Robotic Inspection System for Complex Automotive Parts Inspection

Published on: Sep 17, 2025

Written by: Content team, Intelgic

Introduction

In the modern automotive industry, precision, consistency, and speed are critical to maintaining product quality and meeting regulatory standards. As vehicles become more advanced, so do the components that go into them—many of which have intricate geometries, tight tolerances, and stringent cosmetic standards. Traditional manual inspection methods fall short in keeping up with the scale and complexity of production. This is where Robotic Inspection Systems powered by Machine Vision and AI come into play.

Intelgic’s robotic inspection systems are custom-engineered for high-precision, real-time inspection of complex automotive parts—ranging from engine components and headlamps to chassis and body parts. These systems combine advanced robotics, industrial imaging, and AI-driven defect detection to automate quality control and eliminate human error.

Why Complex Automotive Parts Need Robotic Inspection

Automotive parts are often:

-

Irregular in shape

-

Multisurfaced and multi-textured

-

Prone to cosmetic and dimensional defects post-manufacturing (painting, welding, molding, etc.)

-

Assembled with critical tolerances

Manual inspection of such parts is time-consuming, inconsistent, and often fails to detect micro-defects, misalignments, or minor deformities that could compromise safety and performance.

Intelgic’s Robotic Inspection System: Key Features

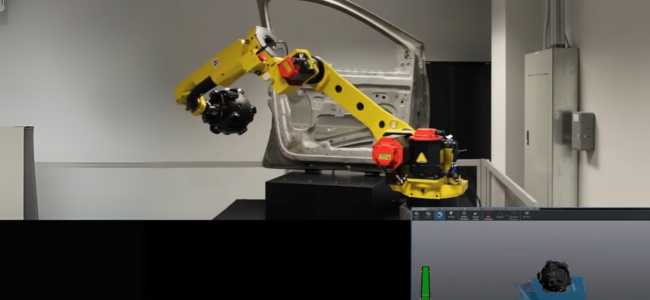

Multi-Axis Robotic Motion System

Intelgic uses 6-axis robotic arms, SCARA, or Cartesian robots to position the part or move cameras around it. This enables:

-

360° part coverage

-

Accurate camera alignment with complex contours

-

Inspection in hard-to-reach areas

High-Resolution Machine Vision Cameras

We integrate area scan cameras (20MP to 65MP) and line scan cameras (8K/16K) depending on the part geometry and required resolution.

Advanced Optics and Lighting

Specialized lenses (e.g., telecentric) and lighting configurations such as:

-

Low-angle ring lights for surface scratch detection

-

Coaxial lights for detecting cracks and dents

-

Dome and diffused lights for inspecting shiny or metallic surfaces

AI-Based Defect Detection Software

Intelgic’s proprietary Live Vision AI software is designed for real-time image processing and defect classification. It can detect:

