Transparent Plastic Part Inspection for Defect Detection Using Machine Vision AI

Published on: Dec 31, 2024

Written by: Content team, Intelgic

Transparent Plastic Part Inspection for Defect Detection Using Machine Vision AI

Transparent plastic parts are extensively used across industries such as automotive, medical devices, packaging, and consumer goods due to their lightweight, durability, and clarity. Ensuring the quality of these components is critical, as defects like scratches, bubbles, cracks, or contaminants can compromise their functionality and aesthetics. However, inspecting transparent plastic parts poses unique challenges, as their transparency and reflective nature can make defect detection difficult.

Machine Vision AI provides a robust solution for automating the inspection of transparent plastic parts. By leveraging advanced imaging techniques, optimized lighting, and AI-powered algorithms, manufacturers can achieve high-precision defect detection even in challenging scenarios.

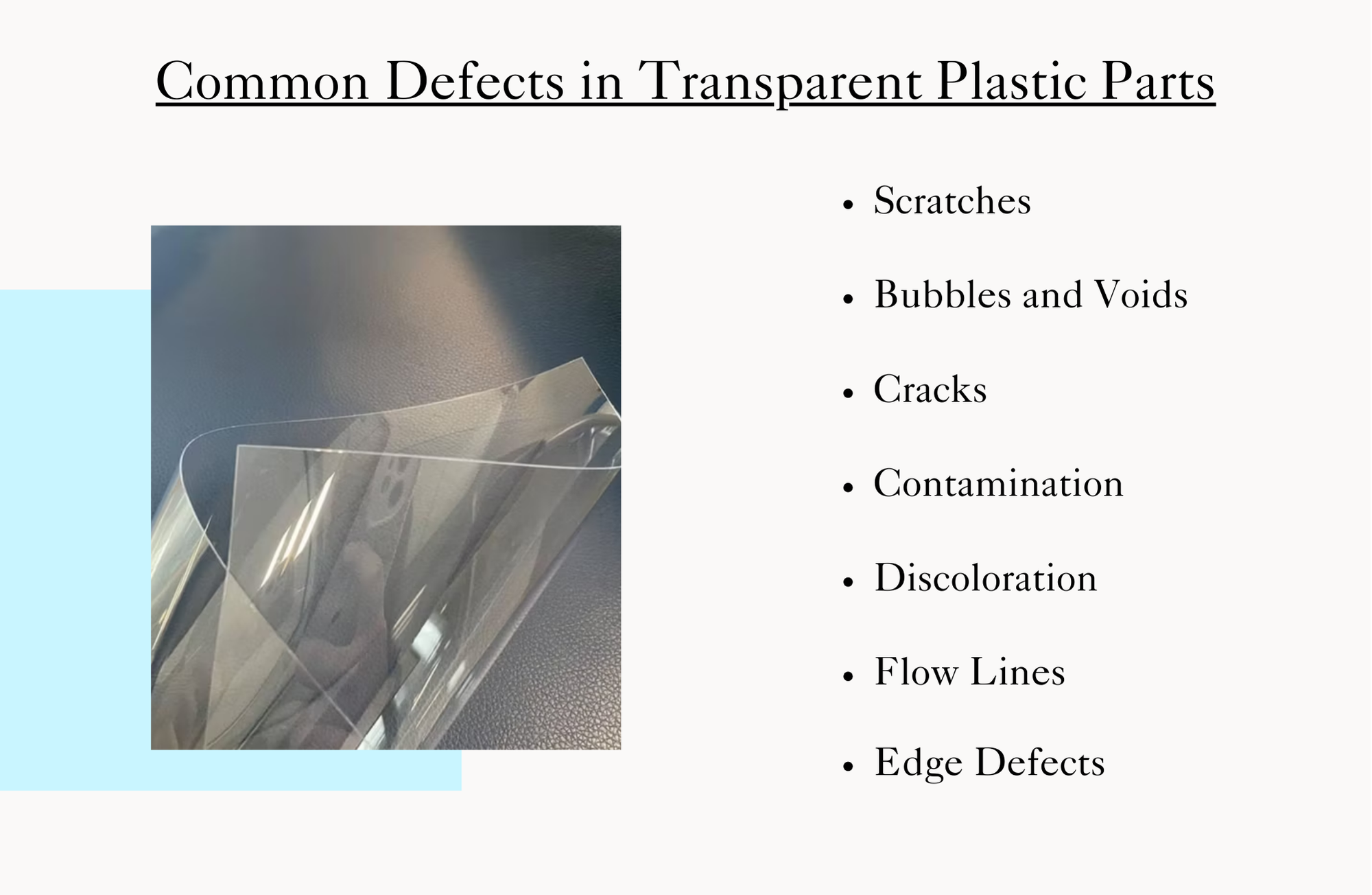

Common Defects in Transparent Plastic Parts

Transparent plastic parts are prone to various defects that can occur during molding, extrusion, or finishing processes. Common defects include:

- Scratches:

- Surface abrasions caused by handling, tooling, or processing errors.

