Automating microscopic inspection for medical equipment: Replace microscope with AI powered AOI system.

Published on: Mar 25, 2025

Written by: Soumen das

AI-Powered Automation for Microscopic Inspection in Medical Equipment: Replacing traditional microscopes with an advanced AOI system

Medical equipment manufacturing demands an exceptionally high degree of precision, accuracy, and consistency. Traditional inspection methods involving microscopes, though common, present numerous challenges such as inefficiency, inconsistency, and susceptibility to human error, which can reach error rates exceeding 15%. To meet the stringent quality requirements inherent in medical device production, an automated and highly accurate inspection process is indispensable. AI-powered Automated Optical Inspection (AOI) systems represent a transformative solution, delivering superior precision, consistency, and efficiency in microscopic inspections.

Limitations of Manual Microscopic Inspection

Microscopic inspection traditionally involves human inspectors using microscopes to manually evaluate medical equipment placed in a stationary inspection environment. While this approach is widely used, it comes with significant limitations:

- Human Error and Inconsistency: Inspection accuracy heavily depends on human skill, experience, fatigue levels, and subjective judgment, leading to variability and errors, sometimes surpassing 15%.

- Time-Consuming: Manual inspection is inherently slow, limiting throughput and negatively affecting productivity.

- Scalability Issues: Scaling manual inspection processes to meet growing production demands is challenging and costly.

