Transparent Plastic Sheet Inspection

Published on: Jan 14, 2025

Written by: Content team, Intelgic

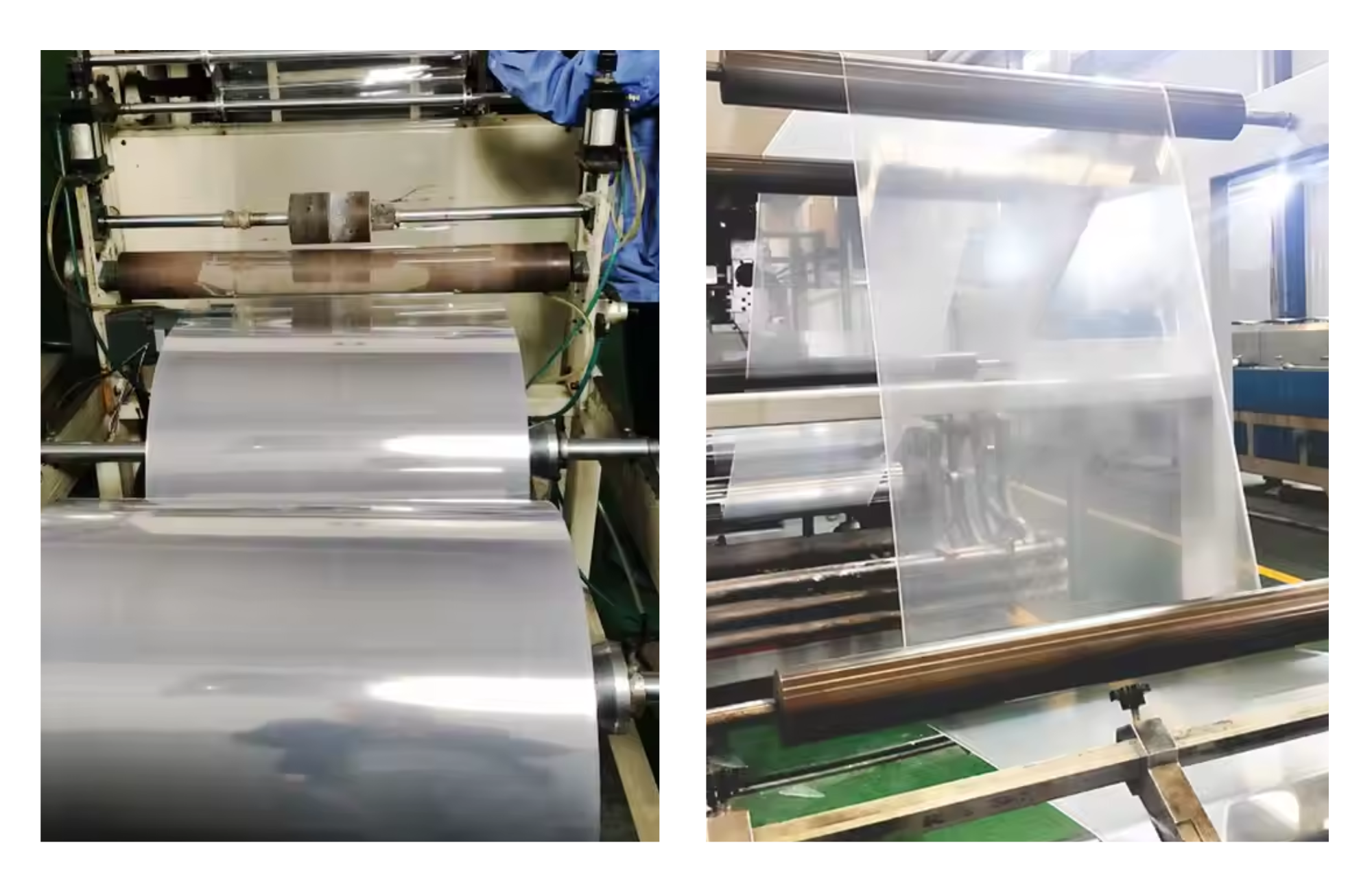

Transparent Plastic Sheet Inspection

Transparent plastic sheets are widely used in industries such as packaging, electronics, automotive, and construction. These sheets must meet stringent quality standards as even the smallest defects can compromise functionality, durability, or aesthetics. Inspecting these sheets poses unique challenges due to their size, reflectivity, and the microscopic nature of many defects. Leveraging specialized imaging techniques and AI-driven analysis provides a robust solution for ensuring consistent quality.

Challenges in Inspecting Transparent Plastic Sheets

- Wide and Large Field of View (FOV):

- Plastic sheets are often produced in widths exceeding several meters.

