Part Identification and Recognition Using Machine Vision AI

Published on: Jan 23, 2025

Written by: Content team, Intelgic

Part Identification and Recognition Using Machine Vision AI

In modern manufacturing, accurate part identification and recognition are critical for ensuring process efficiency, quality control, and traceability. This involves detecting, identifying, and verifying components as they move through various stages of production. Machine Vision AI has emerged as a powerful tool to automate and enhance part identification and recognition processes, providing real-time insights and minimizing human error.

This article explores the fundamentals of part identification and recognition using Machine Vision AI, the challenges involved, and how advanced technologies address these challenges.

Identification Parts in Real Time

Part identification and recognition refers to the process of identifying individual components based on their physical characteristics, labels, or codes (e.g., barcodes or QR codes). This process is essential for:

- Verifying the correct part is being used at each stage of production.

- Labeling the parts

- Sorting and categorizing parts for further processing or packaging.

- Tracking parts for traceability and compliance.

- Ensuring seamless assembly in complex manufacturing processes.

Applications of Part Identification and Recognition

- Automotive Industry:

- Identifying engine components, body panels, and fasteners for assembly.

- Doors, Panels other similar Industries:

- Large components such as door panels, wooden panels etc. can be identified and labelled using AI. It captures various features such as the number of holes, their positions and other features to recognize the part number.

- Aerospace Industry:

- Tracking parts used in aircraft assembly to ensure compliance with safety standards.

- Consumer Goods:

- Identifying and categorizing components for packaging and labeling.

Challenges in Part Identification and Recognition

- High Variability:

- Parts may vary in size, shape, color, and material, requiring adaptable recognition systems.

- Poor Visibility:

- Labels, markings, or codes may be obscured, damaged, or misaligned.

- High-Speed Production:

- Parts moving rapidly on conveyors require real-time recognition capabilities.

- Complex Geometries:

- Irregular shapes or intricate designs can make parts difficult to recognize.

- Lighting and Environmental Factors:

- Glare, shadows, or varying light conditions can interfere with imaging.

- Multiple Similar Parts:

- Distinguishing between parts with subtle differences requires high precision.

How Machine Vision AI Enhances Part Identification and Recognition

1. High-Resolution Imaging

We need high resolution cameras for detailed imaging. We need to choose the camera carefully based on the part size, working distance, features that need to be extracted, hole size etc. Depending on the inspection area or line, we need to choose the image sensor- either line scan or area scan imaging device.

2. Advanced Lighting Solutions

Proper lighting ensures consistent imaging and highlights key features of parts.

- Diffuse Lighting:

- Reduces glare and ensures even illumination for reflective or shiny parts.

- Directional Lighting:

- Enhances edge details and surface features.

- Backlighting:

- To identify holes, threading and other critical features, backlighting is used.

- Multi-Angle Illumination:

- Ensures comprehensive coverage of irregularly shaped parts. Also these eliminates shadow that may cause confusion.

3. AI-Powered Image Analysis

AI algorithms analyze captured images to identify and classify parts with high accuracy.

- Feature Extraction:

- AI detects key characteristics such as edges, textures, and markings, holes etc.

- Pattern Recognition:

- Identifies parts by matching their features to predefined templates or databases.

