Automobile Parts Inspection Automation Using Machine Vision AI

Published on: Jul 16, 2025

Written by: Content team, Intelgic

Introduction

In modern automotive manufacturing, quality control is non-negotiable. As vehicles evolve with intricate electronic, mechanical, and composite parts, ensuring that every component meets exacting standards is vital for safety, performance, and brand reputation. Manual inspection techniques are no longer sufficient due to limitations in consistency, speed, and traceability. This is where machine vision and AI-driven visual inspection systems are revolutionizing the industry.

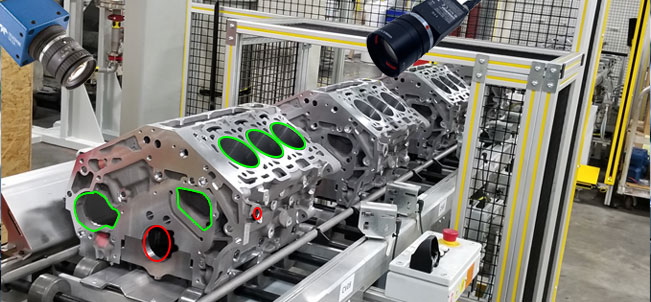

Automated Optical Inspection (AOI) systems powered by high-resolution cameras, custom lighting, and AI models can inspect complex automotive parts—ranging from engine assemblies and gearbox housings to wiring harnesses and control modules—with high accuracy and repeatability. These systems operate on production lines in real-time, ensuring every defect is caught before it reaches the customer.

Challenges in Inspecting Complex Automotive Part

- Geometric Complexity: Parts with intricate geometries such as cylinder heads, turbochargers, or connectors have non-planar surfaces and multiple inspection zones.

- Material Diversity: Varying reflectivity (e.g., aluminum, plastics, rubber, composites) complicates consistent imaging.

- Defect Variety: From cracks, scratches, burrs, and deformations to assembly errors and missing components.

- Tight Tolerances: Dimensions and visual characteristics must be measured within micron-level tolerances.

- Production Speed: High-speed lines demand sub-second inspection cycles.

- Traceability: Inspection data must be logged for warranty validation and process analytics.

Key Challenges in Automotive Parts Inspection

Inspecting automotive components with machine vision and AI comes with a unique set of challenges due to the complexity of the parts, materials used, and dynamic production environments. Understanding these challenges is crucial to designing a robust and reliable inspection solution.

1. Geometric Complexity: Complex Shapes and Sizes

Automotive parts such as turbochargers, cylinder heads, housings, and connectors often have non-uniform geometries, curves, holes, cavities, and undercuts. Capturing an entire part in one image is not feasible due to:

- Limited field of view (FOV) of cameras.

- Uneven surfaces and depth variations.

- Requirement to inspect multiple sides and angles.

Solution: The FOV is divided into multiple regions, and images are captured in segments using:

- Multi-camera setups

- Motorized movement of the part or camera system

Image stitching for complete surface analysis

2. Material Diversity: Shiny and Reflective Surfaces

Parts made from polished metals (e.g., aluminum, steel, chrome) pose serious imaging issues due to:

- Specular reflections blinding the camera

- False positives from glare artifacts

Solution:

- Use of shadowless lighting such as dome lights or diffused coaxial setups

- Low-angle dark field illumination to enhance surface defects while minimizing reflection

- Adjusting exposure and polarization filters

3. Ambient Lighting Interference

Factory lighting or sunlight entering the inspection zone can:

- Alter image brightness and contrast

- Create shadows or highlight inconsistencies

- Obscure fine defects or distort feature visibility

Solution:

- Enclose the inspection area in a light-controlled dark room

- Isolate the camera and lighting system inside custom imaging enclosures

Use constant-intensity industrial lighting controlled by a lighting controller

4. Moving Parts on Conveyor Belts

High-speed production lines require the inspection system to match the line speed. However:

- Parts may shift, vibrate, or rotate unpredictably

- Motion blur can degrade image quality

- Existing conveyor designs may not include sections suitable for inspection

Solution:

