Automobile Parts Inspection Automation Using Machine Vision AI

Published on: Jan 14, 2025

Written by: Content team, Intelgic

Automobile Parts Inspection Automation Using Machine Vision AI

The automobile industry is driven by precision, safety, and efficiency. With thousands of components going into a single vehicle, maintaining stringent quality standards is crucial to ensure performance, durability, and safety. Manual inspection methods, while reliable in some cases, are time-consuming, labor-intensive, and prone to inconsistencies. Automation using machine vision and artificial intelligence (AI) has revolutionized the inspection process, delivering unparalleled accuracy, speed, and scalability.

Challenges in Inspecting Automobile Parts

- Complex Geometries:

- Automotive parts often feature intricate designs, making it challenging to inspect using traditional methods.

- Some parts are too large such as doors, bonnets, chassis etc. To inspect these parts, we may need multiple cameras for detailed imaging.

- Some parts are too small such as connectors and other components. We need customized setup to inspect these parts.

- High Production Volumes:

- Thousands of components are manufactured daily, requiring inspection systems that can keep up with production speeds.

- Variety of Materials:

- Parts made from metals, plastics, and composites require adaptable inspection techniques.

- Defect Visibility:

- Detecting defects like cracks, scratches, or dimensional deviations on reflective or textured surfaces is difficult.

- Stringent Standards:

- Automotive regulations demand consistent adherence to quality and safety standards.

Role of Machine Vision AI in Inspection Automation

Machine vision systems integrated with AI provide advanced capabilities for inspecting and verifying automotive parts. These systems combine high-resolution imaging, precise lighting, and intelligent algorithms to identify defects and ensure compliance with quality standards.

Core Components of a Machine Vision AI System

- High-Resolution Cameras:

- Capture detailed images of components, allowing the detection of microscopic defects.

- Lenses:

- Telecentric and autofocus lenses ensure accurate imaging of complex geometries.