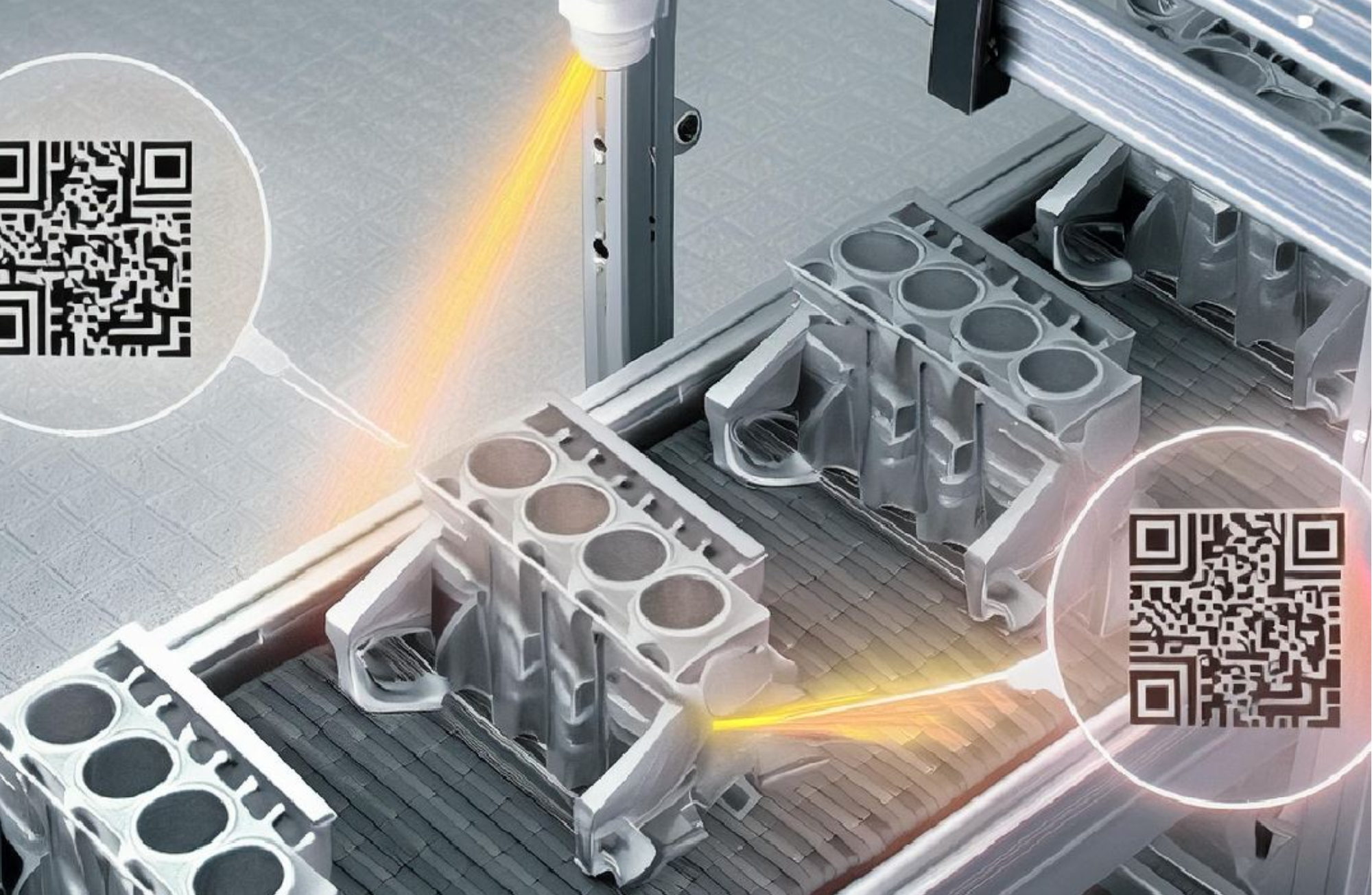

- Optical Character Recognition (OCR):

- Reads alphanumeric text, barcodes, or QR codes on parts for verification and tracking.

- Real-Time Processing:

- Processes images instantly, enabling immediate identification and decision-making.

4. Integration with Production Systems

- Sensors and Triggers:

- Synchronize image capture with part movement to ensure precise identification.

- Data Logging and Reporting:

- Records part data for traceability, compliance, and quality control.

- Automated Sorting:

- Directs parts to the correct processing lines based on recognition results.

How Part Identification Works

- Imaging:

Cameras capture high-resolution images of parts on a conveyor or inspection platform. - Lighting Optimization:

Lighting is adjusted to enhance visibility and highlight critical features. - AI Analysis:

The AI model processes images to identify parts, read labels, and detect features. - Decision Making:

The system determines whether the part matches predefined specifications or classifications. - Feedback and Sorting:

Identified parts are directed to the appropriate process or flagged for further inspection.

Applications of Machine Vision AI in Part Identification

1. Barcode and Label Recognition

- Reads barcodes, QR codes, or data matrix codes for part identification and tracking.

2. Shape and Size Verification

- Ensures parts conform to specified dimensions and shapes.

3. Defect Detection

- Identifies defects such as scratches, misalignments, or missing features during recognition.

4. Assembly Verification

- Verifies that the correct parts are being used in the assembly process.

5. Sorting and Categorization

- Automatically categorizes parts based on their features for further processing or packaging.