-

Dents, scratches, pinholes

-

Welding and joining defects

-

Paint and coating issues

-

Deformation or warping

-

Missing or misaligned components

Applications in Automotive Industry

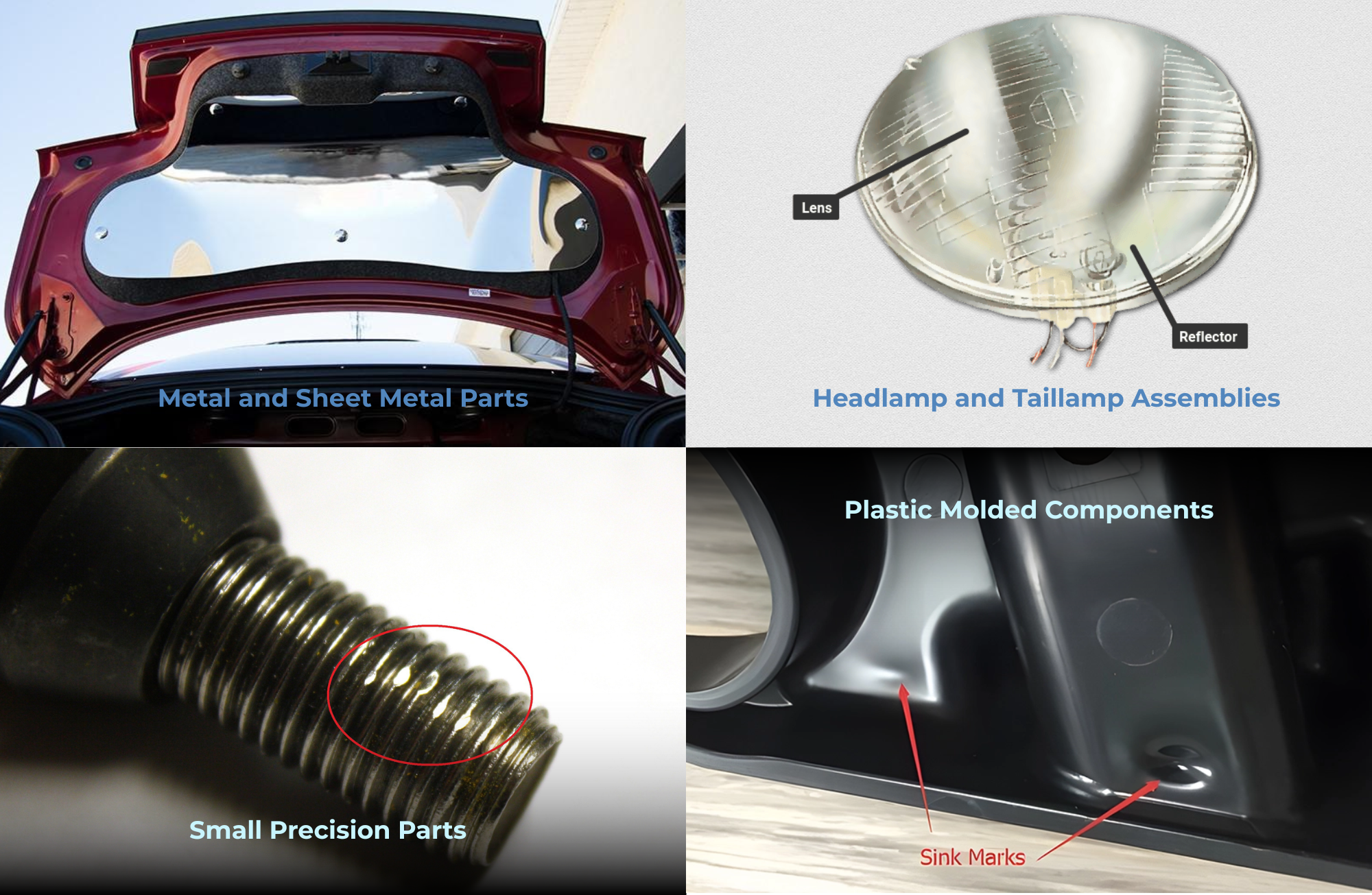

Metal and Sheet Metal Parts

Inspecting surface integrity after bending, stamping, welding, and painting:

-

Hood and trunk panels

-

Bumpers and side body frames

-

Floor pans and brackets

Headlamp and Taillamp Assemblies

-

Verifying proper fitment of reflectors, lenses, bulbs, and wiring

-

Detecting internal contamination or misalignment

-

Ensuring no cosmetic scratches or deformation

Small Precision Parts (Pins, Injectors, Fasteners)

-

Micron-level defect detection

-

Alignment verification

-

Dimensional measurements

Plastic Molded Components

-

Detecting sink marks, flash, short shots

-

Ensuring dimensional accuracy

Checking post-molding assembly

Inline Inspection for Real-Time Quality Control

Intelgic’s robotic inspection systems are designed to operate inline—integrated seamlessly into your existing assembly or production line. This enables:

-

Real-time inspection at production speed

-

Immediate feedback to PLC for stopping the line or triggering alarms

-

Reduction in scrap and rework rates

-

Continuous process improvement via inspection data

Inspection Reporting & Digital Quality Certificate (DQC)

Each part inspection is logged, and Intelgic’s software automatically generates:

-

Pass/Fail status

-

Defect locations and severity (pixel-based measurements)

-

Annotated images

-

Time-stamped inspection reports

-

A Digital Quality Certificate (DQC) for warranty validation and traceability

These reports can be uploaded to the cloud for dashboard visualization or exported via API to ERP/MES systems.

Turnkey Automation from Intelgic

Intelgic provides a complete turnkey solution that includes:

-

Robotics and motion systems (custom grippers, conveyors, actuators)

-

Vision cameras and industrial optics

-

Smart lighting and image acquisition control

-

Live Vision AI software with customizable inspection logic

-

PLC and ERP/MES integration

-

On-site or remote deployment, training, and support

Benefits of Intelgic’s Robotic Inspection System

✔ Zero-defect manufacturing with consistent inspection

✔ Minimized human intervention, increased efficiency

✔ Traceability and compliance through digital records

✔ Scalability for future upgrades and new parts

✔ Faster ROI by reducing scrap, rework, and recalls

As the complexity of automotive components continues to rise, relying on manual inspection or basic vision systems is no longer viable. Intelgic’s Robotic Inspection System offers a smart, scalable, and reliable solution for high-speed, high-precision inspection across a wide variety of automotive parts.

If your production demands zero defects and continuous quality assurance, partner with Intelgic to automate your inspection processes today.