Automating Door Panel and Wooden Panel Inspection with Machine Vision AI

Published on: Feb 25, 2025

Written by: Soumen das

Introduction

In most manufacturing plants, wooden panel and door panel inspection is still performed manually, making the process slow, error-prone, and inconsistent. Quality defects such as surface imperfections, incorrect hole placements, missing inserts, and dimensional deviations can impact product durability, aesthetics, and customer satisfaction.

With the advancement of Machine Vision AI and Automated Optical Inspection (AOI) systems, manufacturers can now automate high-speed, accurate, and real-time inspection of wooden panels and door panels. AI-powered inspection systems, equipped with high-resolution cameras, line scan imaging, and deep learning algorithms, ensure that every panel meets predefined quality standards before moving to the next stage of production.

Challenges in Manual Wooden Panel Inspection

- Human Error and Subjectivity

- Manual inspection depends on the experience of human inspectors, leading to inconsistent results.

- Some defects are too small or subtle to be detected reliably by the human eye.

- Time-Consuming and Labor-Intensive

- Factories producing large volumes of wooden panels cannot efficiently inspect every panel manually.

- Surface Defect Detection is Inconsistent

- Minor scratches, dents, or grain inconsistencies are often overlooked, leading to quality control issues.

- Verifying Hole Placement and Inserts is Tedious

- Counting the number of holes and checking insert placement requires precision, which is difficult to maintain in manual inspections.

- Dimensional Accuracy Requires Precision Measurement

- Measuring panel dimensions and ensuring compliance with golden templates (predefined standard templates) is a complex process.

