Industrial Lenses for Machine Vision and Inspection Automation

Published on: Jan 09, 2025

Written by: Content team, Intelgic

Understanding Industrial Lenses for Machine Vision and Inspection Automation Applications

Industrial lenses play a pivotal role in machine vision and inspection automation, determining the quality, accuracy, and efficiency of imaging systems. Selecting the right lens is crucial for achieving optimal performance in applications ranging from quality assurance to defect detection. This article delves into the various types of industrial lenses, their features, applications, and factors to consider when selecting a lens for your machine vision system.

Why Are Industrial Lenses Important?

Industrial lenses are the optical components responsible for capturing and projecting images onto the camera sensor. The quality and type of lens directly impact:

- Resolution: Clarity and detail of the captured image.

- Field of View (FOV): The area visible through the lens.

- Depth of Field (DOF): The range of distance within which objects remain in focus.

- Distortion: The accuracy of the image representation.

- Light Sensitivity: The amount of light reaching the sensor for proper imaging.

In machine vision systems, where precision is paramount, lenses must be carefully selected to match the application’s requirements.

Types of Industrial Lenses

1. Fixed Focal Length Lenses

- Features:

- Offer a single focal length, providing consistent magnification and perspective.

- High resolution and minimal distortion.

- Applications:

- Suitable for applications requiring fixed working distances, such as defect detection, assembly line inspections or barcode reading.

2. Varifocal Lenses

- Features:

- Adjustable focal length within a range.

- Greater flexibility but lower precision compared to fixed focal lenses.

- Applications:

- Ideal for setups requiring adjustable FOV, such as surveillance or preliminary inspections.

3. Telecentric Lenses

- Features:

- Maintain consistent magnification regardless of the object’s distance from the lens.

- Eliminate perspective distortion, ensuring accurate measurements.

- Applications:

- Used for precision measurements, such as gauging, metrology, and component alignment.

4. Autofocus Lenses

- Features:

- Automatically adjust focus based on object distance.

- Provide real-time adaptability for dynamic environments.

- Applications:

- Useful for robotic inspection systems and applications with varying object distances.

5. Line Scan Lenses

- Features:

- Designed for line scan cameras, capturing high-resolution images of moving objects.

- Provide high accuracy for long, continuous surfaces.

- Applications:

- Common in applications like surface inspection of sheets, textiles, or metal.

Key Specifications of Industrial Lenses

- Focal Length:

- Determines the lens’s magnification and FOV. Shorter focal lengths offer wider FOV, while longer focal lengths provide higher magnification.

- Aperture (f-number):

- Controls the amount of light entering the lens. Lower f-numbers allow more light, beneficial for low-light environments.

- Working Distance:

- The distance between the lens and the object being inspected. Must align with system design.

- Image Format:

- Should match the camera’s sensor size to avoid vignetting or reduced resolution.

- Resolution:

- The ability to distinguish fine details, typically measured in line pairs per millimeter (lp/mm).

- Distortion:

- Minimal distortion is critical for applications requiring accurate measurements.

Factors to Consider When Choosing an Industrial Lens

- Application Requirements:

- Define the inspection task, such as defect detection, measurement, or surface inspection.

- Object Size and Distance:

- Determine the FOV and working distance to select an appropriate focal length and lens type.

- Lighting Conditions:

- Ensure the lens can handle the lighting setup, whether it’s backlighting, coaxial lighting, or ring lighting.

- Camera Specifications:

- Match the lens’s image format and resolution to the camera sensor.

- Environmental Factors:

- Consider robustness against vibrations, temperature fluctuations, and contamination.

