Hoist Cable Inspection Automation using Machine Vision AI

Published on: Dec 17, 2024

Written by: Soumen das

Hoist Cable Inspection: Ensuring Safety and Reliability with Advanced Technology

Hoist cables are critical components in industries such as construction, mining, shipping, and manufacturing, where they are used to lift, support, and move heavy loads. Their performance and integrity directly impact safety and operational efficiency. Over time, hoist cables are exposed to various stressors, including heavy loads, environmental conditions, and wear, leading to potential defects like broken strands, corrosion, or abrasion.

Regular and accurate hoist cable inspection is essential to prevent failures, ensure safety, and maintain optimal operational performance. With the advent of Machine Vision AI and Automated Optical Inspection (AOI) systems, hoist cable inspection has become more reliable, efficient, and precise. This article explores the importance of hoist cable inspection, common defects, inspection challenges, and how advanced technologies are transforming the process.

The Importance of Hoist Cable Inspection

Hoist cables are often subjected to extreme stress and operate in challenging environments. Without proper inspection and maintenance, cable failures can lead to catastrophic consequences, including accidents, equipment damage, and costly downtime.

Key Reasons for Regular Hoist Cable Inspection

-

Safety Assurance:

-

Prevents accidents caused by sudden cable failures.

-

Protects workers and equipment in high-risk operations.

-

-

Operational Efficiency:

-

Reduces unplanned downtime by identifying potential issues early.

-

Ensures continuous and smooth operation.

-

-

Cost Savings:

-

Prevents costly repairs and replacements by addressing minor defects early.

-

Reduces liability risks associated with accidents or failures.

-

-

Regulatory Compliance:

-

Meets industry safety standards and legal requirements for equipment maintenance and inspection.