- Integrate encoders or triggers to synchronize image capture with conveyor motion

- Use strobing or short-exposure lighting to freeze motion

Redesign or add controlled sections in conveyor lines for inspection-specific zones

5. Legacy Production Lines Not Designed for Vision Inspection

Most existing automotive production setups were not initially built with inspection automation in mind:

- Lack of clear space for cameras or lighting

- No provision for motion synchronization or part isolation

- Inconsistent part orientation due to manual or legacy material handling

Solution:

- Retrofit production lines with modular inspection stations

- Add part positioning jigs, fixtures, or robotic handlers

Use software-based AI orientation detection to compensate for random part placement

6. Defect Variety

Automotive parts exhibit a wide range of defect types, such as:

- Surface defects: cracks, scratches, burrs, and pits.

- Dimensional issues: warping, shrinkage.

- Assembly errors: missing fasteners, misaligned components, or incorrect parts.

Solution: Train AI models on multi-class defect datasets to detect both surface anomalies and structural inconsistencies.

7. Tight Tolerances

Automotive quality standards demand micron-level precision in both dimensional and visual inspections:

- A few microns can be the difference between a pass and a failure.

- Traditional image processing may not suffice.

Solution: Use telecentric lenses, calibrated setups, and AI-enhanced sub-pixel measurement techniques for high-accuracy verification.

8. Production Speed Requirements

Vision inspection must operate at line speed without delaying production:

- Cycle times may be less than 500 milliseconds per part.

- Simultaneous multi-feature inspection is often required.

Solution: Utilize high-speed cameras, parallel processing, GPU acceleration, and optimized AI inference pipelines.

9. Data Logging and Traceability

Manufacturers must track inspection data for:

- Warranty validation

- Regulatory compliance

- Root cause analysis and traceability

Solution: AI inspection systems must log images, defect coordinates, pass/fail status, part ID (via barcode/QR), and timestamps. Reports can be pushed to cloud dashboards or MES systems for traceability.

System Architecture of a Vision-Based Inspection Setup

1. Machine Vision Cameras

- Area Scan Cameras for static inspections.

- Line Scan Cameras for cylindrical or continuously moving parts (e.g., brake rotors, shafts).

- 3D Cameras (structured light, laser triangulation) for height and profile inspection.

2. Lenses

- Telecentric lenses eliminate parallax and distortion for accurate measurement.

- Zoom lenses for multi-sized part handling.

3. Industrial Lighting

Proper illumination is essential to highlight defects:

- Coaxial lighting for surface cracks on shiny metals.

- Dome lights to reduce glare on curved parts.

- Dark field lighting to expose micro-scratches or dust.

- Backlighting for silhouette and edge profile validation.

- Multi-wavelength lighting (Red/Blue/White) based on surface and material type.

4. Image Acquisition & Processing

High-speed frame grabbers and GPU-based PC controllers capture and preprocess images in real time, feeding them to AI models.

5. AI-Based Inspection Software

Intelgic’s Live Vision AI or equivalent software performs:

- Object detection

- Anomaly detection

- Dimensional measurement

- Defect localization (with coordinates)

Part classification (OK/NG, defect type, severity)

AI and Machine Learning in Inspection

AI brings powerful pattern recognition and adaptability to vision inspection. Here’s how:

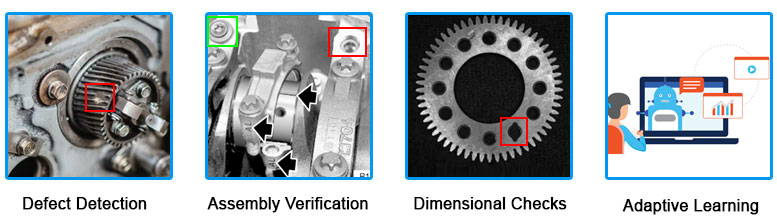

Defect Detection

- Trained models detect scratches, dents, cracks, and stains with pixel-level precision.

- Deep learning models (e.g., CNNs, Transformers) adapt to varying surface textures and lighting conditions.