Intelgic’s AI-Powered Machine Vision Solution

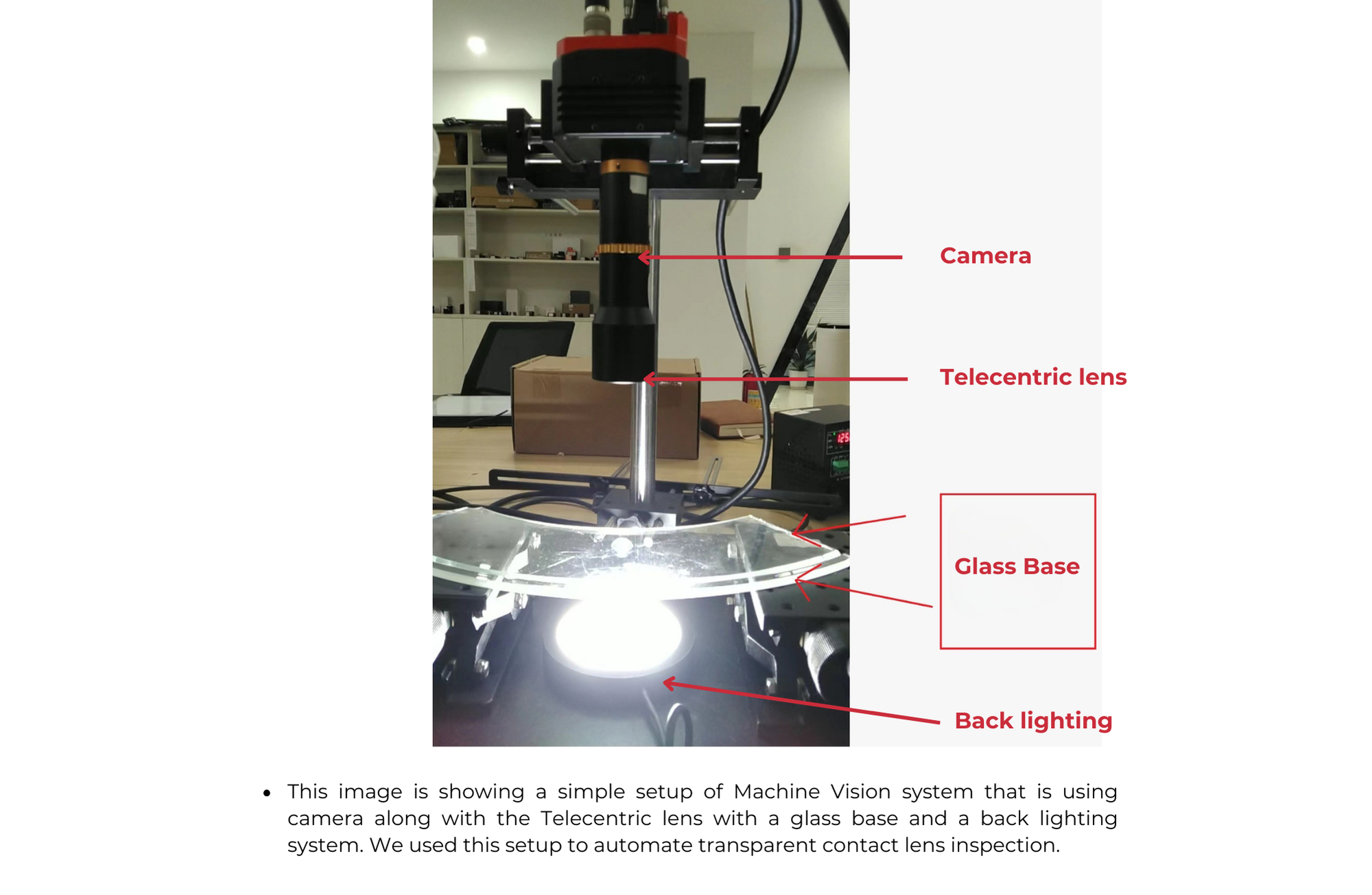

Intelgic replaces conventional microscopes with a complete Automated Optical Inspection (AOI) system powered by customized imaging sensor, lights, specialized lens and advanced artificial intelligence (AI) algorithms. Our AOI solutions are specifically designed to inspect highly sensitive medical equipment such as contact lenses, stents, and other precision components.

Tailored Solutions for Complex Inspection Needs

Medical equipment inspection often involves sensitive materials, varied shapes, sizes, and transparency levels. Intelgic carefully assesses each product's specific attributes—shape, size, material transparency, and the required inspection process—before custom designing and assembling cameras, lenses, and lighting configurations. This comprehensive customization is critical for effective AOI of sensitive medical devices.

Intelgic’s AOI systems incorporate:

1. Specialized Image Sensors and Cameras

Intelgic uses specialized image sensors within high-end machine vision cameras, optimized for microscopic and highly detailed inspections. These sensors ensure exceptional clarity, resolution, and sensitivity required for detecting minute defects.