-

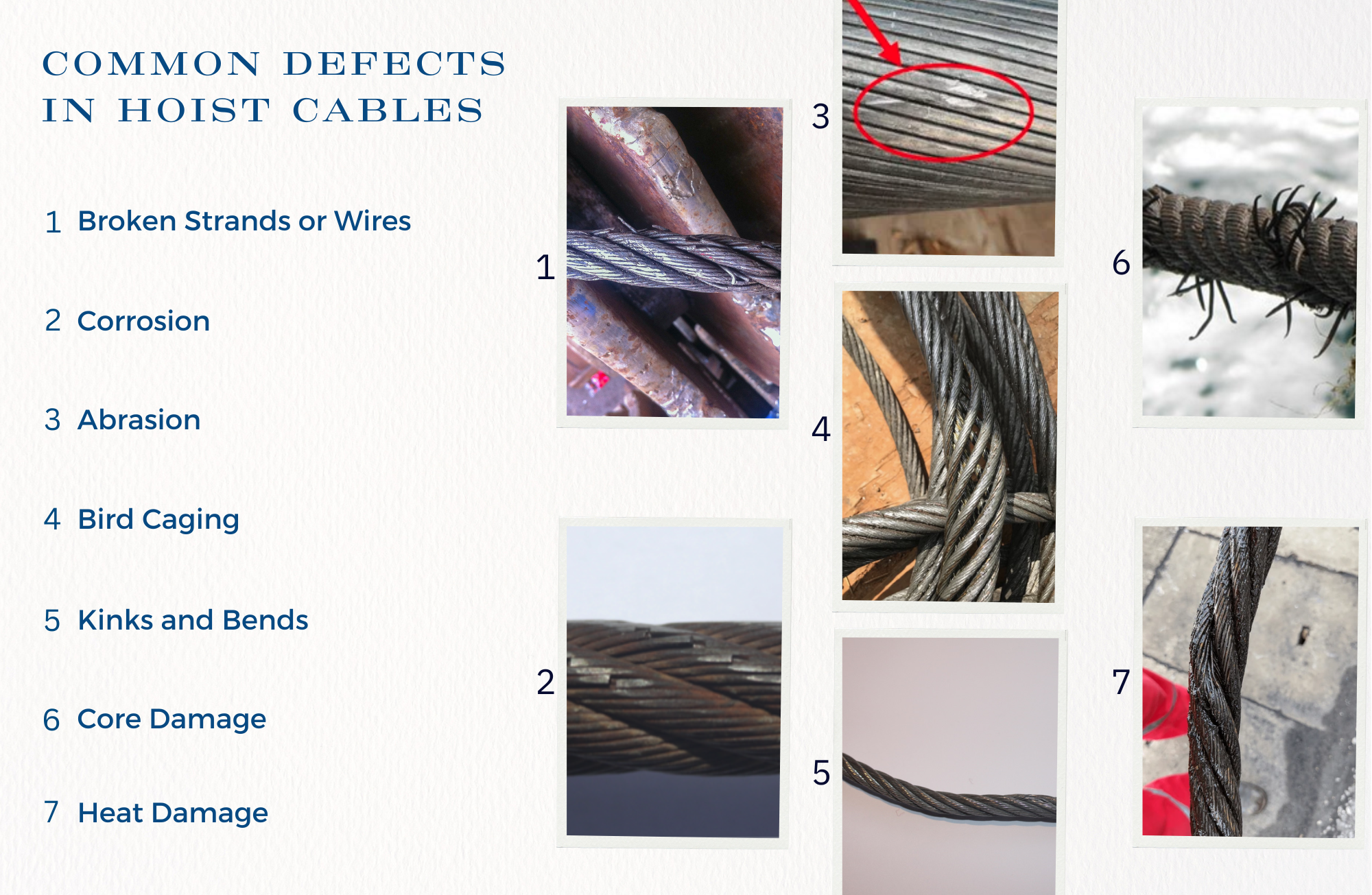

Common Defects in Hoist Cables

1. Broken Strands or Wires:

-

Occurs due to overloading, fatigue, or bending stress.

-

Reduces the cable’s load-bearing capacity.

2. Corrosion:

-

Caused by exposure to moisture, chemicals, or harsh environments.

-

Weakens the cable structure and accelerates wear.

3. Abrasion:

-

Friction with other components or surfaces leads to wear and thinning of wires.

4. Bird Caging:

-

Deformation of strands caused by excessive twisting or sudden load release.

5. Kinks and Bends:

-

Permanent deformations that compromise cable flexibility and strength.

6. Core Damage:

-

Popped or shifted cores affecting the balance and load distribution.

7. Heat Damage:

-

Discoloration or weakening caused by exposure to high temperatures.

Challenges in Hoist Cable Inspection

Inspecting hoist cables manually or with traditional methods presents several challenges:

-

Length and Accessibility:

-

Hoist cables are often long and used in inaccessible locations, making thorough inspection difficult.

-

-

Small Defects:

-

Microscopic cracks or wire breaks are difficult to detect with the naked eye.

-

-

Dynamic Conditions:

-

Cables in motion, such as during lifting operations, complicate inspection.

-

-

Surface Complexity:

-

Strands and grooves require high-resolution imaging for detailed analysis.

-

-

Time and Labor Intensive:

-

Manual inspections are slow, inconsistent, and prone to human error.

-

Advanced Technology in Hoist Cable Inspection

1. Machine Vision AI for Automated Inspection

Machine Vision AI systems use high-resolution cameras, advanced lighting, and AI-powered algorithms to automate the inspection process. These systems address the limitations of traditional inspection methods and deliver superior results.

-

Real-Time Defect Detection:

Captures and analyzes images in real-time, identifying defects instantly. -

Micron-Level Precision:

Detects small defects, such as broken wires or cracks, that are invisible to the naked eye. -

Defect Classification:

AI categorizes defects by type, size, and severity, enabling targeted maintenance.

2. Multi-Camera Systems for 360-Degree Imaging

To inspect all sides of the cable, multiple cameras are used to provide complete coverage.

-

Comprehensive Imaging:

Captures the entire surface of the cable, including grooves and strands. -

Synchronized Operation:

Ensures consistent imaging even for moving cables.

3. Advanced Lighting Solutions

Proper lighting is essential for capturing clear and detailed images of the cable surface.

-

Directional Lighting:

Enhances visibility of surface defects like scratches and cracks. -

Diffuse Lighting:

Reduces glare and highlights defects on reflective surfaces.

4. Vibration Control Mechanisms

For cables in motion or under tension, vibration can interfere with imaging.

-

Stabilization Systems:

Rollers or guides reduce cable movement, ensuring clear and stable images. -

Optimal Inspection Points:

Identifying low-vibration zones for inspection enhances accuracy.

5. Data Analytics and Reporting

Inspection systems provide detailed reports and analytics, offering valuable insights into cable health.

-

Defect Mapping:

Pinpoints exact locations of defects for targeted repairs. -

Trend Analysis:

Tracks defect progression over time, enabling predictive maintenance.

Benefits of Advanced Hoist Cable Inspection Systems

-

Enhanced Safety:

-

Identifies defects early, preventing potential failures and accidents.

-

-

Increased Accuracy:

-

Detects even the smallest defects with high precision.

-

-

Efficiency and Speed:

-

Automates the inspection process, reducing downtime and labor costs.

-

-

Consistency and Reliability:

-

Eliminates human error and provides repeatable, objective results.

-

-

Comprehensive Insights:

-

Generates actionable data for proactive maintenance planning.

-

Intelgic’s Custom Hoist Cable Inspection Solutions

At Intelgic, we specialize in designing and implementing custom inspection systems tailored to the unique challenges of hoist cables. Our solutions combine Machine Vision AI, multi-camera systems, and advanced lighting to deliver unparalleled inspection accuracy and reliability.

Key Features of Intelgic’s Systems

-

High-Resolution Imaging:

Captures fine details of cable surfaces for precise defect detection. -

AI-Powered Analysis:

Identifies and classifies defects in real-time, ensuring quick feedback and action. -

Custom Electromechanical Systems:

Includes stabilizers and rollers to control cable movement during inspection. -

Seamless Integration:

Easily integrates with existing hoist systems for minimal disruption. -

Scalability:

Suitable for various cable lengths, diameters, and operational conditions.