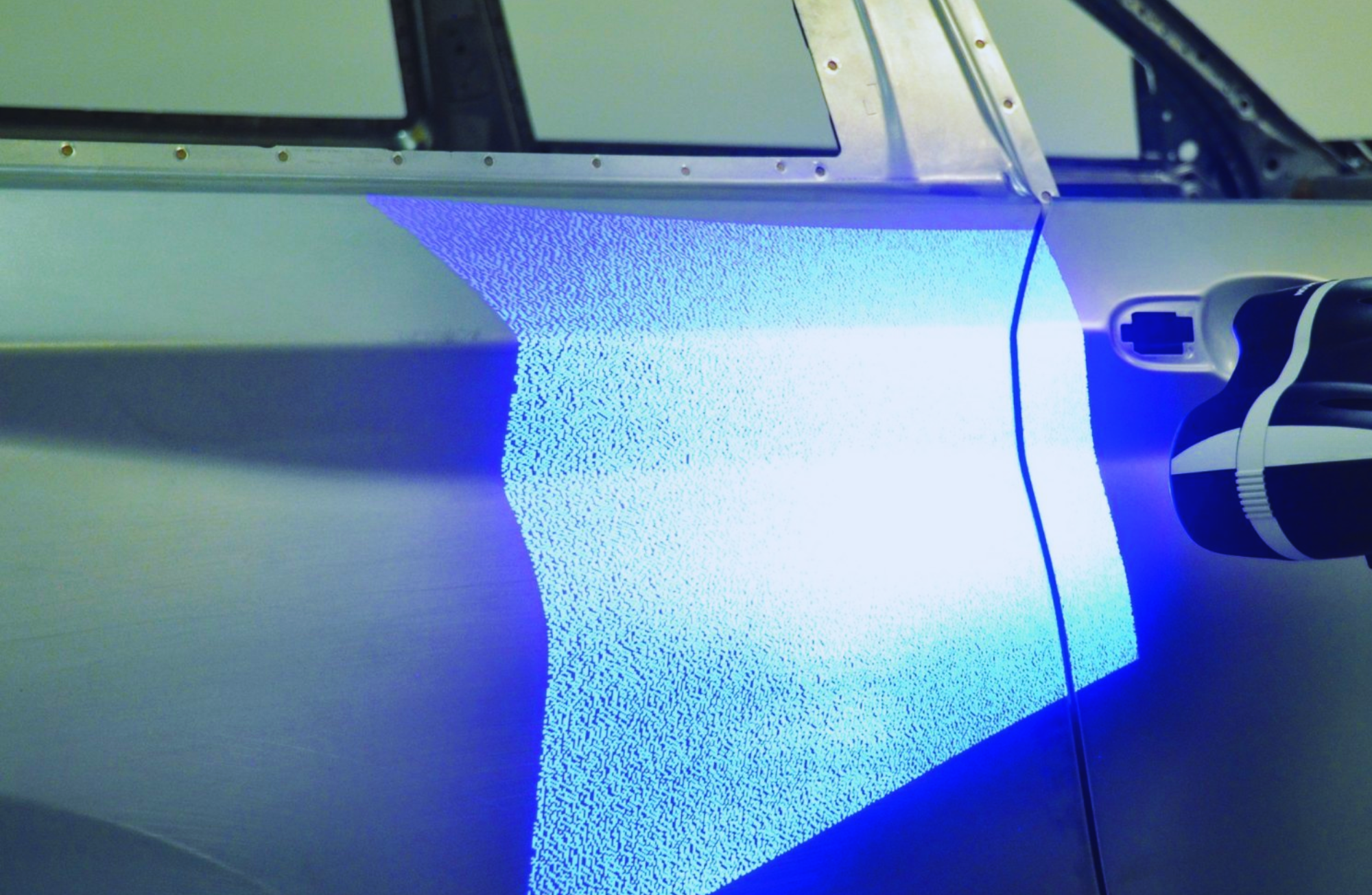

- Lighting Systems:

- Uniform and application-specific lighting, such as coaxial or structured light, enhances defect visibility.

- Robotic Arm Integration:

- For parts with diverse geometric shapes and sizes, robotic arms are used to hold cameras and lights. These arms are programmed to move systematically, capturing detailed images of all surfaces and complex shapes.

- AI and Machine Learning Algorithms:

- Analyze images in real-time to detect and classify defects, even in challenging conditions.

- Conveyor Systems:

- Integrate with inspection systems to ensure seamless part movement and alignment during inspection.

Applications in Automotive Parts Inspection

- Dimensional Measurement:

- Verifies part dimensions against specifications using non-contact measurement techniques.

- Examples: Gears, shafts, and engine blocks.

- Surface Defect Detection:

- Identifies scratches, cracks, dents, and surface irregularities.

- Examples: Body panels, mirrors, and windshields.

- Assembly Verification:

- Confirms proper alignment and placement of components.

- Examples: Wiring harnesses, fasteners, and gaskets.

- Weld and Seam Inspection:

- Ensures the integrity of welds and adhesive seams.

- Examples: Chassis components and body structures.

- Paint and Coating Inspection:

- Detects color inconsistencies, thickness deviations, and surface contaminants.

- Examples: Exterior panels and trims.

- Functional Testing:

- Verifies the operational performance of components like switches and actuators.

Advantages of Machine Vision AI for Automotive Inspection

- High Accuracy and Consistency:

- Eliminates human error, ensuring uniform quality checks.

- Increased Efficiency:

- Performs inspections at production line speeds, minimizing bottlenecks.

- Scalability:

- Easily adapts to varying part sizes, shapes, and materials.

- Cost Savings:

- Reduces rework and waste, improving overall profitability.

- Data-Driven Insights:

- Logs inspection data for traceability and continuous improvement.

- Regulatory Compliance:

- Ensures adherence to automotive safety and quality standards.

Technological Innovations in Machine Vision AI

- Deep Learning Algorithms:

- Train on vast datasets to improve defect detection accuracy over time.

- 3D Imaging and Analysis:

- Captures detailed 3D profiles for inspecting complex geometries and surfaces.

- Edge Computing:

- Processes data locally, enabling real-time inspection without latency.

- Adaptive Inspection Systems:

- Automatically adjust parameters based on part type and defect detection requirements.

Challenges in Implementation

- Initial Setup Costs:

- High initial investment in equipment and integration.

- Training and Calibration:

- Requires skilled personnel for system training and maintenance.

- Complexity of Parts:

- Diverse part designs and materials necessitate robust algorithms and flexible systems.

Intelgic’s Expertise in Automotive Inspection Automation

At Intelgic, we specialize in providing state-of-the-art machine vision solutions tailored to the automotive industry. Our offerings include:

- Customized Inspection Systems:

- Designed to meet the specific needs of your production line.

- AI-Powered Defect Detection:

- Leveraging deep learning to achieve unmatched accuracy and reliability.

- End-to-End Integration:

- Seamless integration with existing production workflows.

- Ongoing Support:

- Comprehensive training, maintenance, and system updates.

Conclusion

Automating the inspection of automobile parts using machine vision AI is a game-changer for the industry. By addressing the challenges of manual inspection and delivering unmatched precision and efficiency, these systems ensure that manufacturers meet the highest standards of quality and safety. With Intelgic’s expertise, you can transform your inspection processes, driving greater productivity, profitability, and customer satisfaction.

Contact us today to learn how we can revolutionize your automobile parts inspection systems with AI-powered machine vision.