Why High FPS Cameras Are Essential for Small Part Counting on High-Speed Lines

Published on: Dec 30, 2024

Written by: Content team, Intelgic

Why High FPS Cameras Are Essential for Small Part Counting on High-Speed Lines

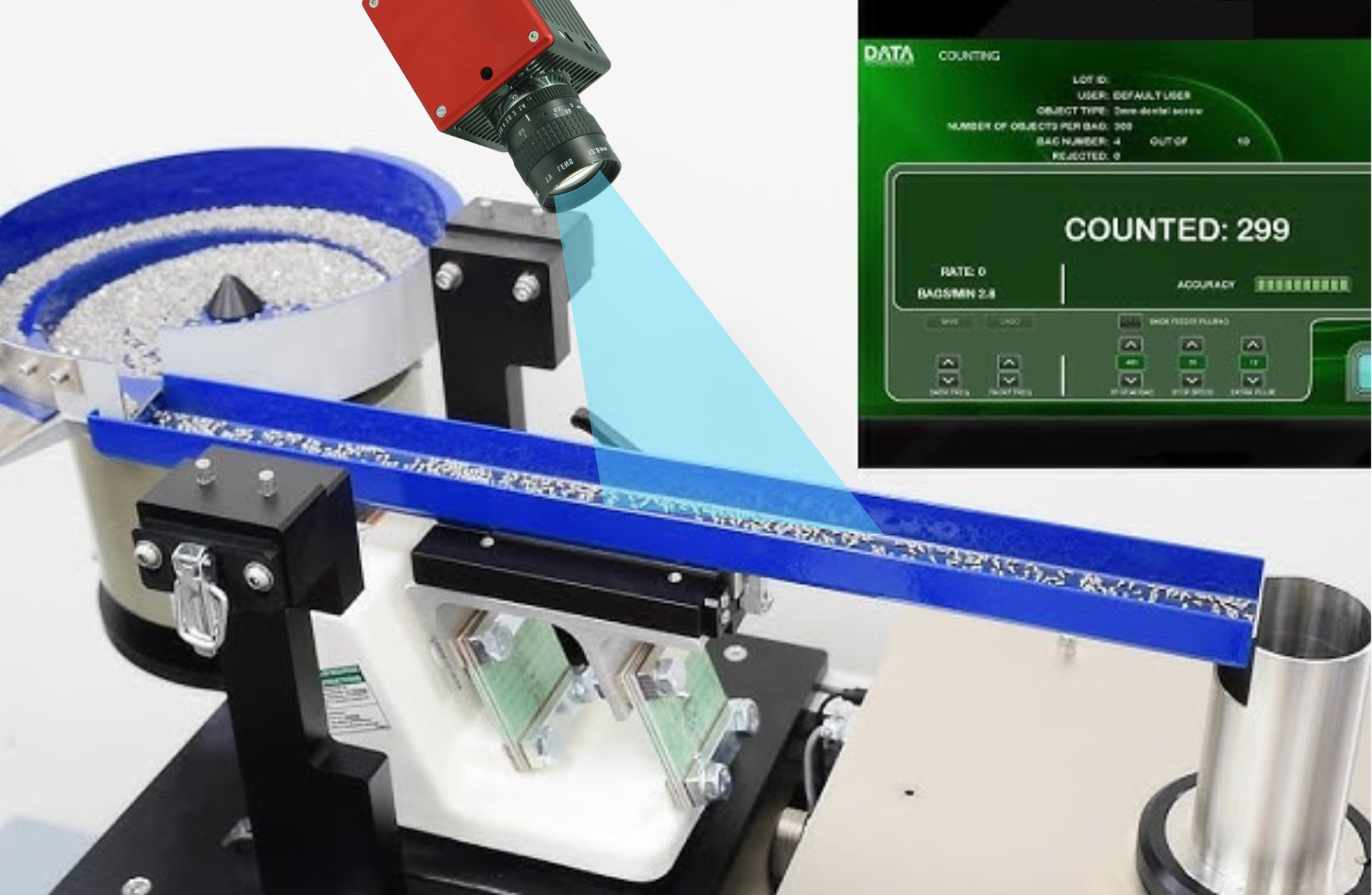

In high-speed production environments, accurately counting small parts on a moving conveyor requires precision and efficiency. One critical factor for success is the selection of a camera with an appropriate Frames Per Second (FPS) rate. High FPS cameras are essential for ensuring that the inspection system captures sufficient images to detect and count parts accurately, even at high conveyor speeds.

Understanding FPS in High-Speed Lines

Frames Per Second (FPS) refers to the number of images a camera captures per second. In high-speed production lines, where conveyors can move at speeds of several meters per second, high FPS ensures that:

- Sufficient Image Data is Captured:

High FPS cameras capture a greater number of frames as parts move quickly, reducing the risk of missed objects. - Accurate Part Detection and Counting:

Rapid frame capture ensures that small or fast-moving parts are clearly visible for detection by AI algorithms. - Blur-Free Imaging:

High FPS reduces motion blur, especially for small components or parts with intricate details.

