Aesthetic Defect Detection

Published on: Jan 10, 2025

Written by: Content team, Intelgic

Introduction to Aesthetic Defect Detection

Aesthetic defects, such as scratches, dents, color inconsistencies, or surface irregularities, can significantly impact the perceived quality of a product. Industries like automotive, electronics, consumer goods, and luxury manufacturing place a high emphasis on flawless aesthetics, as even minor imperfections can diminish customer satisfaction and brand reputation. Aesthetic defect detection is the process of identifying and classifying surface defects to ensure that products meet stringent quality standards. Modern advancements in machine vision and AI have revolutionized this process, enabling faster, more accurate, and consistent inspection.

What Are Aesthetic Defects?

Aesthetic defects refer to any visual imperfections on a product’s surface or part that affect its appearance but not necessarily its functionality. Common examples include:

- Surface Scratches and Scuffs:

- Caused by handling, machining, or material flaws.

- Dents and Deformations:

- Resulting from impacts or manufacturing errors.

- Color Variations:

- Uneven or incorrect application of coatings, paints, or finishes.

- Texture Inconsistencies:

- Variations in surface smoothness or patterns.

- Contaminations:

- Dust, oil, or foreign particles embedded during production.

- Assembly Misalignments:

- Visible gaps or offsets in assembled parts.