- Bubbles and Voids:

- Air pockets trapped within the material during molding or extrusion.

- Cracks:

- Fractures or stress marks caused by material weaknesses or improper cooling.

- Contamination:

- Particles or foreign materials embedded in or adhered to the surface.

- Discoloration:

- Uneven coloring or yellowing due to improper material mixing or heat exposure.

- Flow Lines:

- Visible patterns caused by irregular material flow during molding.

- Edge Defects:

- Inconsistencies or irregularities along the edges of the part.

Challenges in Inspecting Transparent Plastic Parts

- Low Contrast:

- Defects on transparent parts are often subtle and lack contrast against the background, making them difficult to detect.

- Glare and Reflections:

- Shiny surfaces create glare and reflections that can obscure defects.

- Material Thickness Variations:

- Uneven thickness can lead to inconsistent imaging results.

- High-Speed Production:

- Transparent parts on fast-moving production lines require real-time inspection systems.

- Complex Geometries:

- Parts with intricate shapes or contours need comprehensive imaging to ensure full coverage.

How Machine Vision AI Inspects Transparent Plastic Parts

Machine Vision AI systems combine advanced cameras, lighting, and AI algorithms to overcome the challenges of inspecting transparent plastic parts.

1. High-Resolution Imaging

- Camera Selection:

- High-resolution cameras capture fine details, enabling the detection of small defects like scratches or bubbles.

- Multi-Camera Systems:

- Cameras positioned at different angles provide comprehensive coverage of complex geometries.

2. Advanced Lighting Techniques

Lighting is critical for creating contrast and highlighting defects on transparent parts.

- Backlighting:

- Light placed behind the part highlights defects such as bubbles, voids, and cracks by casting them as shadows.

- Dark Field Illumination:

- Light is directed at a shallow angle, making surface defects like scratches and contamination appear bright against a dark background.

- Polarized Lighting:

- Reduces glare and reflections, improving defect visibility on shiny surfaces.

- Diffuse Lighting:

- Provides even illumination to reduce shadows and enhance overall visibility.

3. AI-Powered Defect Detection

AI algorithms analyze images to identify and classify defects with precision.

- Pattern Recognition:

- Detects irregularities by comparing the part's surface to an ideal model.

- Contrast Enhancement:

- Adjusts image contrast to make subtle defects more visible.

- Real-Time Analysis:

- Processes images instantly, enabling immediate defect detection and corrective actions.

4. Real-Time Feedback and Sorting

- Defect Localization:

- Identifies the exact location of defects, helping operators take targeted corrective actions.

- Automated Sorting:

- Defective parts are automatically separated from acceptable ones, ensuring only high-quality products proceed.

5. Data Logging and Reporting

Inspection data is recorded for quality control and process optimization.

- Trend Analysis:

- Identifies recurring defects to address root causes.

- Production Metrics:

- Tracks quality performance over time for continuous improvement.

