Capture Tribal Knowledge and Improve Production Accuracy Using Machine Vision AI and AOI Systems

Published on: Dec 12, 2024

Written by: Soumen das

Capture Tribal Knowledge and Improve Production Accuracy Using Machine Vision AI and AOI Systems

In manufacturing, tribal knowledge refers to the expertise, insights, and unwritten practices accumulated by experienced workers over time. While invaluable, this knowledge often resides solely in the minds of seasoned employees, making it difficult to scale, standardize, or preserve when those individuals leave the organization.

By leveraging Machine Vision AI and Automated Optical Inspection (AOI) systems, manufacturers can capture and codify this tribal knowledge into automated processes. These systems ensure consistent production quality, reduce reliance on individual expertise, and enhance accuracy across operations. This article explores how Machine Vision AI and AOI systems transform tribal knowledge into actionable intelligence, improving production efficiency and accuracy.

What is Tribal Knowledge?

Tribal knowledge encompasses informal insights, techniques, and problem-solving strategies developed by workers on the factory floor. While it is often essential for resolving issues, it presents several challenges:

- Lack of Documentation:

Tribal knowledge is rarely documented, making it inaccessible to new employees or scalable across teams. - Dependence on Individuals:

If experienced workers leave, their knowledge leaves with them, creating skill gaps and inefficiencies. - Inconsistency:

Human decision-making can vary, leading to irregularities in quality control and production processes.