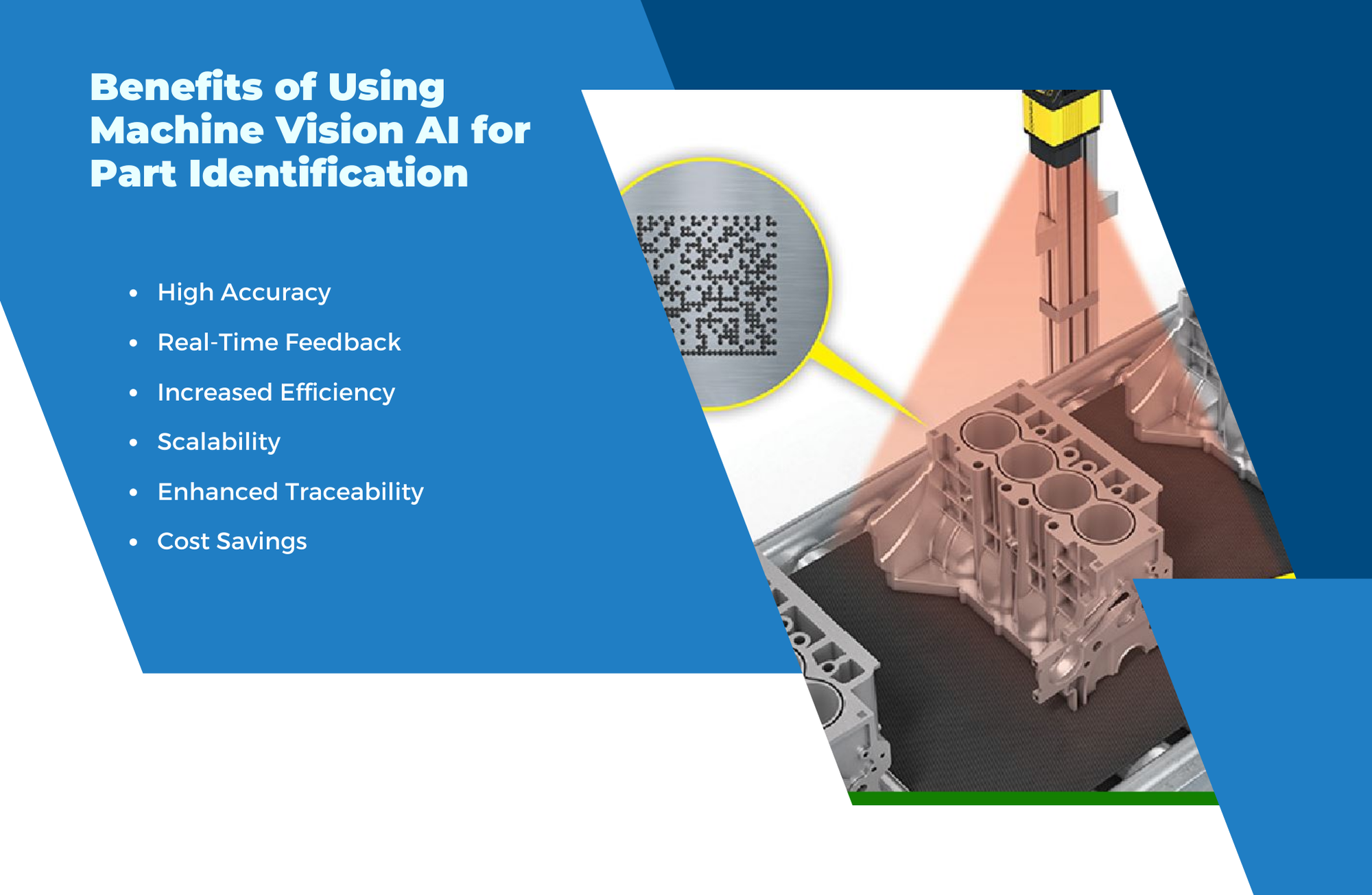

Benefits of Using Machine Vision AI for Part Identification

- High Accuracy:

- Ensures precise identification, even for small or complex parts.

- Real-Time Feedback:

- Provides immediate insights for faster decision-making and process adjustments.

- Increased Efficiency:

- Automates repetitive tasks, reducing manual labor and speeding up production.

- Scalability:

- Adapts to various part types, sizes, and production speeds.

- Enhanced Traceability:

- Tracks parts throughout the production process for quality control and compliance.

- Cost Savings:

- Reduces errors, waste, and rework, lowering overall production costs.

Best Practices for Implementing Part Identification Systems

- Select the Right Camera and Lighting:

- Choose cameras and lighting setups that suit the parts' material, size, and speed.

- Train AI Models:

- Use diverse datasets to train AI algorithms for robust recognition across varying conditions.

- Calibrate Regularly:

- Ensure cameras, lighting, and sensors are properly calibrated for consistent performance.

- Monitor System Performance:

- Continuously evaluate the system's accuracy and adjust settings as needed.

- Integrate Seamlessly:

- Ensure the system integrates with existing production lines and software for smooth operation.

Intelgic’s Expertise in Part Identification and Recognition

At Intelgic, we specialize in designing and deploying AI-powered machine vision systems for part identification and recognition. Our solutions combine cutting-edge imaging technologies, advanced AI algorithms, and seamless integration to deliver reliable and scalable systems tailored to your production needs.

Why Choose Intelgic?

- Customizable Solutions:

- Systems designed to handle your specific part types and production requirements.

- Advanced AI Models:

- Robust algorithms trained for high accuracy in diverse scenarios.

- Real-Time Analytics:

- Provides actionable insights and enhances decision-making.

- Comprehensive Support:

- From design and implementation to maintenance, we ensure seamless operation.

Part identification and recognition are essential for ensuring efficiency, quality, and traceability in modern manufacturing. Machine Vision AI systems automate this process, overcoming challenges such as part variability, high-speed production, and complex geometries. By leveraging advanced imaging, optimized lighting, and AI-powered analysis, manufacturers can achieve precise and efficient part identification, reducing errors and improving productivity.

Intelgic’s expertise in machine vision systems ensures reliable and scalable solutions for your identification and recognition needs. Contact Intelgic today to learn how we can revolutionize your quality control and production processes.