Small part inspection automation using Machine Vision AI system

Published on: Jan 06, 2025

Written by: Content team, Intelgic

Automating Inspection with Machine Vision AI

Machine Vision AI integrates advanced imaging hardware, robotics, and AI-powered analysis to automate the inspection of small parts. The system not only overcomes the limitations of manual methods but also delivers greater accuracy, speed, and scalability.

Key Components of the System

- High-Resolution Machine Vision Camera:

- Cameras with resolutions high enough to capture micron-level details.

- GigE cameras are often used due to their ability to handle large data streams and compatibility with C-mount lenses.

- Appropriate Lighting:

- Uniform and optimized lighting ensures the visibility of defects.

- Techniques such as backlighting, coaxial lighting, or ring lights may be employed depending on part characteristics.

- Powerful Lens:

- C-mount lenses are typically used to ensure high optical clarity and compatibility with the camera.

- Magnification and focus are critical for capturing fine details.

- Robotic Arm Integration:

- For parts with complex geometries, robotic arms capture multiple images from different angles.

- Ensures a comprehensive inspection of all surfaces.

- Intelgic’s Live Vision AI Software:

- Processes images to detect defects at micron levels.

- Identifies scratches, deformations, and inconsistencies with high precision.

- Capable of analyzing single-shot images or stitching multiple images for a detailed view.