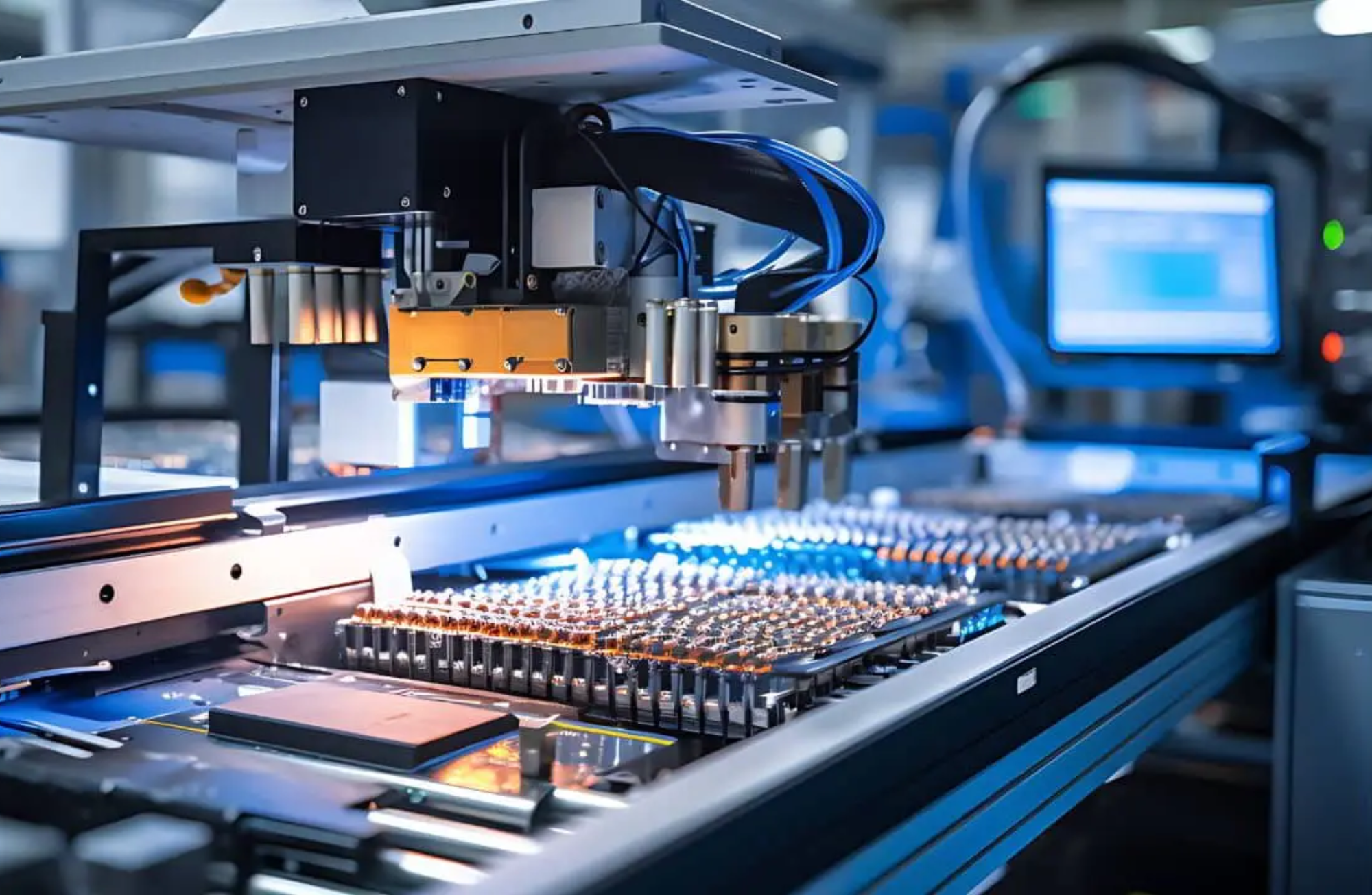

The Role of Machine Vision AI and AOI Systems

Machine Vision AI and AOI systems bridge the gap between tribal knowledge and standardized manufacturing processes. These systems use advanced imaging, artificial intelligence, and automation to replicate and improve upon human expertise, ensuring consistent and accurate production.

1. Capturing Tribal Knowledge

Machine Vision AI systems are trained using data generated by experienced workers during manual inspections and operations. Over time, these systems learn to replicate the decision-making processes of experts.

- Data Collection:

Cameras and sensors capture real-world inspection scenarios, recording defect types, corrective actions, and quality benchmarks. - AI Training:

Machine learning algorithms analyze the data, identifying patterns and decision-making criteria used by skilled workers. - Knowledge Codification:

The AI system codifies this tribal knowledge into repeatable, automated processes.

2. Improving Production Accuracy

Once trained, Machine Vision AI and AOI systems deliver highly accurate and consistent results, eliminating human error and variability.

- Defect Detection:

These systems identify even the smallest defects with precision, ensuring high-quality products. - Real-Time Feedback:

AOI systems provide instant feedback, enabling quick corrective actions and minimizing production delays. - Scalability:

Unlike human expertise, AI-driven systems can scale to multiple production lines, ensuring uniformity across facilities.

Advantages of Using Machine Vision AI and AOI Systems

1. Standardization Across Processes

By capturing tribal knowledge and converting it into automated systems, manufacturers achieve consistent quality and operational standards across teams and locations.

2. Increased Efficiency

Automating inspection and production tasks reduces reliance on manual labor, increases throughput, and eliminates bottlenecks caused by skill shortages.

3. Enhanced Accuracy

Machine Vision AI systems detect defects and anomalies at a micron level, far exceeding human capabilities, and ensuring the highest level of precision.

4. Knowledge Retention

Even when experienced workers leave, their expertise remains embedded in the AI system, preserving institutional knowledge and reducing skill gaps.

5. Real-Time Insights

AOI systems generate detailed reports and analytics, providing actionable insights into production trends, defect patterns, and process inefficiencies.

6. Reduced Costs

By minimizing rework, waste, and downtime, manufacturers can significantly reduce production costs while improving product quality.

Applications of Machine Vision AI and AOI Systems in Manufacturing

1. Quality Inspection

- Detecting surface defects, dimensional inaccuracies, and assembly errors in automotive, electronics, and medical devices.

2. Process Automation

- Automating repetitive tasks such as labeling, sorting, and part alignment.

3. Predictive Maintenance

- Monitoring equipment and components to predict and prevent failures before they occur.

4. Complex Product Inspection

- Handling diverse shapes, sizes, and materials in products such as wires, tubes, and intricate assemblies.

5. Training New Employees

- Using AI-powered insights to train new workers, replicating the decision-making process of experienced employees.

How Intelgic Captures Tribal Knowledge with Machine Vision AI

Intelgic specializes in designing and implementing custom Machine Vision AI and AOI systems that transform tribal knowledge into automated solutions. Here’s how Intelgic’s approach ensures success:

1. Data-Driven AI Training

- Intelgic works closely with manufacturers to gather data on defect detection, production processes, and quality benchmarks.

- AI algorithms are tailored to replicate the specific expertise of experienced workers.

2. Customized AOI Systems

- Intelgic designs AOI systems with high-resolution imaging, advanced lighting, and precision motion control to handle diverse inspection needs.

3. Scalable Integration

- Intelgic’s systems are designed to integrate seamlessly into existing production lines, enabling easy scalability and minimal disruption.

4. Continuous Learning

- The AI systems continuously learn and adapt to new data, ensuring they stay updated with evolving production requirements.

Tribal knowledge is an invaluable asset in manufacturing, but its undocumented and individual-dependent nature limits its scalability and consistency. Machine Vision AI and AOI systems provide a transformative solution, capturing and codifying this expertise into automated processes that enhance production accuracy and efficiency.

By partnering with Intelgic, manufacturers can unlock the full potential of their tribal knowledge, ensuring consistent quality, reduced costs, and a future-ready production environment. Contact Intelgic today to learn how our innovative solutions can revolutionize your manufacturing processes.