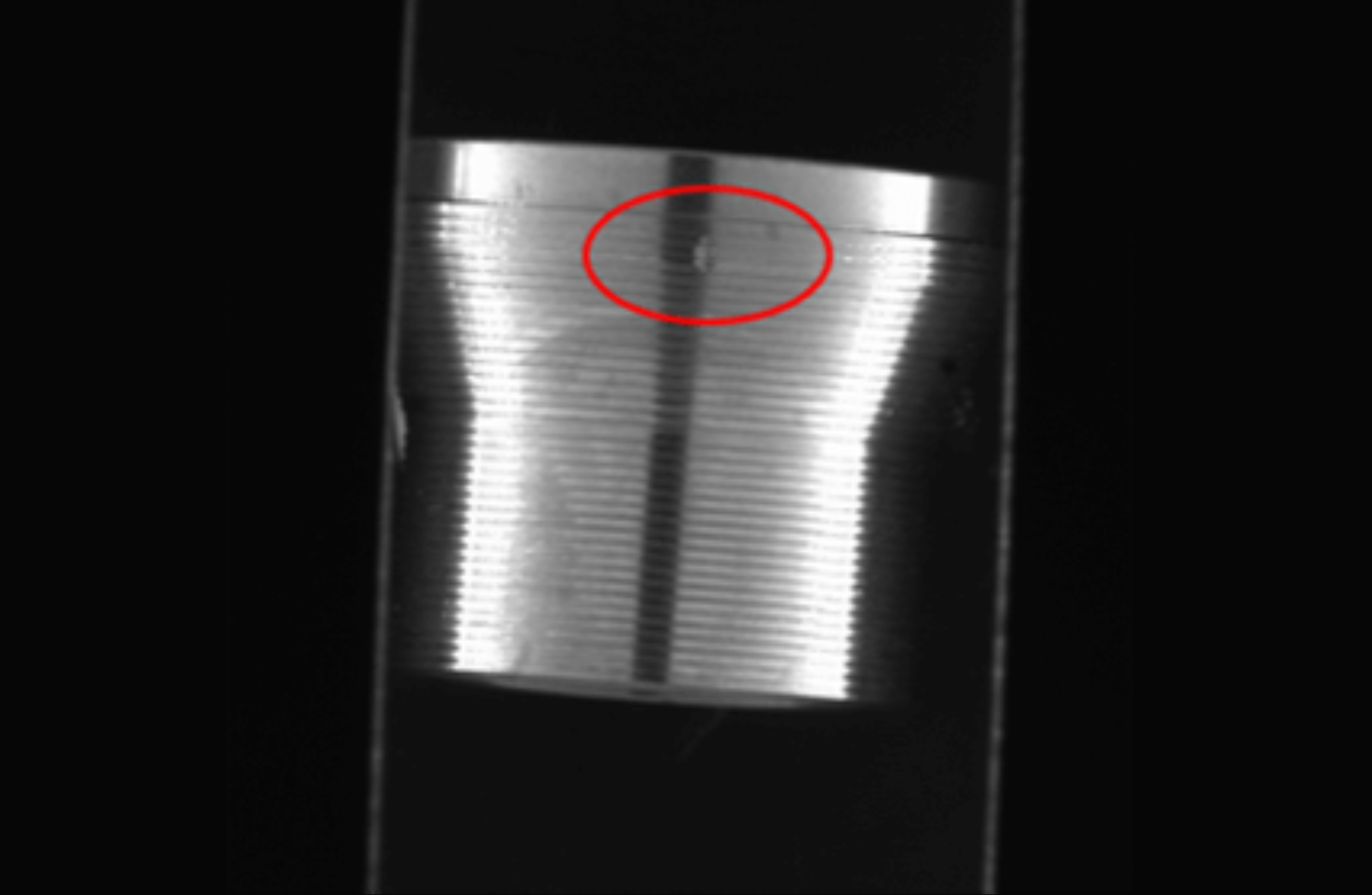

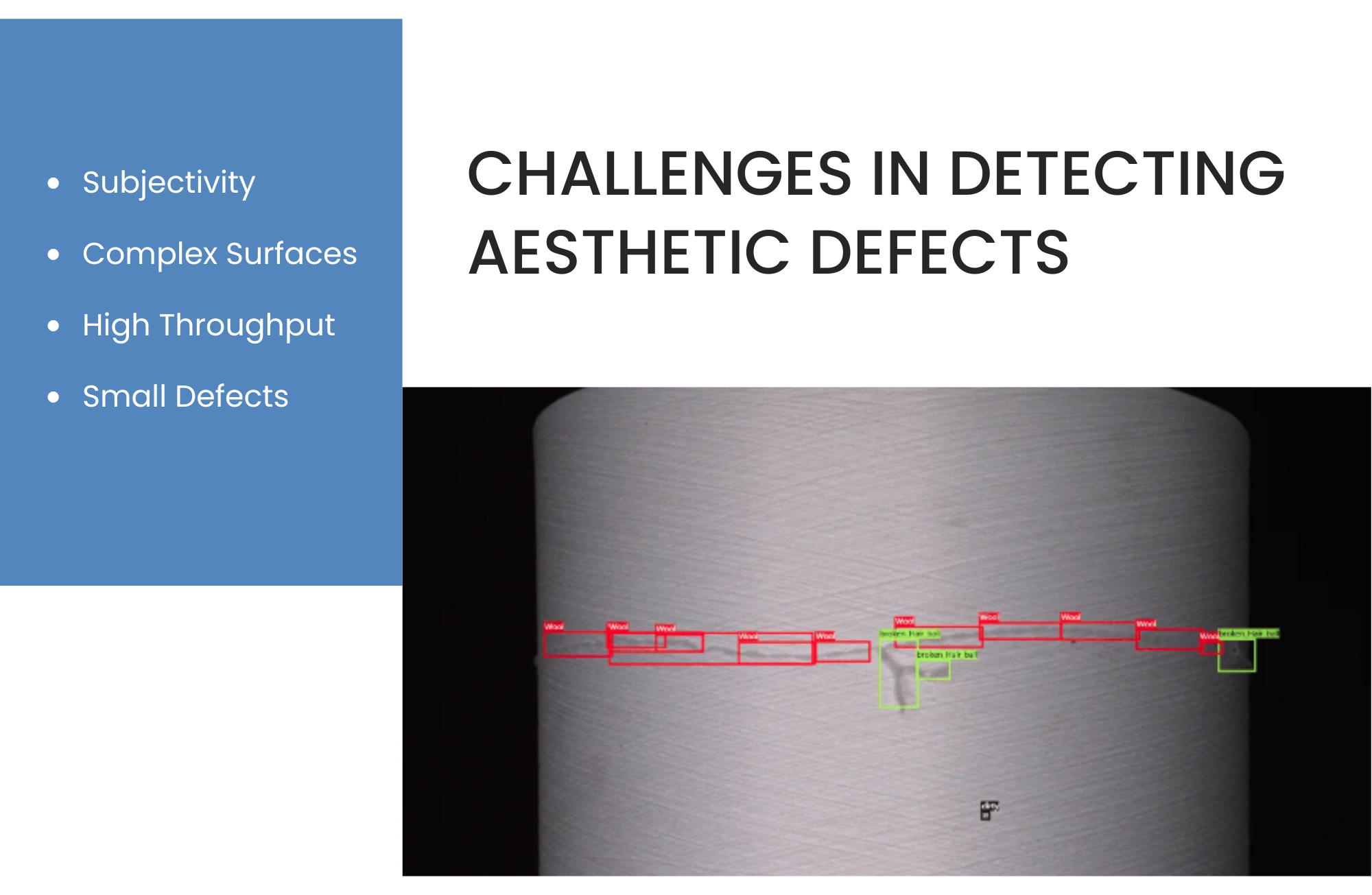

Challenges in Detecting Aesthetic Defects

- Subjectivity:

- Human inspectors often rely on subjective judgment, leading to inconsistencies.