Challenges in Counting Small Parts on High-Speed Lines

- Rapid Movement of Parts:

- As conveyors move faster, parts spend less time in the camera’s field of view. Without high FPS, fewer images are captured, increasing the likelihood of missed parts.

- Small Size and Complexity:

- Small parts often have intricate shapes, requiring detailed imaging for accurate detection and counting.

- Overlapping and Clustering:

- Overlapping parts moving at high speeds are challenging to separate without clear, high-frequency image capture.

- Motion Blur:

- At high speeds, slower FPS cameras produce blurred images, making it difficult for AI algorithms to recognize and count parts accurately.

Why High FPS Cameras Are Essential

1. Capturing More Frames for Accuracy

- High FPS cameras capture multiple frames as parts pass through the field of view, ensuring no parts are missed.

2. Reducing Motion Blur

- Higher FPS reduces exposure time, minimizing motion blur caused by rapid part movement. This is especially critical for small parts with fine details.

3. Real-Time Processing

- High FPS enables real-time imaging, allowing the AI system to process frames and provide immediate counts without slowing the production line.

4. Enhanced Part Separation

- Multiple frames provide more data for AI algorithms to distinguish overlapping or clustered parts, ensuring accurate individual counts.

Selecting the Right FPS for Your Application

1. Conveyor Speed

- The faster the conveyor moves, the higher the FPS required to ensure continuous part detection.

2. Part Size

- Smaller parts require higher resolution and FPS to capture detailed images, enabling precise detection and counting.

3. Field of View (FOV)

- The camera’s FOV must be wide enough to capture all parts on the conveyor, and high FPS ensures consistent imaging across the entire width.

4. AI Processing Capabilities

- Ensure that your AI system can handle the volume of data generated by high FPS cameras for real-time analysis.

How to Optimize High FPS Cameras for Small Part Counting

1. Pair with Proper Lighting

- Use strobing lights synchronized with the camera’s frame rate to enhance image clarity without overexposing the parts.

2. Integrate Motion Sensors

- Synchronize the camera with encoders or motion sensors to ensure frames are captured at precise intervals relative to part movement.

3. Combine with AI Algorithms

- Advanced AI models trained on high-resolution frames ensure accurate detection and counting, even in complex scenarios like overlapping parts.

4. Use Region of Interest (ROI)

- Define specific ROIs in the camera’s field of view to focus on critical areas, reducing processing time and enhancing counting efficiency.

Applications of High FPS Cameras in Small Part Counting

- Electronics Manufacturing:

- Counting tiny components like capacitors, resistors, and connectors moving rapidly on assembly lines.

- Pharmaceutical Packaging:

- Verifying the number of pills, capsules, or syringes in high-speed packaging lines.

- Food and Beverage:

- Counting small items such as candies, seeds, or nuts during packaging.

- Automotive Assembly:

- Verifying the number of bolts, washers, or other small parts in assembly kits.

- Logistics and Warehousing:

- Counting items during high-speed sorting and distribution.

Advantages of High FPS Cameras in AI-Powered Counting Systems

1. Accuracy at High Speeds

- Eliminates counting errors caused by rapid part movement.

2. Detailed Imaging

- Captures intricate details of small parts, ensuring precise detection and counting.

3. Scalability

- Handles diverse part sizes, shapes, and production speeds with minimal adjustments.

4. Real-Time Feedback

- Provides instant counts and alerts, enabling immediate corrective actions.

5. Reduced Downtime

- High FPS ensures smooth operation without requiring frequent reconfigurations or inspections.

Intelgic’s Expertise in High FPS Counting Solutions

At Intelgic, we design and implement AI-powered machine vision systems optimized for high-speed counting of small parts. Our solutions leverage high FPS cameras, advanced lighting, and robust AI algorithms to deliver unparalleled accuracy and efficiency.

Why Choose Intelgic?

- Custom Solutions:

- Systems tailored to your conveyor speed, part size, and counting requirements.

- High-Performance Cameras:

- Integration of top-tier high FPS cameras for blur-free imaging and precise counting.

- Advanced AI Models:

- Algorithms trained to handle complex counting scenarios, including overlapping parts.

- Real-Time Analytics:

- Immediate feedback on production metrics and part counts.

High FPS cameras are indispensable for accurately counting small parts on high-speed conveyors. By capturing more frames per second, they ensure precise part detection, reduce motion blur, and enable real-time analysis. Paired with AI-powered software, high FPS cameras transform traditional counting processes into efficient, scalable, and error-free operations.

Intelgic’s expertise in high-speed counting systems ensures reliable and customizable solutions for your production line. Contact Intelgic today to learn how our cutting-edge technologies can revolutionize your counting processes.