- Inspecting such large surfaces with uniform resolution requires high-performance imaging systems capable of covering wide areas.

- High Reflectivity:

- The reflective properties of plastic sheets cause glare and light scattering, complicating defect detection.

- Traditional lighting methods often fail to illuminate the surface evenly.

- Invisibility of Defects:

- Defects such as scratches, bubbles, or embedded particles are difficult to spot due to transparency and light diffraction.

- Microscopic Defect Sizes:

- Defect sizes can be as small as 0.1 mm or less, necessitating ultra-high-resolution imaging systems.

Common Defects in Transparent Plastic Sheets

- Surface Scratches and Scuffs:

- Caused by handling, transport, or production processes.

- Embedded Particles or Contaminants:

- Foreign particles trapped during manufacturing.

- Bubbles or Voids:

- Air pockets formed during extrusion or lamination.

- Coating Irregularities:

- Uneven application of coatings or films.

- Edge Defects:

- Frayed or damaged edges that compromise usability.

Innovative Solutions for Transparent Plastic Sheet Inspection

To overcome the challenges associated with inspecting transparent plastic sheets, advanced imaging systems and AI-powered software are employed. These solutions are tailored to meet the specific requirements of inspecting wide, reflective, and delicate materials.

1. Customized Imaging Systems

- High-Resolution Cameras:

- Employ ultra-high-resolution cameras capable of capturing minute details.

- Line scan cameras are particularly effective for inspecting large sheets continuously on production lines.

- Specialized Lenses:

- Use telecentric lenses to maintain consistent magnification and eliminate perspective distortion across the FOV.

- Autofocus lenses adapt to varying sheet thickness or uneven surfaces.

- Optimized Lighting Techniques:

- Diffuse Dome Lighting: Minimizes glare and provides uniform illumination.

- Darkfield Illumination: Highlights surface defects like scratches and particles by capturing scattered light.

- Structured Lighting: Enhances the visibility of subtle irregularities by casting patterned light across the surface.

- Wide FOV Systems:

- Combine multiple cameras or stitching algorithms to inspect large sheets seamlessly.

2. AI-Powered Defect Detection

- Real-Time Analysis:

- AI models process high-resolution images in real-time, identifying and classifying defects as sheets move through the inspection line.

- Defect Classification and Localization:

- Categorizes defects by type, size, and severity, enabling precise defect mapping.

- Anomaly Detection:

- Deep learning algorithms detect subtle and rare defects that traditional methods might overlook.

- Data Logging and Reporting:

- Logs inspection results for traceability and quality control.

- Provides actionable insights to optimize production processes.

Applications of Transparent Plastic Sheet Inspection

- Packaging Industry:

- Ensuring the clarity and durability of sheets used in food, medical, and industrial packaging.

- Electronics Manufacturing:

- Verifying the quality of films used for screens, displays, and touch panels.

- Automotive Industry:

- Inspecting sheets used in interior components, protective films, and glazing applications.

- Construction Materials:

- Ensuring defect-free sheets for architectural glazing, roofing, and protective barriers.

Advantages of Automated Inspection Systems

- Enhanced Accuracy:

- Detects microscopic defects with high precision, ensuring consistent quality.

- Improved Efficiency:

- Automates the inspection process, significantly increasing throughput.

- Objective Evaluation:

- Eliminates subjectivity associated with manual inspection.

- Scalability:

- Easily adaptable to production lines of varying speeds and sheet sizes.

- Cost Savings:

- Reduces rework, waste, and customer returns by identifying defects early.

Intelgic’s Expertise in Transparent Plastic Sheet Inspection

At Intelgic, we specialize in delivering customized solutions for inspecting transparent plastic sheets. Our offerings include:

- Tailored Imaging Systems:

- Designed to handle wide FOVs, high reflectivity, and minute defects.

- AI-Driven Software:

- Powered by advanced deep learning models to achieve unparalleled defect detection accuracy.

- End-to-End Integration:

- Seamlessly integrates with existing production lines and quality control systems.

- Ongoing Support:

- Provides training, maintenance, and upgrades to keep systems at peak performance.

Inspecting transparent plastic sheets requires overcoming unique challenges such as large FOVs, high reflectivity, and microscopic defects. By combining customized imaging solutions with AI-powered analysis, manufacturers can achieve unprecedented accuracy, efficiency, and consistency in quality assurance. Intelgic’s expertise ensures that your inspection systems deliver flawless results, protecting your brand and bottom line.

Contact us today to learn how we can enhance your inspection processes for transparent plastic sheets.