Inspection Workflow

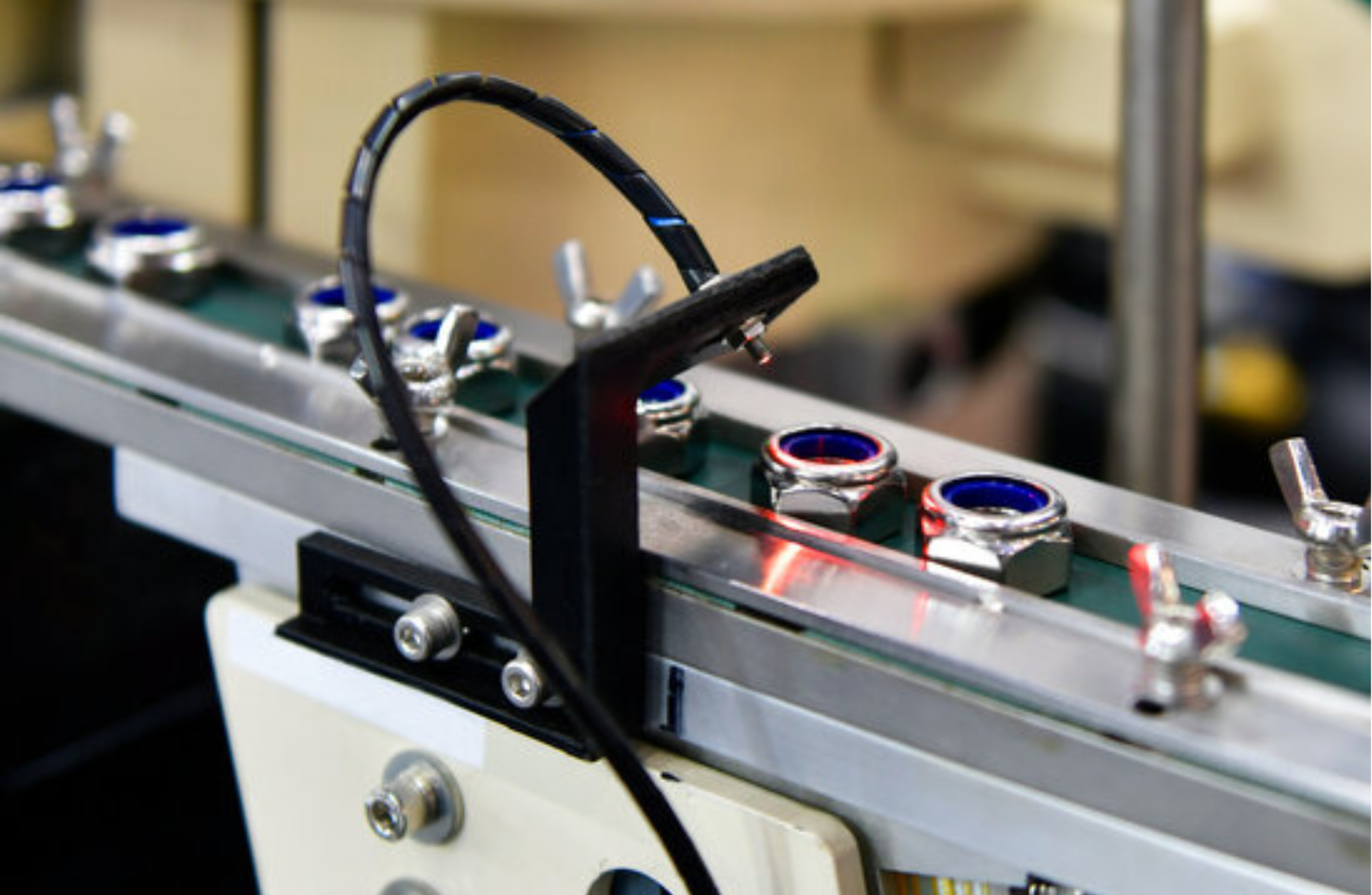

- Part Placement:

- Parts are placed on a conveyor or inspection station.

- For irregularly shaped parts, fixtures ensure proper orientation.

- Image Capture:

- Cameras capture high-resolution images under optimal lighting conditions.

- For complex parts, robotic arms position the camera to cover all surfaces.

- Image Processing:

- Intelgic’s Live Vision AI software processes the images, using advanced algorithms to detect micron-level defects.

- Techniques such as edge detection, pattern recognition, and AI-driven anomaly detection are applied.

- Defect Analysis:

- The software categorizes defects based on predefined thresholds and classifications.

- Results are visualized in an easy-to-interpret format.

- Actionable Insights:

- Automated alerts for parts that fail quality standards.

- Data is logged for traceability and process optimization.

Benefits of Automated Small Part Inspection

- Enhanced Accuracy:

- Consistent detection of defects as small as a few microns.

- Eliminates variability caused by human error.

- Improved Efficiency:

- Significantly reduces inspection time.

- Enables high-volume production without compromising quality.

- Scalability:

- Easily handles increasing production demands.

- Adaptable to new part designs with minimal reconfiguration.

- Cost Savings:

- Reduces labor costs associated with manual inspection.

- Minimizes costs related to rework and defect-related returns.

- Data-Driven Quality Assurance:

- Provides detailed defect reports and actionable insights.

- Enables continuous process improvement through analytics.

Intelgic’s Custom Machine Vision Solutions

Intelgic specializes in delivering tailored machine vision systems for complex inspection challenges. Key offerings include:

- Hardware Selection:

- Experts choose the ideal combination of camera, lens, and lighting for each application.

- Robotics Integration:

- Programming robotic arms to capture comprehensive image datasets for complex parts.

- AI-Driven Defect Detection:

- Advanced algorithms in Intelgic’s Live Vision AI software deliver unmatched accuracy and reliability.

- Customizable Solutions:

- Systems are designed to integrate seamlessly into existing workflows and meet specific inspection requirements.

Applications Beyond Small Part Inspection

The versatility of this system makes it suitable for:

- PCB inspection in electronics manufacturing.

- Detection of microcracks in medical implants.

- Inspection of precision components in aerospace engineering.

Automating the inspection of small, sensitive parts with Machine Vision AI revolutionizes quality assurance processes. By combining high-resolution imaging, robotics, and AI, industries can achieve unmatched precision and efficiency. Intelgic’s expertise in developing custom solutions ensures that even the most challenging inspection requirements are met. Investing in such systems not only enhances product quality but also drives operational excellence in today’s competitive manufacturing landscape.