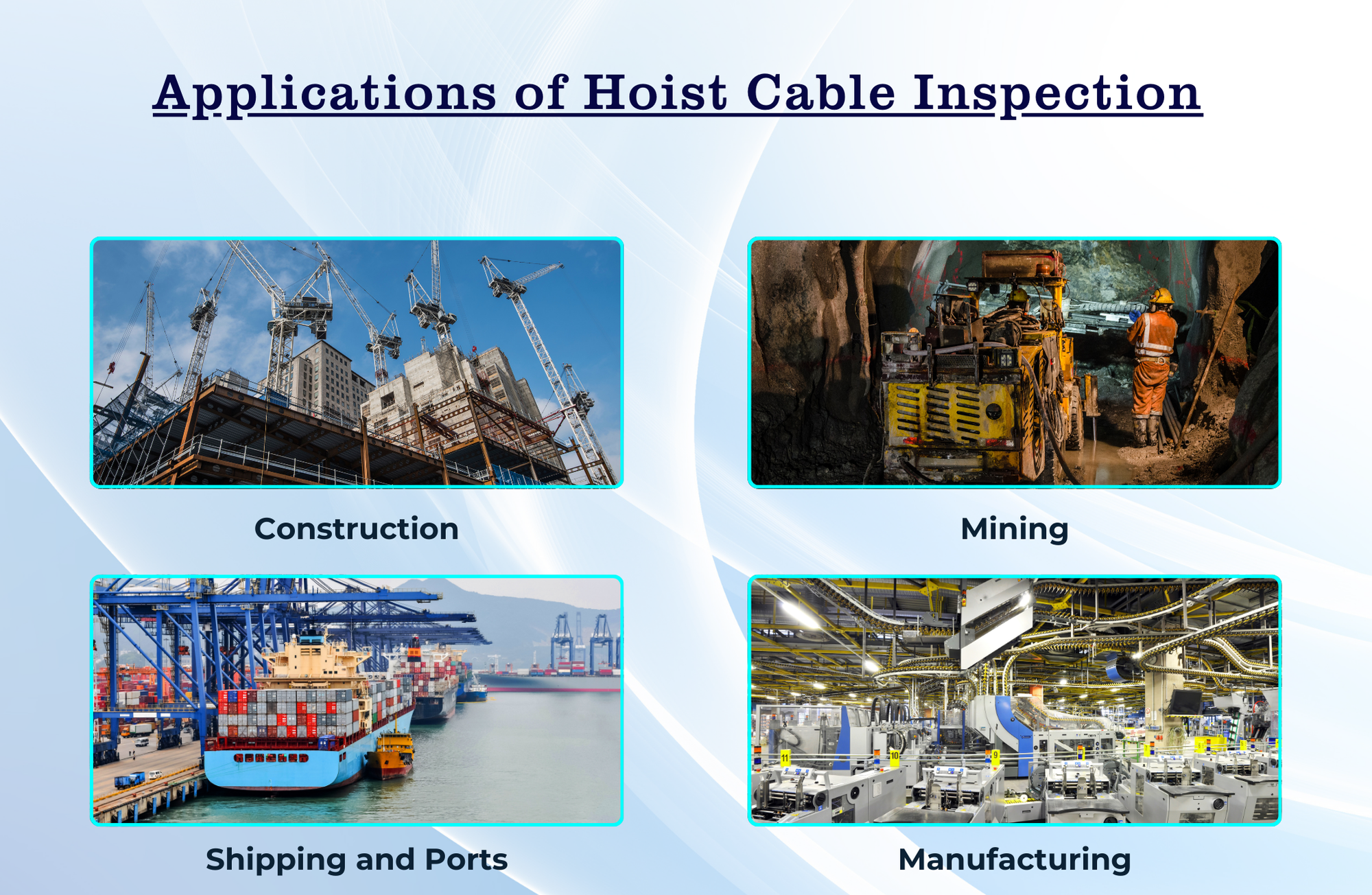

Applications of Hoist Cable Inspection

-

Construction:

Inspecting cranes, hoists, and lifting equipment. -

Mining:

Ensuring the integrity of cables in winches and haulage systems. -

Shipping and Ports:

Monitoring cables used in cargo handling and mooring. -

Manufacturing:

Inspecting overhead cranes and material handling systems.

Hoist cable inspection is a critical process that ensures safety, reliability, and operational efficiency in industries where cables are used to lift and move heavy loads. Traditional inspection methods often fall short due to the size, complexity, and dynamic nature of hoist cables. Advanced technologies like Machine Vision AI and Automated Optical Inspection (AOI) systems offer a transformative solution, enabling manufacturers and operators to detect defects with micron-level precision, improve safety, and reduce costs.

Intelgic’s custom hoist cable inspection solutions combine cutting-edge imaging, AI-powered analysis, and stabilization systems to deliver comprehensive and reliable inspections. Contact Intelgic today to learn how our innovative systems can enhance the safety and efficiency of your operations.