Assembly Verification

- AI can recognize complex assemblies such as wire harnesses, confirming the presence, position, and orientation of each connector or fastener.

Dimensional Checks

- ML algorithms perform sub-micron measurements and validate distances, angles, hole diameters, and profiles without physical contact.

Adaptive Learning

- The system continuously improves through supervised feedback and new data, reducing false positives and increasing accuracy.

Automated Motion Systems for Complete Imaging

In the inspection of complex automotive parts—such as engine blocks, differential housings, brake calipers, or steering knuckles—certain surfaces may be hidden or partially visible from a fixed camera angle. To ensure complete coverage and eliminate blind spots, an automated motion system is often required.

These systems move either the camera and lighting setup or the object itself across X, Y, and Z axes or along rotational axes to expose every surface to the vision system. This enables thorough imaging before AI analysis begins.

When Motion Is Required

- Parts have internal cavities or complex contours.

- Part surfaces are located at multiple height levels.

- Certain angles or zones are shadowed under static lighting.

- The inspection process involves 3D profile or height measurement.

Motion System Configurations

- XY Gantry Stages: Camera and lighting move horizontally over the part for large components.

- Rotary Stages: The part rotates (e.g., crankshafts, gears) to expose all sides to a stationary camera.

- Z-Axis Movement: For adjusting focal depth or imaging features at different height levels.

- Multi-Axis Robotic Arms: Provide flexibility for inspecting parts with arbitrary geometries and orientations.

Synchronized Imaging

These motion systems are synchronized with the camera triggering and lighting to capture sharp, distortion-free images at predefined locations or angles. For high accuracy, encoder feedback and PLC control ensure precise positioning, timing, and repeatability.

Result: Optimal Image Acquisition

By combining automated motion with smart vision, the system ensures that:

- Every relevant surface of the part is imaged clearly.

- Lighting is optimized for each angle to highlight defects.

- 2D, 3D, or multi-view imaging data is available for AI-based inspection.

This motion-assisted imaging stage is critical for achieving reliable, comprehensive inspection of intricate automotive components.

Key Use Cases in Automotive Industry

|

Component |

Inspection Goals |

|

Cylinder Head / Engine Block |

Crack detection, thread presence, surface porosity, valve seat check |

|

Brake System |

Rotor profile measurement, pad wear detection, surface roughness |

|

ECU / Control Modules |

Solder joint inspection, label verification, connector pin count |

|

Wiring Harness |

Connector match, pin orientation, color coding check |

|

Gearbox & Transmission |

Seal presence, bore diameter, oil leakage detection |

|

Headlights / Lamp Units |

Surface defects, screw tightening, reflector alignment |

Integration with Manufacturing Systems

- PLC/SCADA Integration: Seamless triggering of inspection based on part movement.

- Barcode/QR Code Readers: To track individual parts and tie inspection results to serial numbers.

- Cloud Dashboard: Inspection summary reports with search, filter, and defect history for each part or batch.

- AI Training Interface: Engineers can create new templates, train AI models, and define acceptable thresholds without coding.

Benefits of AI-Powered Vision Inspection in Automotive Manufacturing

- Higher Detection Accuracy: Consistently detects even micro-level defects across shifts and lighting conditions.

- Real-time Feedback: Instant alerts for rework or machine adjustment.

- Productivity Boost: 24/7 operation with minimal downtime.

- Improved Quality: Reduced warranty claims and better end-user satisfaction.

- Scalable & Configurable: New models or parts can be added quickly through data collection and AI training.

- Complete Traceability: Part-wise inspection data for audit, compliance, and continuous improvement.

AI-driven machine vision systems are the cornerstone of intelligent, scalable, and consistent quality control in modern automotive manufacturing. As automotive parts become more complex and customer expectations continue to rise, integrating vision and AI-based inspection is no longer optional—it’s essential.

Intelgic’s end-to-end inspection solutions, combining custom imaging systems, smart lighting, and Live Vision AI software, ensure that automotive manufacturers meet the highest standards of quality, safety, and reliability.