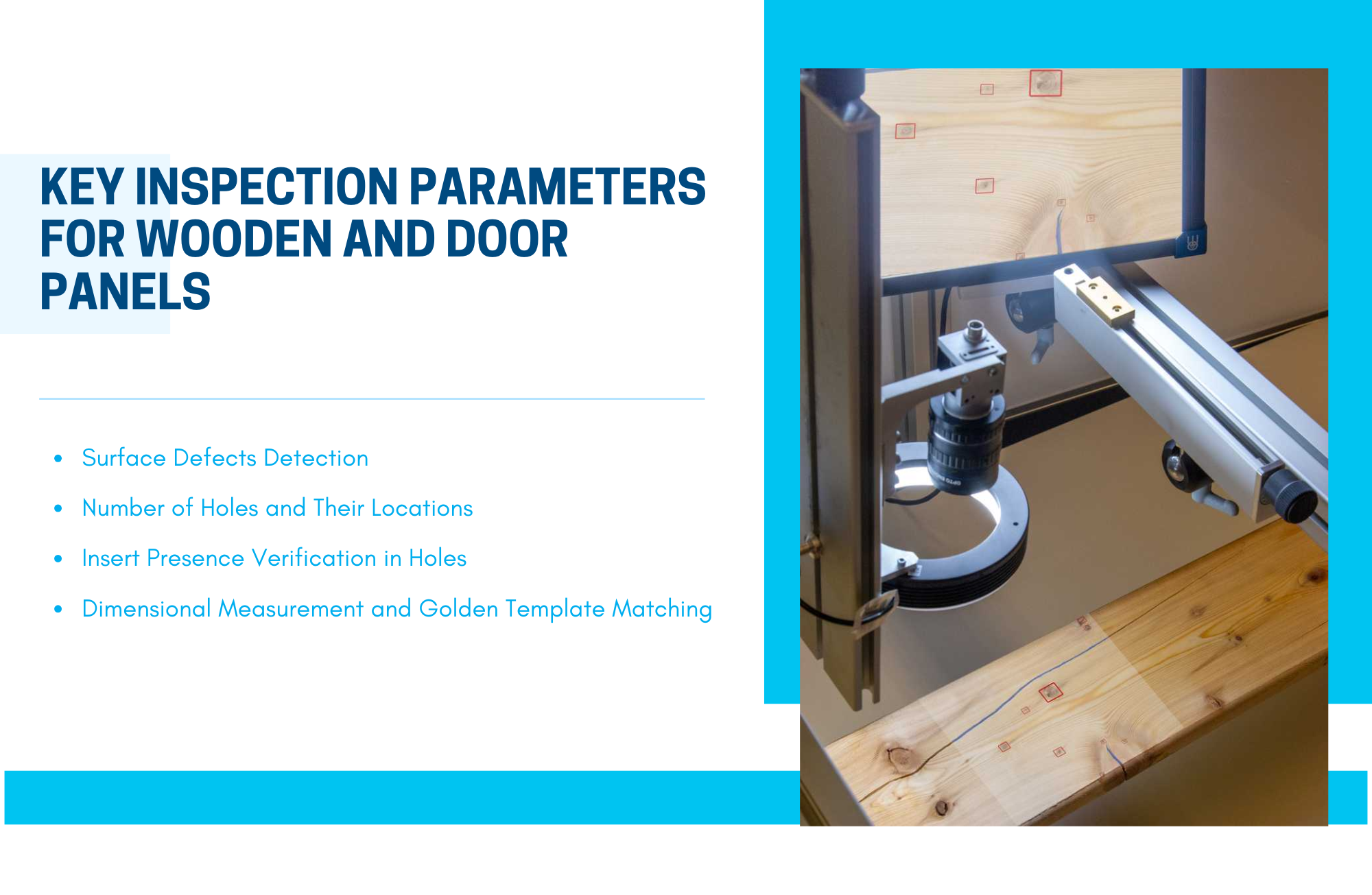

Key Inspection Parameters for Wooden and Door Panels

An effective AI-powered AOI system automates the detection of four major quality aspects:

1. Surface Defects Detection

- The system scans the entire panel surface for defects such as:

Scratches

Dents

Patches

Warping and uneven coatings - AI-driven deep learning models compare the scanned panel to an Golden template and flag any anomalies.

2. Number of Holes and Their Locations

- Wooden panels and door panels require pre-drilled holes for screws, hinges, and assembly.

- The AOI system verifies:

The exact number of holes in the panel.

The precise location of each hole according to predefined design specifications. - If a hole is missing, misplaced, or oversized, the system flags the defect.

3. Insert Presence Verification in Holes

- Many door panels require metal or plastic inserts inside pre-drilled holes.

- The AI system detects:

Whether an insert is present in each hole.

If the insert is correctly placed or missing. - Defective panels with missing inserts can be automatically sorted out.

4. Dimensional Measurement and Golden Template Matching

- Each panel must match precise length, width, and thickness specifications.

- The AOI system performs:

Real-time dimensional measurement using high-precision cameras.

Golden template comparison to ensure every panel meets its design specifications.

Tolerance verification to check whether minor deviations are within acceptable limits.

Automating Wooden Panel Inspection Using AOI and Machine Vision AI

The automated optical inspection (AOI) system integrates high-speed line scan cameras, specialized lighting, and AI software to inspect wooden panels efficiently.

1. High-Speed Line Scan Cameras for Continuous Inspection

- In a fast-moving production line, line scan cameras capture images line-by-line as the panel moves.

- This ensures high-resolution imaging of the entire panel surface, even at high speeds.

- Multiple cameras can be used to inspect panels from different angles.

2. AI-Powered Defect Detection and Image Processing

- AI models analyze high-resolution images to detect surface defects, missing holes, and misalignments.

- AI can distinguish between acceptable natural wood patterns and actual defects to avoid false positives.

3. Industrial Lighting for Better Contrast and Visibility

- Proper lighting is critical for capturing fine details and minimizing shadows or reflections.

- Diffuse lighting enhances surface contrast, making scratches, dents, and texture inconsistencies more visible.

4. Encoder-Based Speed Synchronization for Accuracy

- When the production line speed varies, encoders synchronize the camera triggering rate, ensuring precise image capture without motion blur.

5. Automated Sorting and Reporting

- Accepted panels move forward for further processing.

- Rejected panels are automatically sorted or flagged for review.

- The system generates detailed reports with images and defect classifications for quality assurance tracking.

Advantages of Using AI-Powered AOI for Wooden Panel Inspection

Eliminates Human Errors and Improves Accuracy

- Ensures consistent quality control across all panels.

Increases Inspection Speed and Production Efficiency

- Inspects panels in real-time without slowing down production.

Reduces Waste and Improves Material Utilization

- Identifies defects early, preventing defective products from moving to later stages.

Enhances Customer Satisfaction with High-Quality Products

- Ensures zero defects in finished door panels and wooden panels.

Reduces Costs Associated with Manual Inspection

- Saves labor costs and minimizes material rejection.