- Complex Surfaces:

- Textured, curved, or reflective surfaces pose challenges for traditional inspection methods.

- High Throughput:

- Inspecting thousands of parts per hour manually is time-consuming and error-prone.

- Small Defects:

- Minor imperfections, especially on high-gloss or matte finishes, are difficult to detect with the naked eye.

Aesthetic Defect Detection Using Machine Vision

Machine vision systems equipped with advanced cameras, lighting, and AI algorithms address these challenges, offering a robust solution for aesthetic defect detection.

Key Components of Machine Vision Systems

- High-Resolution Cameras:

- Capture fine details of surfaces and parts with high precision.

- Area scan or line scan cameras are used depending on the application.

- Lighting Systems:

- Proper illumination is critical for defect detection.

- Types of lighting include:

- Ring lights for uniform illumination.

- Coaxial lights for reflective surfaces.

- Structured lighting to highlight surface irregularities.

- Lenses:

- Fixed focal, telecentric, or autofocus lenses ensure accurate imaging based on defect size and surface geometry.

- AI and Computer Vision Algorithms:

- Analyze captured images to detect, classify, and quantify defects.

- Employ deep learning models trained on diverse defect datasets for enhanced accuracy.

- Inspection Software:

- Provides real-time analysis, defect visualization, and actionable insights.

Applications of Aesthetic Defect Detection

- Automotive Industry:

- Inspecting painted car bodies for scratches, dents, and paint runs.

- Checking interiors for texture and finish consistency.

- Consumer Electronics:

- Detecting scratches or blemishes on smartphone screens, casings, and keypads.

- Luxury Goods Manufacturing:

- Ensuring flawless finishes on watches, jewelry, and high-end accessories.

- Aerospace Components:

- Inspecting critical parts for surface integrity to maintain high safety standards.

- Packaging:

- Checking labels, seals, and packaging surfaces for defects and inconsistencies.

Advantages of Automated Aesthetic Defect Detection

- High Accuracy:

- Consistently detects even the smallest defects invisible to the naked eye.

- Increased Efficiency:

- Speeds up the inspection process, accommodating high production rates.

- Objectivity:

- Eliminates subjectivity, ensuring consistent quality standards.

- Traceability:

- Logs inspection data for future analysis and quality improvement.

- Cost Savings:

- Reduces rework, material waste, and customer returns.

Factors to Consider When Implementing an Aesthetic Defect Detection System

- Surface Characteristics:

- Consider the texture, reflectivity, and geometry of the target surface.

- Defect Types:

- Define the types and sizes of defects that need to be detected.

- Production Speed:

- Choose a system capable of matching your throughput requirements.

- Lighting Conditions:

- Select appropriate lighting to enhance defect visibility.

- Integration with Existing Systems:

- Ensure compatibility with production lines and quality control workflows.

Intelgic’s Expertise in Aesthetic Defect Detection

At Intelgic, we specialize in designing and implementing advanced aesthetic defect detection systems tailored to your specific needs. Our solutions include:

- Customized Machine Vision Systems:

- Tailored to handle unique surface characteristics and defect requirements.

- AI-Driven Inspection Software:

- Leveraging deep learning to deliver unmatched detection accuracy.

- End-to-End Integration:

- Seamless integration with production lines for real-time defect detection and reporting.

- Ongoing Support:

- Providing training, maintenance, and system upgrades to ensure sustained performance.

Aesthetic defect detection is critical for maintaining product quality and customer satisfaction. By leveraging machine vision and AI, manufacturers can achieve unprecedented accuracy, speed, and consistency in identifying surface defects. Intelgic’s expertise in this domain ensures that your products meet the highest aesthetic standards, enhancing your brand’s reputation and competitive edge.

Contact us today to learn how our aesthetic defect detection solutions can transform your quality control processes.