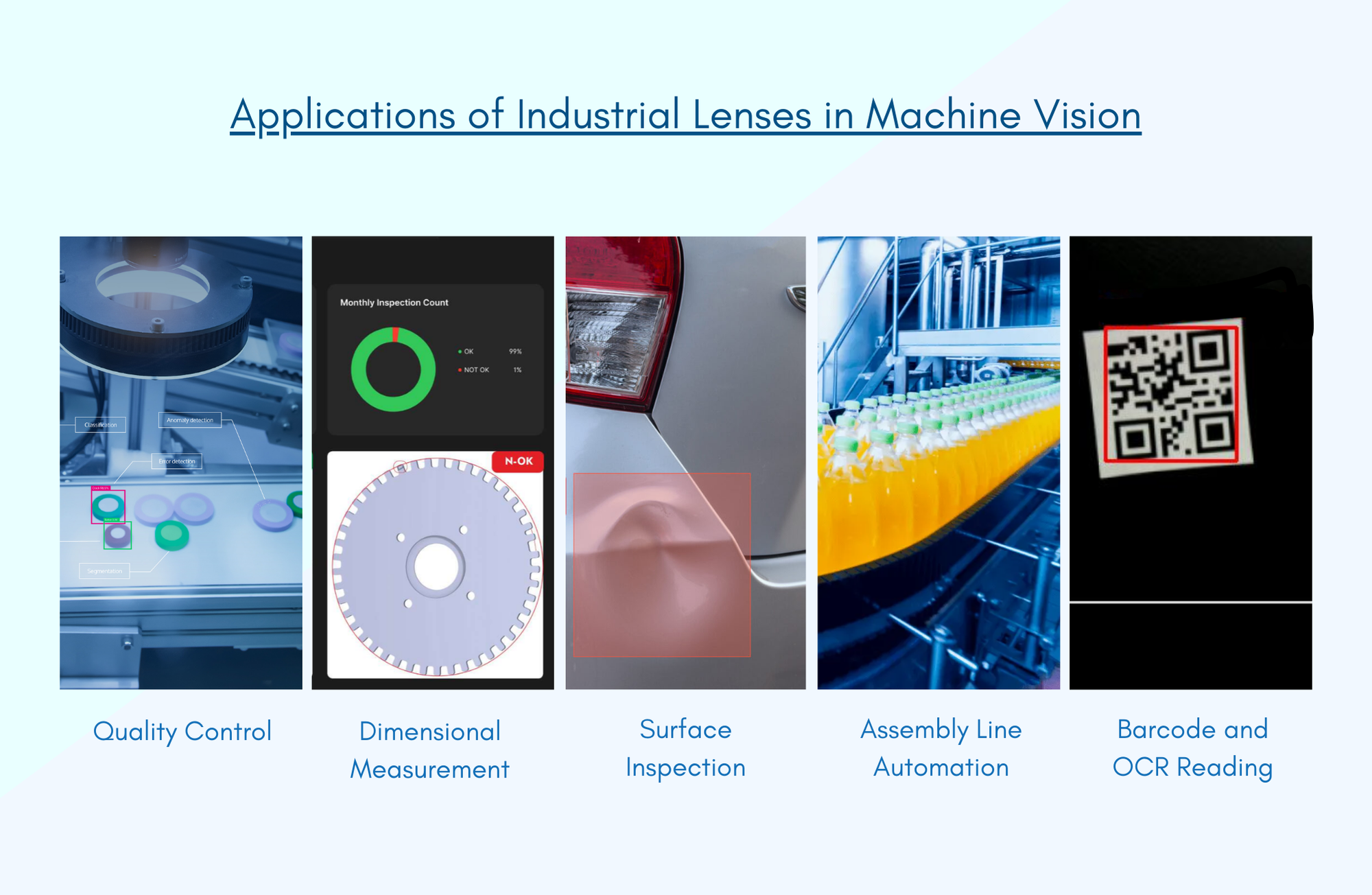

Applications of Industrial Lenses in Machine Vision

- Quality Control:

- Inspecting products for defects, such as scratches, cracks, or misalignments.

- Dimensional Measurement:

- Gauging sizes, shapes, and distances with telecentric lenses.

- Surface Inspection:

- Detecting irregularities on surfaces like glass, metals, or plastics.

- Assembly Line Automation:

- Ensuring proper placement and assembly of components.

- Barcode and OCR Reading:

- Reading codes and text with precision in logistics and manufacturing.

Intelgic’s Expertise in Lens Selection

At Intelgic, we understand that the success of a machine vision system hinges on selecting the right lens. Our experts evaluate:

- Target object and defect size.

- Working environment and lighting conditions.

- Camera compatibility and application goals.

By leveraging our expertise, we ensure that every component in your system works in harmony, delivering exceptional results.

Industrial lenses are the cornerstone of any machine vision or inspection automation application. The right lens not only enhances image quality but also ensures accurate and reliable results. By understanding your specific requirements and leveraging the latest advancements in optical technology, Intelgic helps you build robust and efficient inspection systems.

Contact us today to learn more about our industrial lens solutions and how we can optimize your inspection processes.