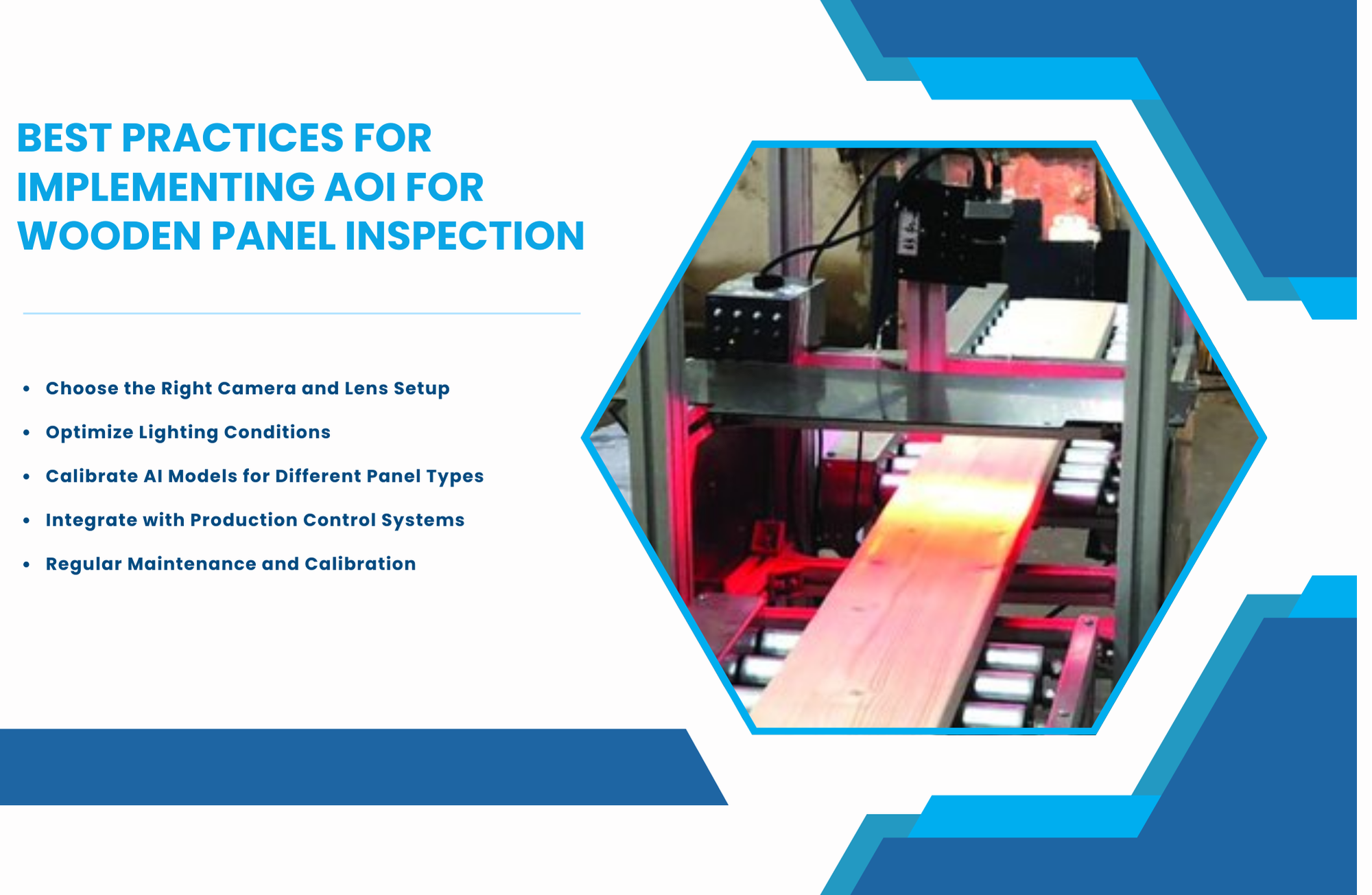

Best Practices for Implementing AOI for Wooden Panel Inspection

- Choose the Right Camera and Lens Setup

- Select high-resolution line scan cameras for real-time continuous inspection.

- Use multiple cameras for full panel coverage.

- Optimize Lighting Conditions

- Use diffuse lighting for surface defect detection.

- Ensure consistent brightness to prevent false defect detection.

- Calibrate AI Models for Different Panel Types

- Train AI algorithms with diverse samples of panels to improve defect classification.

- Integrate with Production Control Systems

- Ensure seamless connectivity with Manufacturing Execution Systems (MES) for automated reporting.

- Regular Maintenance and Calibration

- Perform routine calibration of cameras, sensors, and encoders for optimal performance.

Automating door panel and wooden panel inspection with Machine Vision AI and AOI systems ensures high accuracy, speed, and efficiency in defect detection. By leveraging high-resolution line scan cameras, AI-powered defect analysis, and industrial lighting, manufacturers can eliminate human errors, reduce production waste, and improve overall quality control.

Intelgic’s AI-powered AOI system provides a fully automated, scalable, and highly accurate solution for wooden panel inspection. Whether you need to inspect surface defects, hole placement, inserts, or dimensions, our cutting-edge machine vision technology ensures a flawless production process.

Get Started with Intelgic Today!

📞 Contact us for a custom AI-powered AOI solution for your manufacturing needs!