic helps manufacturers achieve unparalleled efficiency and accuracy in quality control.

Take your inspection process to the next level—contact Intelgic today to explore AI-driven solutions for your business!