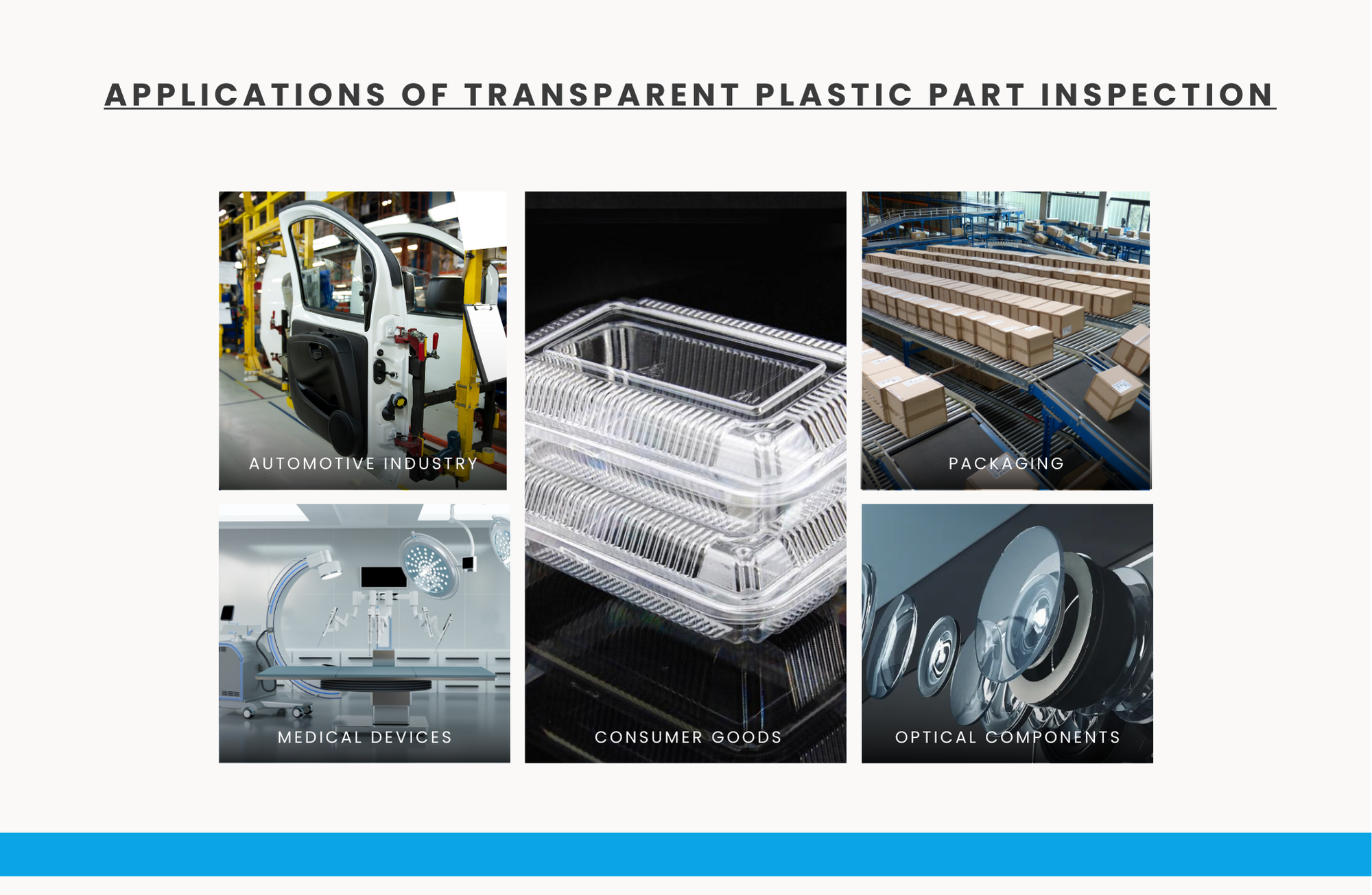

Applications of Transparent Plastic Part Inspection

1. Automotive Industry

- Inspecting clear plastic components such as headlights, taillights, and interior panels for scratches, cracks, and contamination.

2. Medical Devices

- Verifying the integrity of syringes, IV bags, and diagnostic tools for cracks, bubbles, and contamination.

3. Consumer Goods

- Ensuring defect-free transparent covers, containers, and display panels in electronics and appliances.

4. Packaging

- Inspecting transparent plastic bottles, caps, and films for contamination, bubbles, and discoloration.

5. Optical Components

- Verifying lenses, visors, and protective shields for surface defects and optical clarity.

Advantages of Using Machine Vision AI for Inspection

- High Accuracy:

- Detects even the smallest defects, ensuring consistent quality.

- Real-Time Analysis:

- Provides immediate feedback, minimizing waste and rework.

- Scalability:

- Adapts to different part sizes, shapes, and production speeds.

- Cost Efficiency:

- Reduces labor costs by automating manual inspection tasks.

- Improved Customer Satisfaction:

- Ensures defect-free products, enhancing brand reputation.

Best Practices for Transparent Plastic Part Inspection

- Optimize Lighting Setup:

- Experiment with different lighting techniques (backlighting, polarized lighting, etc.) to maximize defect visibility.

- Choose the Right Camera:

- Select high-resolution cameras with appropriate frame rates to handle production speeds.

- Calibrate the System:

- Regularly calibrate the inspection system to account for variations in part size, shape, and transparency.

- Train AI Algorithms:

- Use diverse datasets to train AI models for accurate defect detection across different parts and defects.

- Monitor and Maintain Equipment:

- Clean cameras and lighting systems regularly to maintain consistent inspection performance.

Intelgic’s Expertise in Transparent Plastic Part Inspection

At Intelgic, we specialize in designing and implementing AI-powered machine vision systems for transparent plastic part inspection. Our solutions combine high-resolution imaging, advanced lighting techniques, and robust AI algorithms to deliver unparalleled accuracy and efficiency.

Why Choose Intelgic?

- Tailored Solutions:

- Systems designed to meet the specific needs of your production line and product types.

- Advanced Technology:

- Cutting-edge cameras, lighting, and AI software for defect detection.

- Comprehensive Support:

- From consultation to implementation and maintenance, we ensure seamless integration and operation.

- Proven Results:

- Enhanced defect detection accuracy, reduced waste, and improved productivity.

Inspecting transparent plastic parts for defects is a challenging but essential task in modern manufacturing. By leveraging Machine Vision AI, manufacturers can overcome the challenges of low contrast, glare, and high production speeds, ensuring consistent quality and customer satisfaction.

Intelgic’s expertise in transparent part inspection enables manufacturers to achieve reliable, scalable, and cost-effective solutions. Contact Intelgic today to learn how our systems can revolutionize your quality control processes.