2. Precision Optical Lens Systems

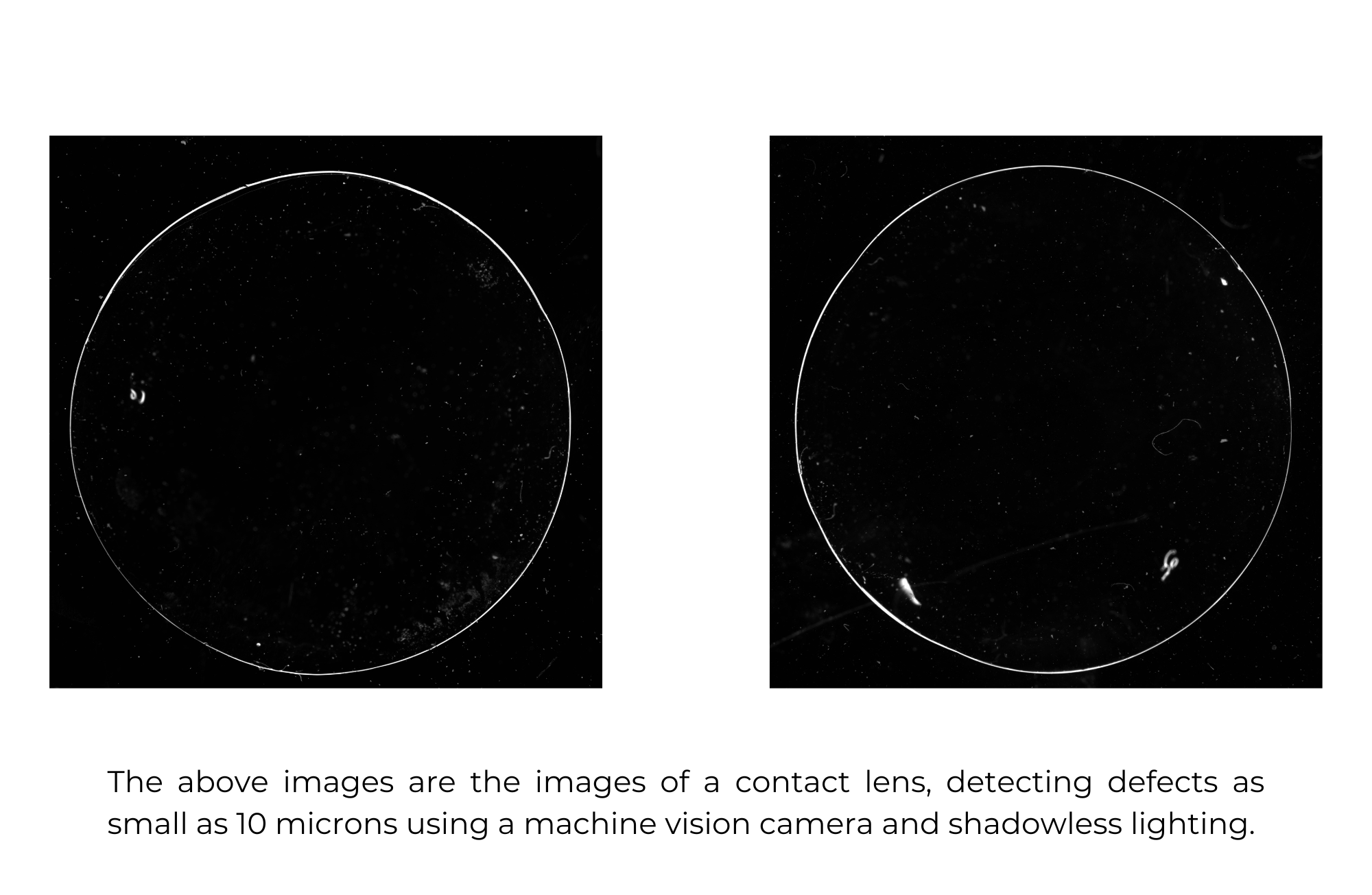

Intelgic carefully designs specialized optical lenses to suit specific medical inspection needs. Each lens is precisely engineered to capture high-resolution images necessary for detecting defects even smaller than 10 microns.

3. Customized Lighting Solutions

Recognizing that optimal illumination is crucial, Intelgic meticulously designs lighting setups customized for each medical device inspection scenario. This includes diffused lighting, coaxial illumination, angled lighting, and other tailored techniques to enhance defect visibility effectively.

4. Customization through 3D Printing

Each medical device or component can have unique inspection requirements, necessitating customized support and fixtures for effective inspection. At Intelgic, advanced 3D printing technology is employed to rapidly design and fabricate tailored inspection fixtures and device supports. This capability ensures precise positioning, orientation, and stability of inspection targets, further improving inspection accuracy and efficiency.

5. Integrating Robotic Automation

To further enhance the flexibility and efficiency of AOI systems, Intelgic integrates robotic arms for advanced automation. Robotic systems precisely manipulate inspection targets, adjust camera positioning dynamically, and optimize the inspection workflow. This automation significantly reduces manual setup and intervention, allowing continuous, consistent inspection processes and rapid adaptation to varied inspection requirements.

6. AI Algorithms and Image Processing

AI-powered AOI systems leverage sophisticated machine learning models capable of rapidly analyzing high-resolution images to identify defects reliably. Deep learning techniques enhance detection accuracy, drastically reducing false positives and negatives.

Advantages of AI-Powered AOI Systems

Integrating AI-powered AOI systems into the inspection process offers numerous benefits:

- Enhanced Accuracy and Consistency: AI algorithms can be trained to detect specific defects with high precision, ensuring consistent quality across all inspected devices. For instance, Akridata's Inspection Studio utilizes advanced AI and deep learning to detect defects in medical devices, leading to a 40% reduction in false positives and a 30% reduction in false negatives.

- Increased Throughput: Automated systems can operate continuously without fatigue, significantly increasing the number of inspections performed and reducing bottlenecks in the production line.

- Micron-Level Defect Detection: High-resolution imaging combined with AI enables the detection of defects at the micron level, ensuring that even the smallest imperfections are identified. For example, ATS Industrial Automation achieved micron-level accuracy in suture manufacturing using advanced automation and vision systems.

Data-Driven Insights: AI systems can analyze vast amounts of inspection data to identify patterns and root causes of defects, facilitating continuous improvement in manufacturing processes.

AI-powered Automated Optical Inspection systems, enhanced by advanced optics, custom lighting, 3D printing for customization, and robotic automation, represent a significant advancement for medical device inspections. These systems not only enhance precision and consistency but also significantly improve production efficiency and reduce errors, revolutionizing quality control processes in the medical manufacturing industry.

Intelgic specializes in developing and implementing such high-end AOI solutions, positioning medical device manufacturers at the forefront of technological innovation, quality assurance, and operational excellence.